Spiral drilling machine

A technology of auger drilling rigs and hexagonal bolts, which is applied in the direction of rotary drilling rigs, rotary drilling, mechanical equipment, etc. It can solve the problems of inconvenient installation and maintenance, large volume and heavy weight of large displacement motors, and achieve reliable structure, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

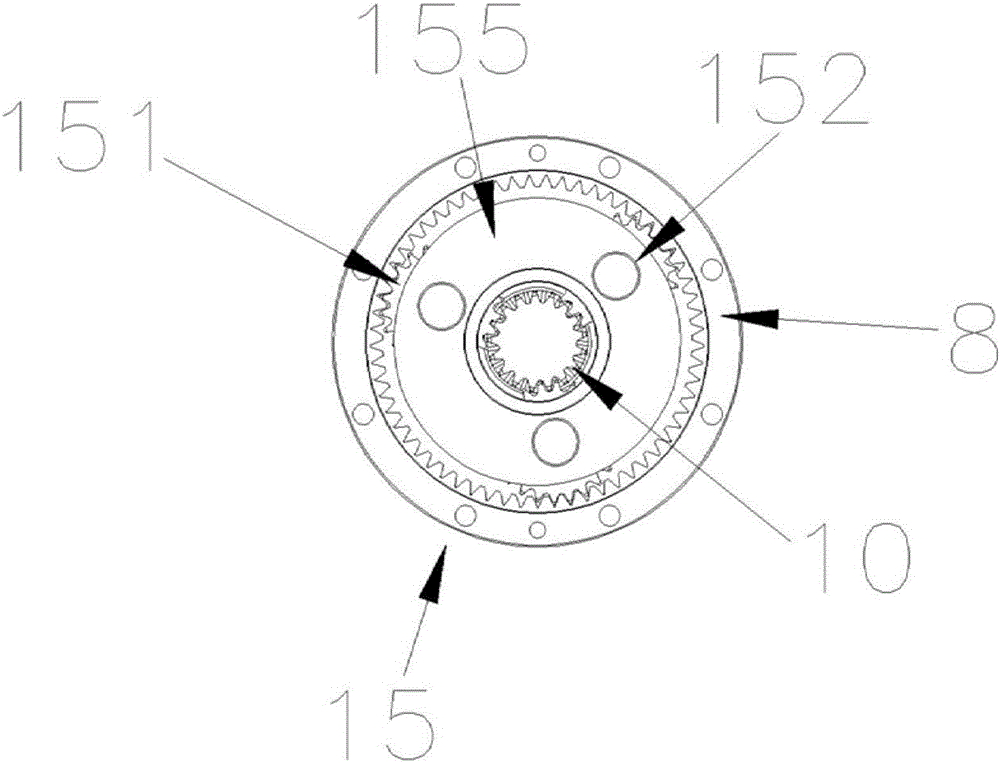

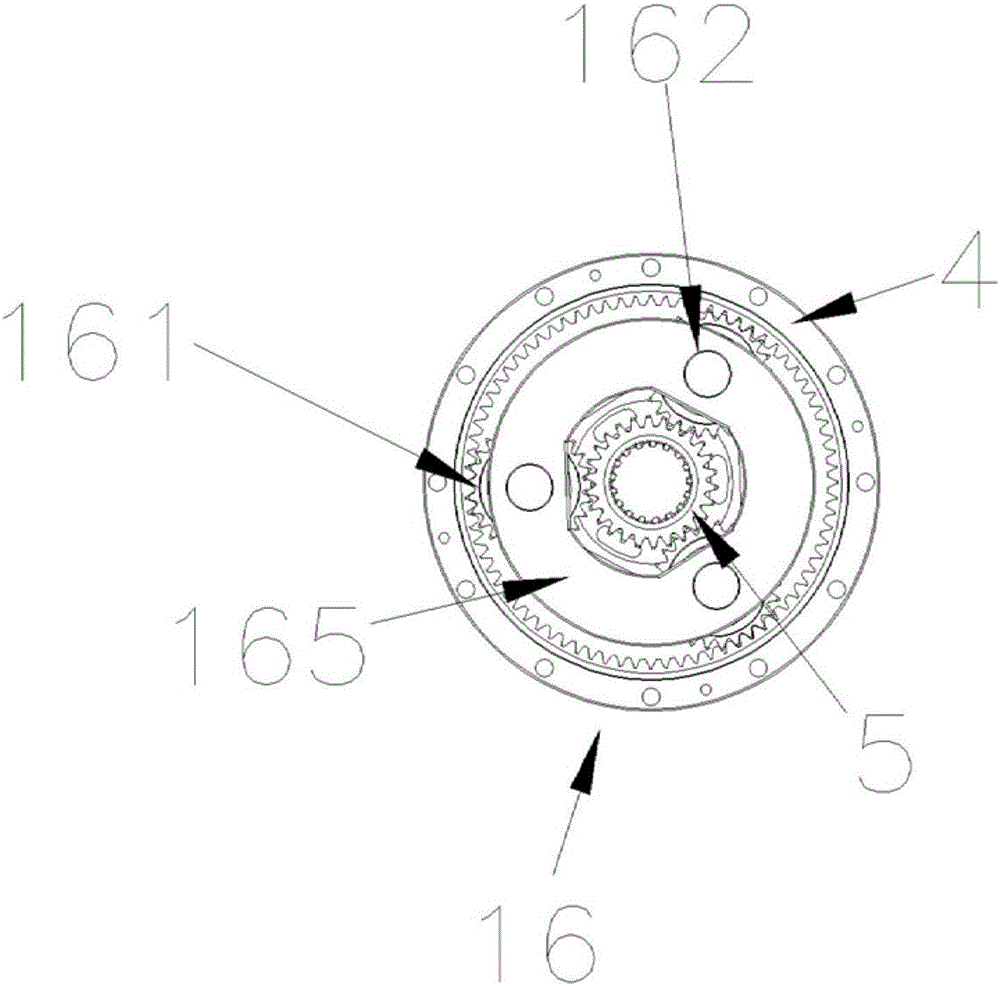

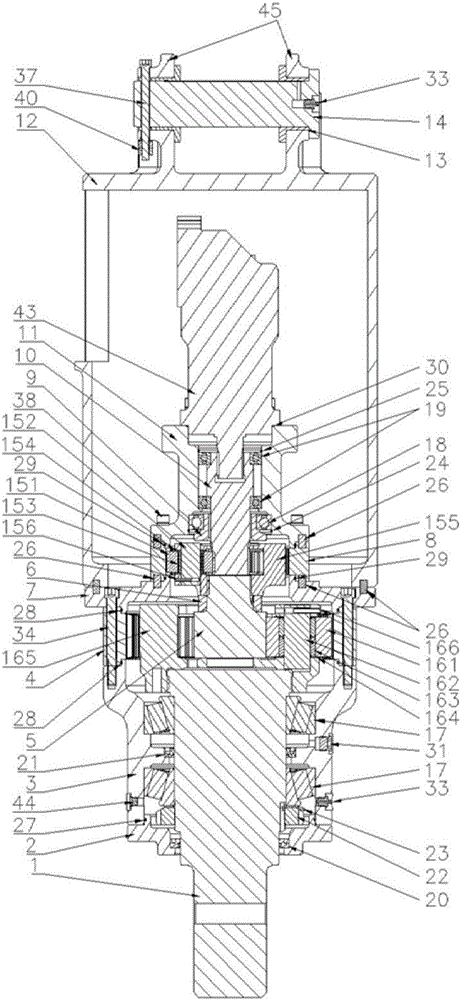

[0024] like figure 1 As shown, the present invention provides an auger drilling machine, including an oil seal cover 2, above which a bearing seat 3, a secondary rotary assembly 16, a flange 7 and a motor housing 12 are sequentially assembled; Positioning pins 26 are also provided at the joints between the flange 7 and the motor housing 12; the flange 7 and the motor housing 12 are connected and fixed by hexagon socket bolts 336; the oil seal cover 2 and the bearing The inner side of the seat 3 is assembled with the output shaft 1, and the oil seal cover 2 and the bearing seat 3 are fixed by hexagon socket bolts 639; the junction of the oil seal cover 2 and the bearing seat 3 is provided with an O-ring One 27; the bearing seat 3 is provided with plug one 31, plug two 44 and grease fitting 33; one end of the output shaft 1 passes through the bearing seat 3 and the oil seal cover 2 for external load, and the other One end engages with the secondary slewing assembly 16;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com