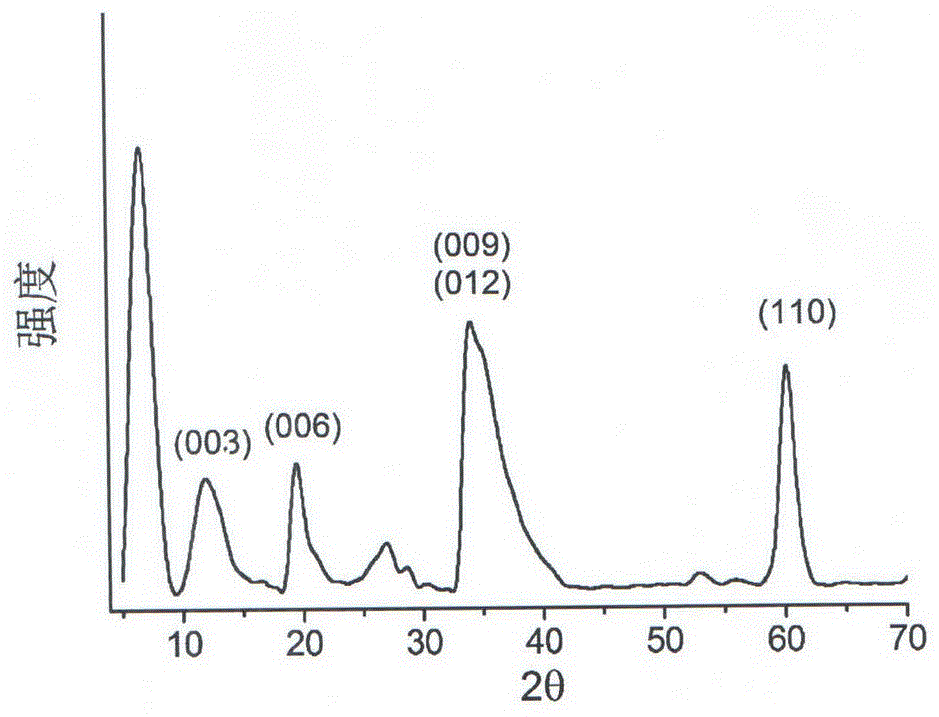

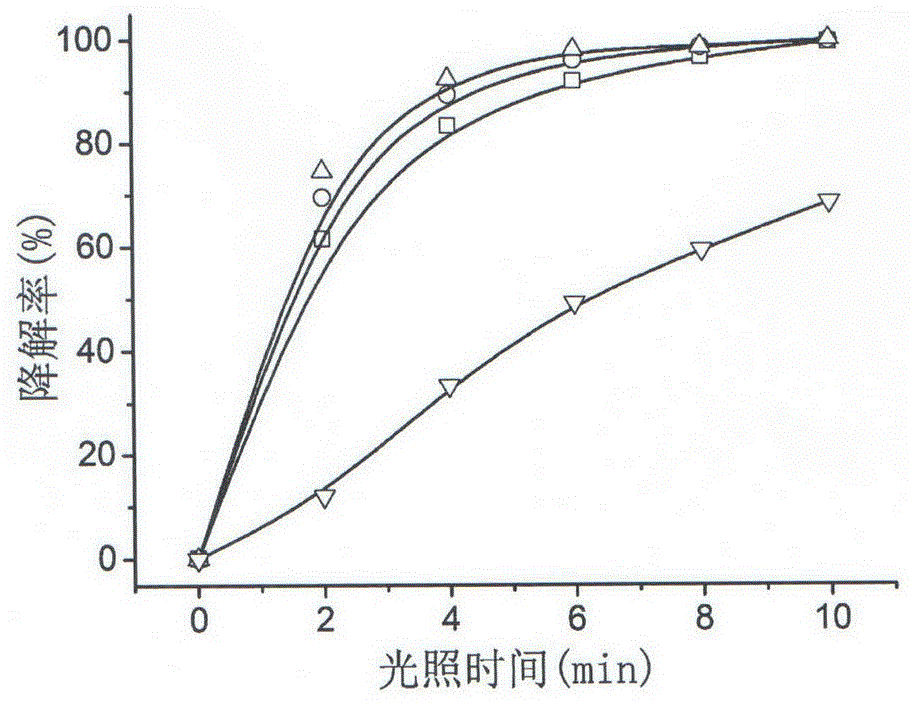

Preparation method and application of flaky zinc-silicon layered double hydroxides photocatalyst

A composite hydroxide, layered double hydroxyl technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the unseen 4-chlorophenol related Reports and other issues, to achieve the effect of rich reserves, small thickness, and increased reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

