Apparatus for double-position automatically circular milling of crank shaft semi-circle keyway

A technology of automatic circulation and semi-circular keys, which is applied in the field of mechanical processing of mechanical parts, can solve the problems of not being able to adapt to mass production, high labor intensity, and low production efficiency, so as to improve processing reliability and efficiency and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

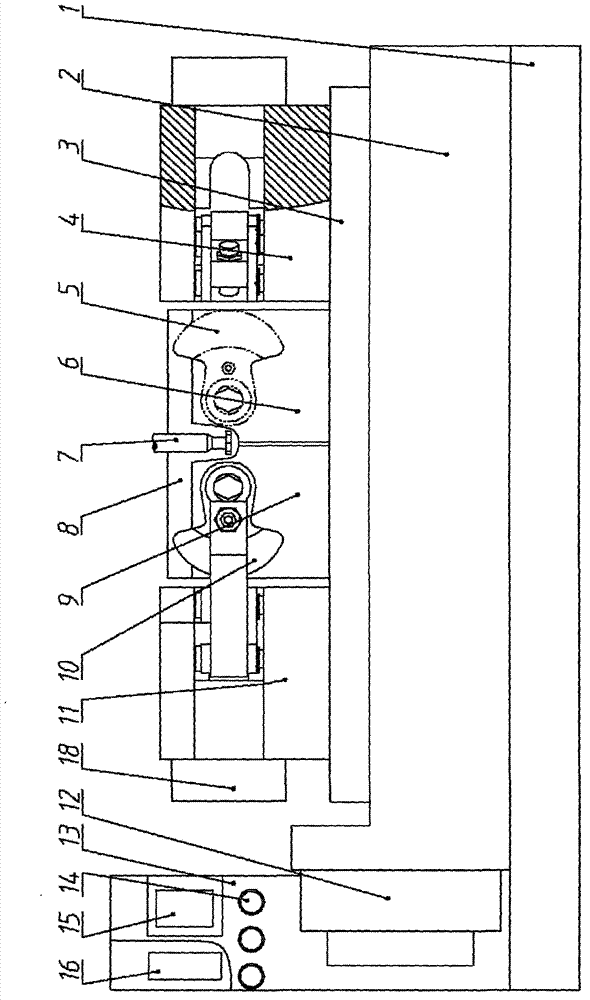

[0015] Such as figure 1 , figure 2 As shown, according to the present invention, a double-station automatic cycle milling crankshaft semicircular keyway device includes a servo slide (servo motor 12, slide body 2, slide body 3), a workpiece positioning mechanism (positioning plate-9 , positioning plate two 6, positioning sleeve one 21, diamond pin one 23, diamond pin two 24, positioning sleeve two 26), pneumatic compression mechanism (tightening cylinder two 27, pin shaft two 31, adjusting screw two 33, connecting rod Two 34, pressure plate two 32, compression cylinder one 20, adjustment screw one 36, pressure plate one 37, pin shaft one 39, connecting rod one 40), pneumatic locking mechanism (locking block two 28, locking cylinder two 29, Locking connection block two 30, locking cylinder one 18, locking block one 19, locking connection block one 41), pneumatic ejection mechanism (fixed plate 8, ejection cylinder one 22, ejection cylinder two 25, ejection Plunger two 35, ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com