Preparation method of fruit and vegetable preservative paper

A fruit and vegetable preservation and preservative technology, which is applied in the fields of fruit and vegetable preservation, chemical instruments and methods, paper, etc., can solve problems such as high cost and human injury, and achieve the effects of reducing loss and waste, maintaining freshness, and delaying dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

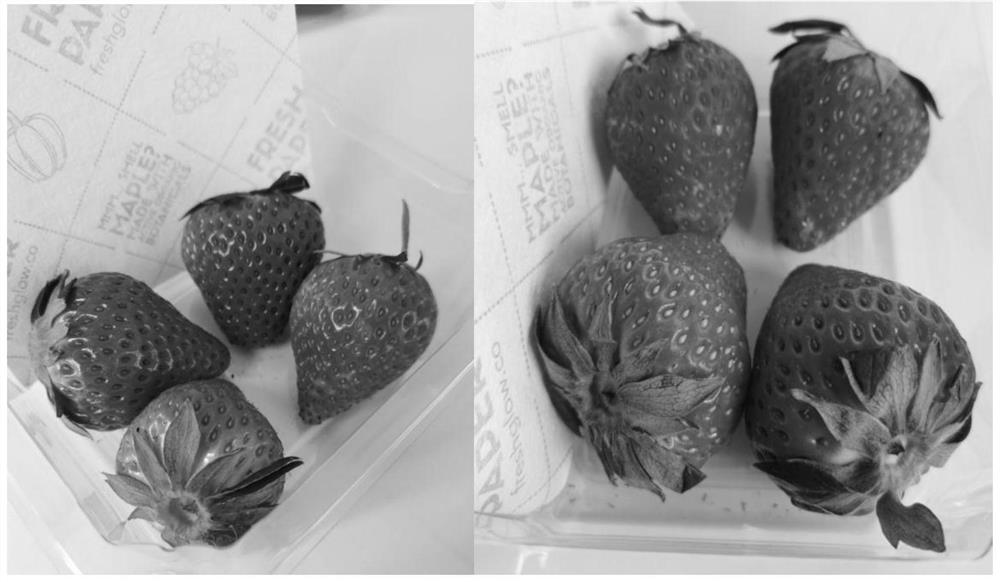

Image

Examples

preparation example Construction

[0041] A preparation method of fruit and vegetable fresh-keeping paper, comprising the following preparation methods;

[0042] (1) Cinnamon bark extract, galangal extract, cohosh extract, peppermint extract, atractylodes extract by mass ratio 0.5-1:1-3:0.1-0.5:1-2:0.6-1.2:0.5-1 Compounded into 0.05-2wt% mixed preservative;

[0043] (2) Prepare the adsorption solution by mixing porous adsorption capsules and deionized water at a mass ratio of 1:10-15, then mix and stir the adsorption solution and mixed preservative at a mass ratio of 5-10:1, let it stand, and suction filter 1. Prepare fresh-keeping capsules after drying;

[0044] (3) dissolving starch in water to prepare a 5-10wt% starch solution;

[0045] (4) Chitosan is dissolved in 1-2wt% acetic acid aqueous solution to prepare 1-2wt% chitosan solution;

[0046] (5) mixing starch solution, chitosan solution and fresh-keeping capsules with deionized water in a mass ratio of 10-15:8-10:1-3 to prepare fresh-keeping capsules ...

Embodiment 1

[0054] A preparation method of fruit and vegetable fresh-keeping paper, comprising the following preparation methods;

[0055] (1) cassia bark extract, galangal extract, cohosh extract, peppermint extract, and atractylodes extract are compounded into a 1wt% mixed preservative in a mass ratio of 0.8:2:0.3:1.5:0.9:0.7;

[0056] (2) Prepare the adsorption solution by mixing porous adsorption capsules and deionized water at a mass ratio of 1:13, then mix and stir the adsorption solution and the mixed preservative at a mass ratio of 8:1 and let it stand, suction filter and dry Prepare fresh-keeping capsules;

[0057] (3) dissolving starch in water to prepare 8wt% starch solution;

[0058] (4) Chitosan is dissolved in 1.5wt% acetic acid aqueous solution to prepare 1.5wt% chitosan solution;

[0059] (5) mixing starch solution, chitosan solution and fresh-keeping capsules with deionized water in a mass ratio of 12:9:2 to prepare fresh-keeping capsules with a concentration of 1.5wt% ...

Embodiment 2

[0068] A method for preparing fresh-keeping paper for fruits and vegetables, comprising the following preparation methods;

[0069] (1) cassia bark extract, galangal extract, cohosh extract, peppermint extract, and herb extract are compounded into a 0.05wt% mixed preservative in a mass ratio of 0.5:1:0.1:1:0.6:0.5;

[0070] (2) Prepare the adsorption solution by mixing porous adsorption capsules and deionized water at a mass ratio of 1:10, then mix and stir the adsorption solution and the mixed preservative at a mass ratio of 5:1 and let it stand, suction filter and dry Prepare fresh-keeping capsules;

[0071] (3) dissolving starch in water to prepare a 5wt% starch solution;

[0072] (4) Chitosan is dissolved in 1wt% acetic acid aqueous solution to prepare 1wt% chitosan solution;

[0073] (5) mixing starch solution, chitosan solution and fresh-keeping capsules with deionized water in a mass ratio of 10:8:1 to prepare fresh-keeping capsules with a concentration of 1wt% sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com