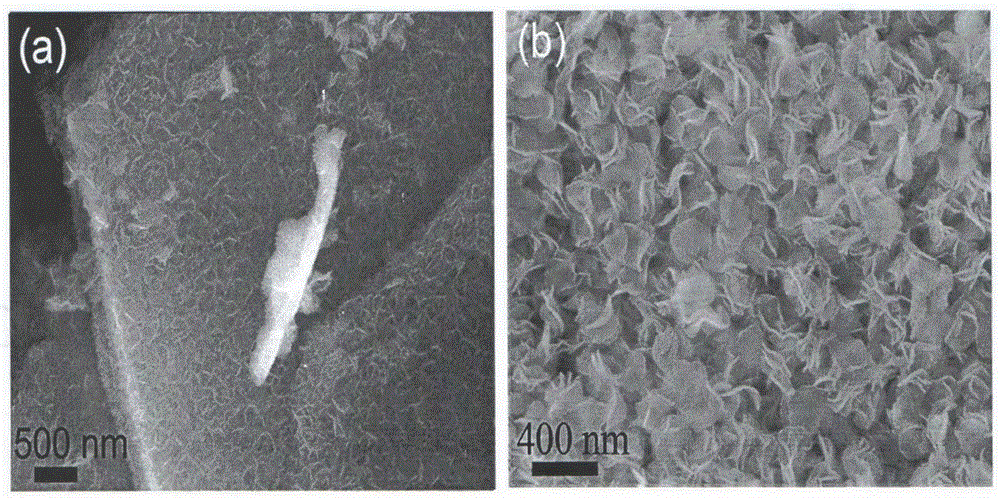

[0024] a. Pass the vermiculite through a sieve of 200 meshes, add 20% by mass to a 2mol / L nitric acid solution, react for 24 hours at a temperature of 40℃, filter, wash with water to neutral, and dry at a temperature of 60℃12 After hours, the silicon dioxide nanosheets are obtained after grinding. The silicon dioxide nanosheets have a lamellar structure rich in silicon hydroxyl groups on the surface. 2 The content is 80%;

[0025] b. Disperse the silicon dioxide nanosheets in step a in 500 mL of deionized water, add hexamethylenetetramine, and stir evenly to obtain an alkaline solution;

[0026] c. Add zinc nitrate to the alkaline solution containing silicon dioxide in step b, Zn 2+ The ratio to the silicon dioxide nanosheets is 10mmol / g. The mixture is stirred at a temperature of 10°C for 10 minutes and then transferred to a reactor, where it is hydrothermally reacted at a temperature of 150°C for 12 hours. The growth method of the nanocrystalline particles is ZnSi -LDH nanocrysta...

Embodiment 2

[0031] a. Pass the vermiculite through a sieve of 300 mesh, add 10% by mass to a 1mol / L hydrochloric acid solution, react at a temperature of 50℃ for 4 hours, filter, wash with water to neutrality, and dry at a temperature of 70℃ for 10 After hours, the silicon dioxide nanosheets are obtained after grinding. The silicon dioxide nanosheets have a lamellar structure rich in silicon hydroxyl groups on the surface. 2 The content is 85%;

[0032] b. Disperse the silicon dioxide nanosheets in step a in 300 mL of deionized water, add sodium hydroxide, and stir evenly to obtain an alkaline solution;

[0033] c. Add zinc chloride to the alkali solution containing silicon dioxide in step b, Zn 2+ The ratio to the silica nanosheets is 15mmol / g. The mixture is stirred at a temperature of 5°C for 20 minutes and then transferred to the reactor, where it is hydrothermally reacted at a temperature of 180°C for 6 hours. The growth method of nanocrystals is ZnSi -LDH nanocrystalline grains are conti...

Embodiment 3

[0037] a. Pass the vermiculite through a sieve of 400 mesh, add 30% by mass to a 3mol / L sulfuric acid solution, react at a temperature of 60°C for 8 hours, filter, wash with water to neutral, and dry at a temperature of 120°C 4 After hours, the silicon dioxide nanosheets are obtained after grinding. The silicon dioxide nanosheets have a lamellar structure rich in silicon hydroxyl groups on the surface. 2 The content is 95%;

[0038] b. Disperse the silicon dioxide nanosheets in step a in 200 mL of deionized water, add tetramethylammonium hydroxide, and stir evenly to obtain an alkaline solution;

[0039] c. Add zinc sulfate to the alkaline solution containing silicon dioxide in step b, Zn 2+ The ratio to the silica nanosheets is 20mmol / g. The mixture is stirred at a temperature of 25°C for 60 minutes and then transferred to a reactor, where it is hydrothermally reacted at a temperature of 120°C for 50 hours. The growth method of nanocrystals is ZnSi -LDH nanocrystalline grains are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com