Internal clamping type chuck

A chuck and chuck-type technology, which is applied in the field of internal chucks for lathes, can solve the problems of scrapped workpieces and offset of processing parts, and achieve the effects of eliminating adverse effects and improving processing reliability and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

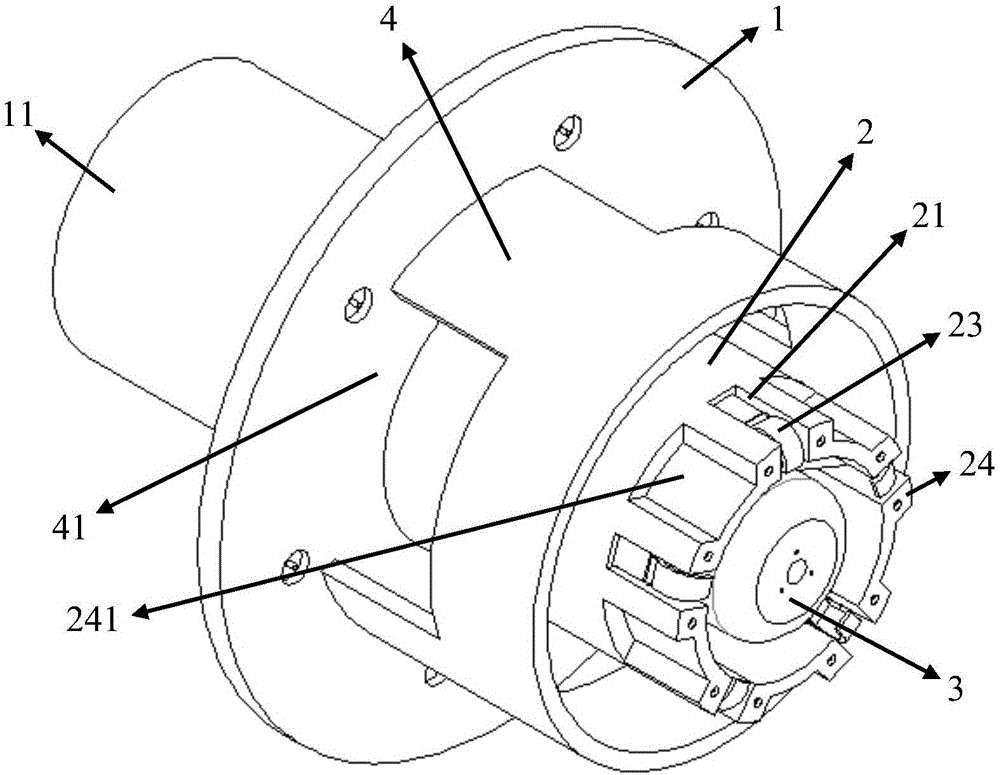

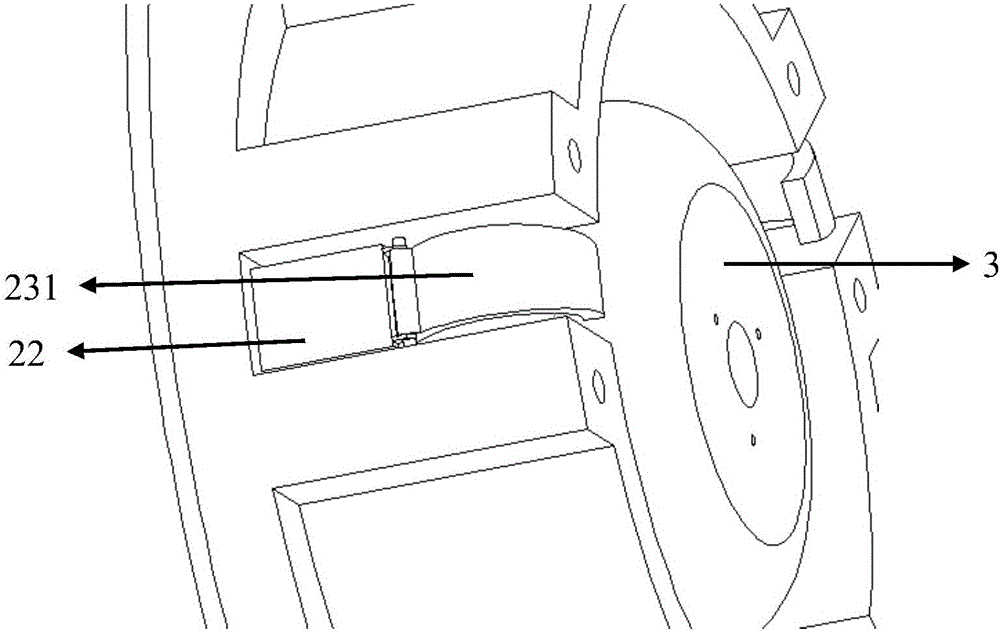

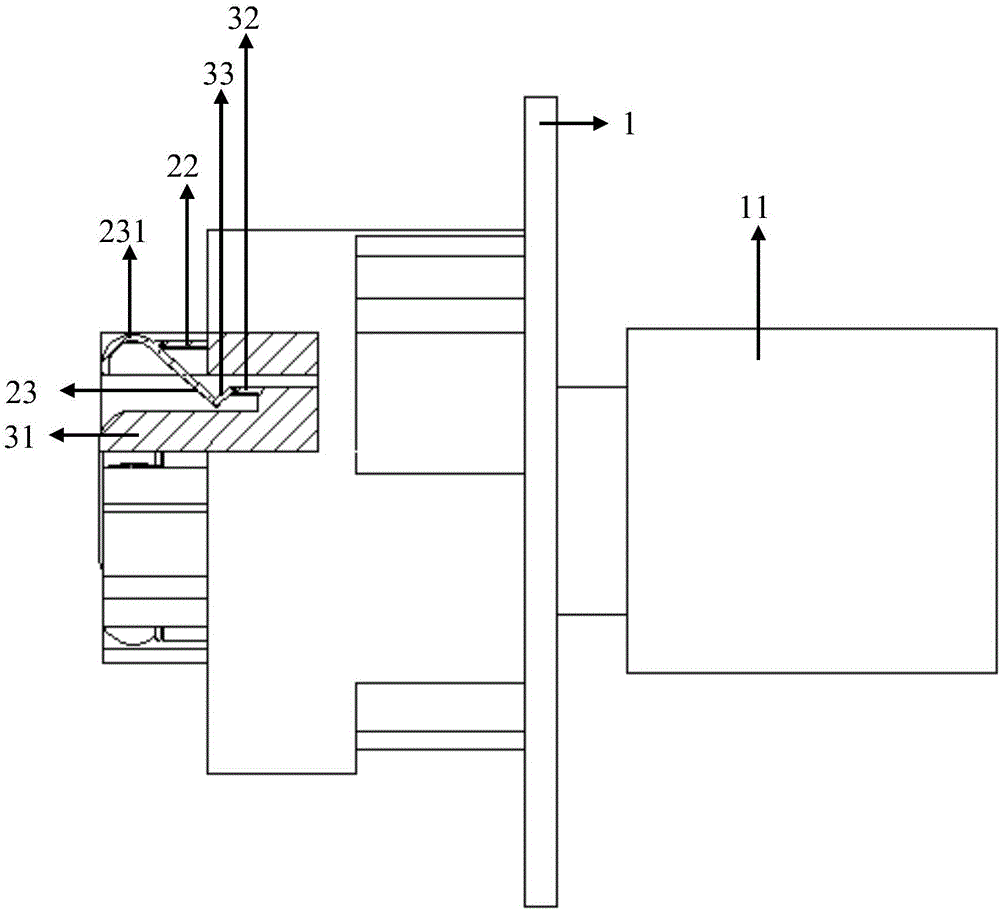

[0017] One embodiment of the structure of the present invention is as Figure 1-3 As shown, it includes a fixed chassis 1 and a clip seat 2 coaxially fixedly connected with it. The end of the clip seat 2 is provided with a number of grooves 21 extending inward along the side wall, and a support wall 22 is provided in the groove 21. , the top of the support wall 22 is hinged with the outer wall of a movable rod 23 near the head 231, the center of the clamp seat 2 is coaxially provided with a telescopic rod 3, and the center of the head of the telescopic rod 3 is a columnar boss 31. A push arm 32 is provided around the head of the telescopic rod 3, and the push arm 32 is connected to the tail of the movable rod 23 through a connecting buckle 33, and the two ends of the connecting buckle 33 are respectively connected to the push arm 32 and movable bar 23 are hinged. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com