Glass fiber yarn coating device with power mechanism

A technology of power mechanism and glass fiber, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile processing machine accessories, etc., can solve the problems of low production efficiency, glass fiber yarn coating, etc., achieve convenient rehydration, prevent yarn Good effect of thread damage and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

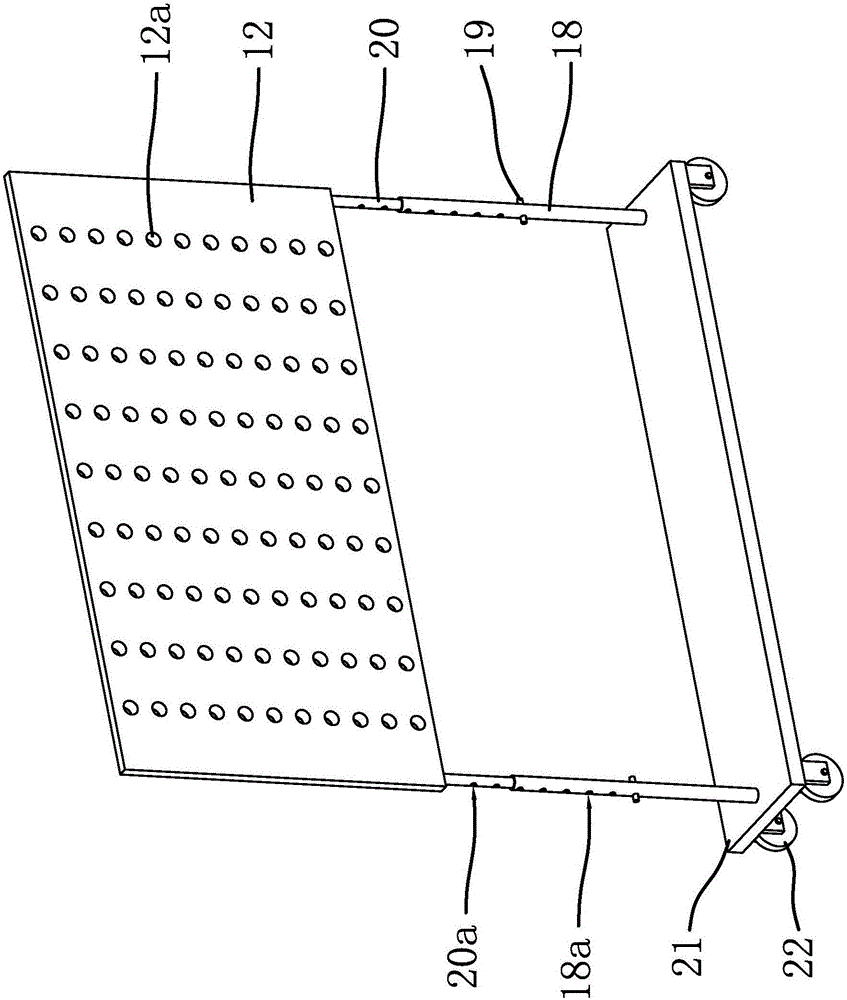

[0051] Such as figure 1 As shown, the glass fiber yarn coating equipment with power mechanism includes a frame 1, a creel 14 is arranged on one side of the frame 1, and a winding device is arranged on the other side of the frame 1, and the creel 14 Be fixed with some installation rods 16 for installing the bobbin, in the present embodiment, the quantity of installation rods 16 is fifty; A thread passing device is arranged between the creel 14 and the frame 1, a paint storage tank 47 is provided on the frame 1, and upper rollers 11 and lower rollers 4 that are rotatable and parallel to each other are arranged on the frame 1. , the lower roller 4 is arranged in the paint storage tank 47, the lower roller 4 is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap