Intelligent decomposition industrial sewage treatment system

A technology for industrial sewage and treatment systems, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as low sewage treatment efficiency, large equipment footprint, and poor ozone production capacity. Achieve the effect of reducing oxygen production power consumption, small footprint, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

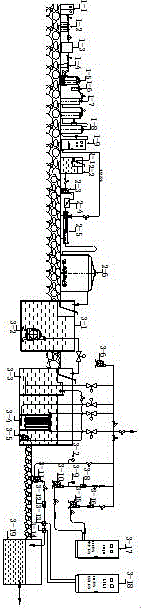

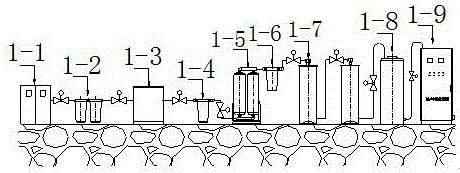

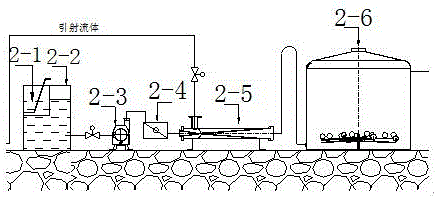

[0022] Such as Figure 1-5 As shown, an intelligent decomposition industrial sewage treatment system includes an auxiliary treatment device, a pretreatment device and a terminal treatment device. The auxiliary treatment device consists of a compressed air station 1-1, an air electrolytic separator 1-3, and a polymer barrier 1- 5. The comprehensive decomposition reactor 1-7, the regulating distributor 1-8 and the PLC central control processor 1-9 are sequentially connected in series, and the pretreatment device includes the sewage temporary storage regulating pool 2-2, and the direct current electrolytic injector 2-5 And the intelligent degradation reaction tower 2-6, the terminal treatment device includes the adjustment pool 3-1 to be treated, the aerobic pool 3-3, the blower 3-6, the MBR membrane bioreactor cleaning management device 3-17, and the terminal treatment management device 3 -18 and discharge temporary storage pool 3-19, a filter device is provided at the entrance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com