Steel bar binding assembly line process

A technology of steel bar binding and flowing water, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of high comprehensive skill requirements for workers and insufficient labor force, so as to improve construction quality, reduce loss and waste, and improve labor difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

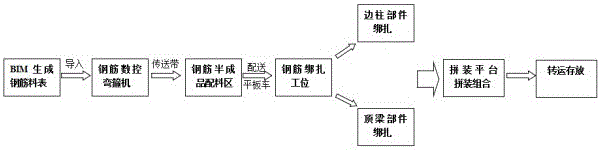

[0022] Such as figure 1 The shown steel bar binding flow process includes the following steps:

[0023] Step 1. First, the steel bar in the drawing is automatically generated by BIM technology, and the generated steel bar material list is imported into the steel bar CNC bending machine. The CNC hoop bending machine is CNC cut according to the model to form a semi-finished steel bar;

[0024] Step 2, transfer the semi-finished steel bar in step 1 to the semi-finished steel bar batching area through the conveyor belt, and the batching specialist will batch the steel bar according to the number of the steel cage;

[0025] Step 3, the materials prepared in step 2 are delivered to the binding station of side column parts of the wallboard and the binding station of top beam parts of the wallboard respectively through the distribution flatbed truck, and the wallboard is completed by the ironworkers of each binding station Binding of side column parts and wall panel top beam parts; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com