A wave soldering carrier

A wave soldering and carrier technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve problems such as the inability to meet high-precision component floating requirements, the impact on production efficiency, and the impact on efficiency, and is conducive to automation, reducing Wasteful, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

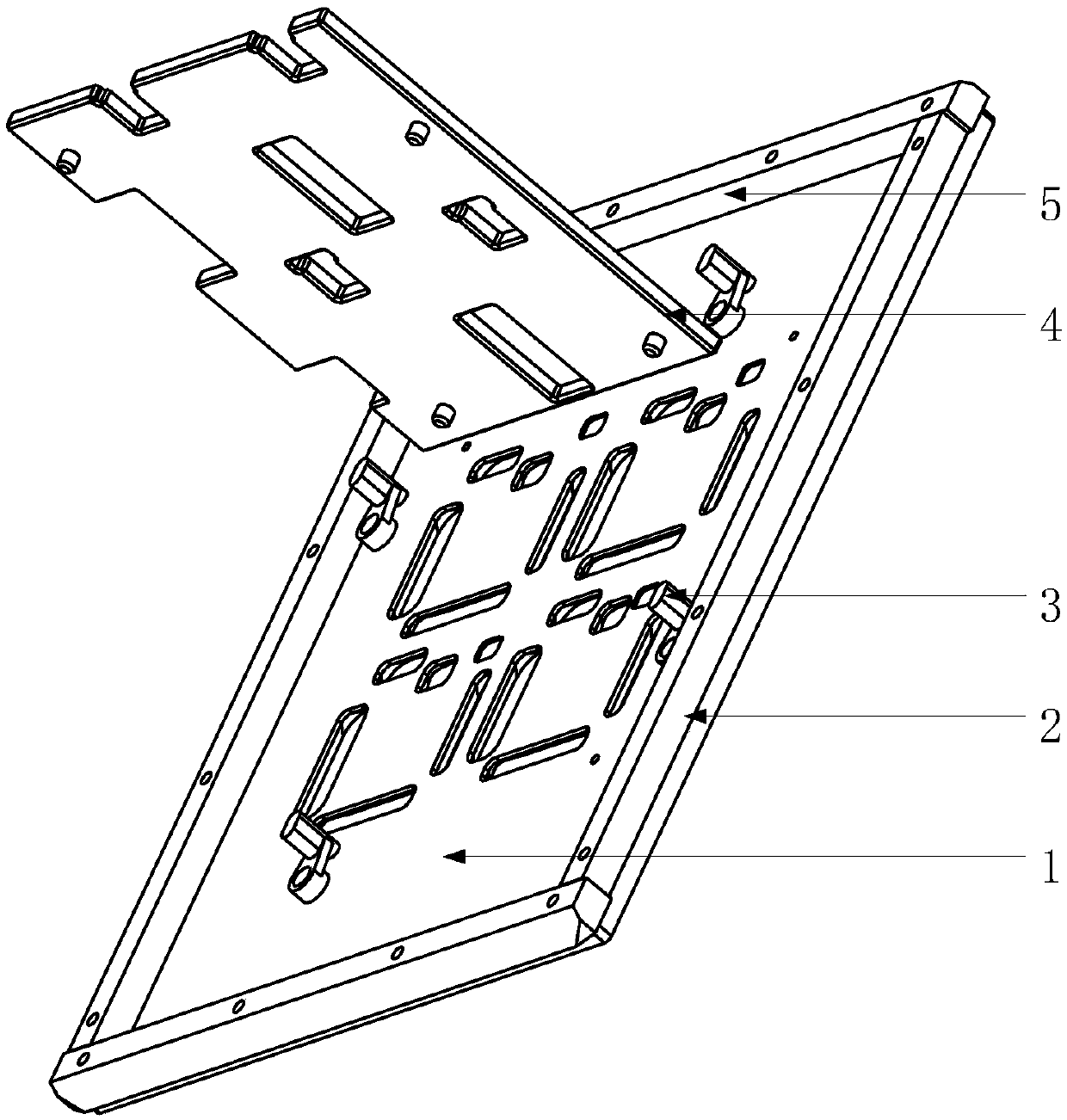

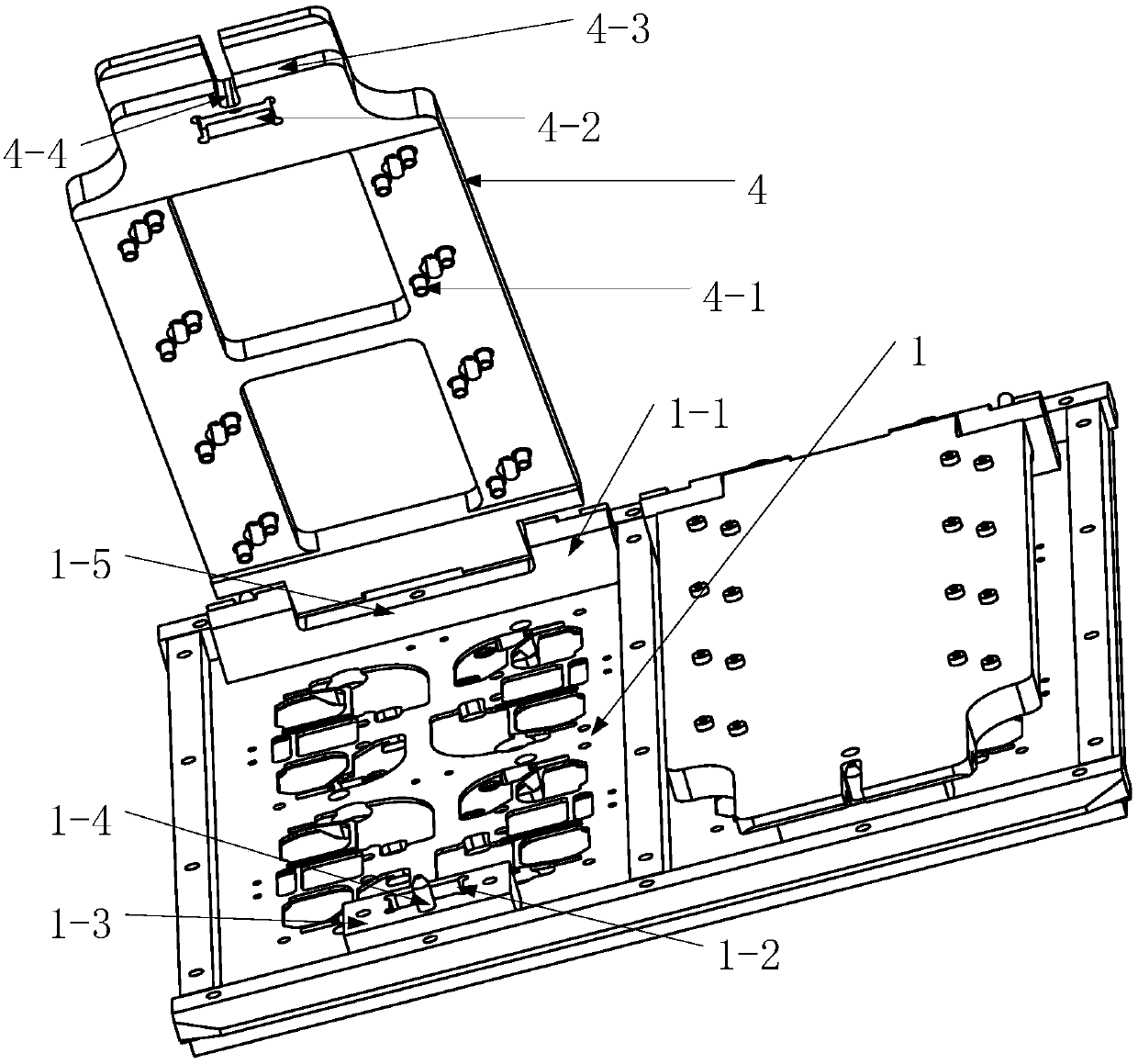

[0022] figure 2 A wave soldering carrier provided for one embodiment of the present invention. Such as figure 2 As shown, a wave soldering carrier includes a bottom plate 1, a pressure plate 4 is arranged on the bottom plate 1, a support block 1-1 is arranged on the bottom plate 1, one end of the pressure plate 4 is hinged with the support block 1-1, and the support block 1-1 limits The pressure plate 4 rotates around the hinge axis within the preset angle range, and when the pressure plate 4 rotates to the open state, the support block 1-1 limits and fixes the pressure plate 4; the side of the pressure plate 4 facing the bottom plate 1 is provided with a corresponding circuit board The spring probe 4-1 of the upper component, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com