Surfactant fracturing fluid system and preparation method thereof

A surfactant and fracturing fluid technology, applied in the field of oilfield fracturing fluid, can solve the problems of poor water solubility and achieve the effects of low formation damage, small skin effect, and strong flowback ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

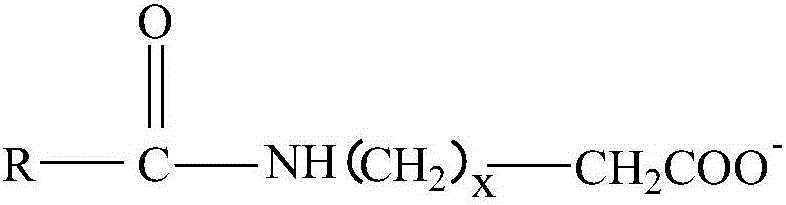

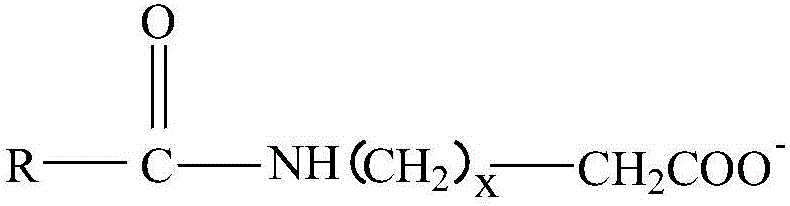

Image

Examples

Embodiment 1

[0019] Dissolve 0.1% fumed silica in water at normal temperature and pressure, and then add 0.15% and 0.3% lauryl amidopropyl dimethyl amine oxide, and stir evenly to obtain a surfactant fracturing fluid.

Embodiment 2

[0021] Dissolve 0.15% fumed silica in water at normal temperature and pressure, and then add 0.2% and 0.4% myristyl amidopropyl dimethyl amine oxide, and stir evenly to obtain a surfactant fracturing fluid.

Embodiment 3

[0023] Dissolve 0.2% fumed silica in water at normal temperature and pressure, and then add 0.3% and 0.5% cetyl amidopropyl dimethyl amine oxide, and stir evenly to obtain a surfactant fracturing fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com