Exchange table of fiber laser cutting machine

A fiber laser and switching table technology, applied in the field of switching tables, can solve the problems of low precision, poor work continuity, intermittent interruption of processing work, etc., and achieve the effects of reasonable mechanical structure design, guaranteed cutting quality, and improved synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now the present invention is further described in conjunction with description of drawings and embodiments:

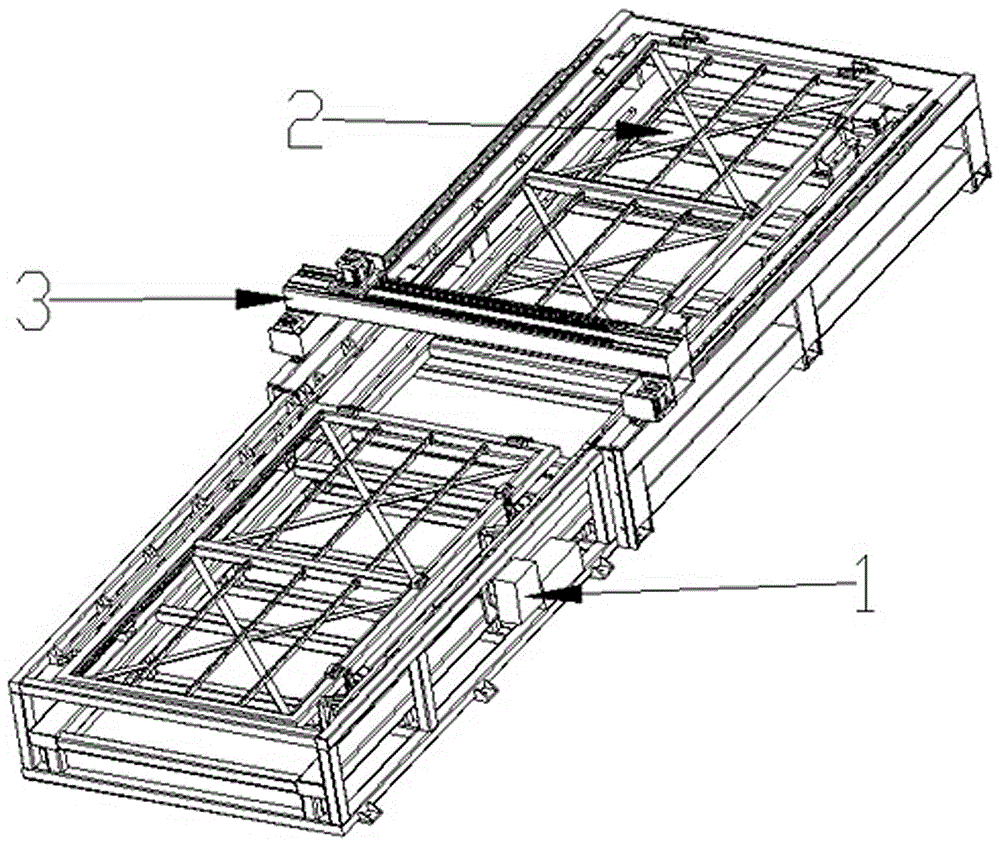

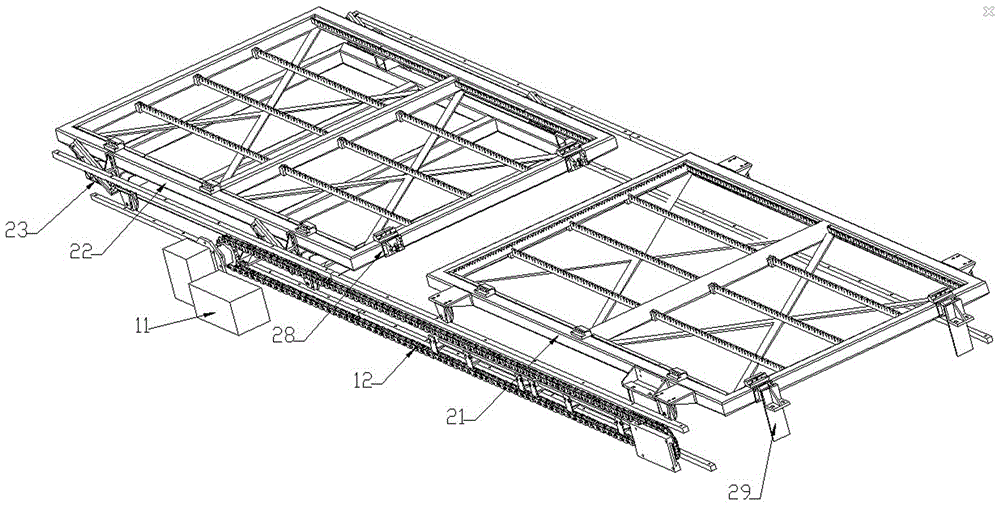

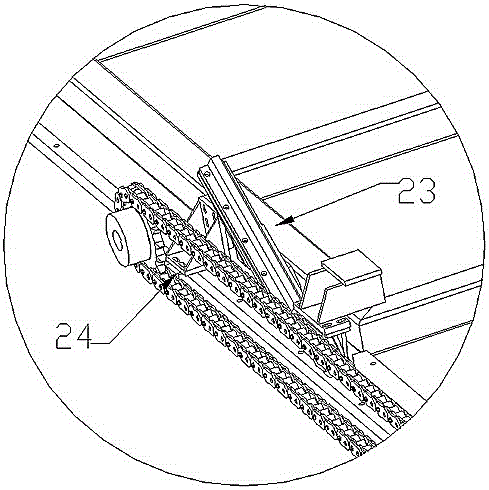

[0019] refer to figure 1 and figure 2 , an exchange platform for a fiber laser cutting machine, including a drive module 1 on the main bed, a workbench 2 and a laser module 3, wherein: the drive module includes a drive motor 11 and a drive chain 12, both of which are arranged on the main bed On one side, the drive chain 12 is divided into an upper chain and a lower chain with two left and right gears as endpoints, and the workbench is staggered left and right and divided into an upper workbench 21 and a lower workbench 22, and the lower workbench 22 is provided with Sliding support frame 23, described and one side of upper workbench 21 and lower workbench 22 are all provided with limit upper pulley 28, one side of described main bed is provided with limit stop 29, and described limit stop 29 limits the limit sliding position of the upper table 21 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com