Scale inhibitor of reverse osmosis membranes

A technology of reverse osmosis membrane and scale inhibitor, which is applied in the field of reverse osmosis membrane scale inhibitor, can solve the problems of general effect, high cost and large usage of scale inhibitor, so as to reduce the hidden danger of biological pollution and bacteria exceeding the standard, and achieve satisfactory results. The effect of comprehensive detergency performance and improved use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

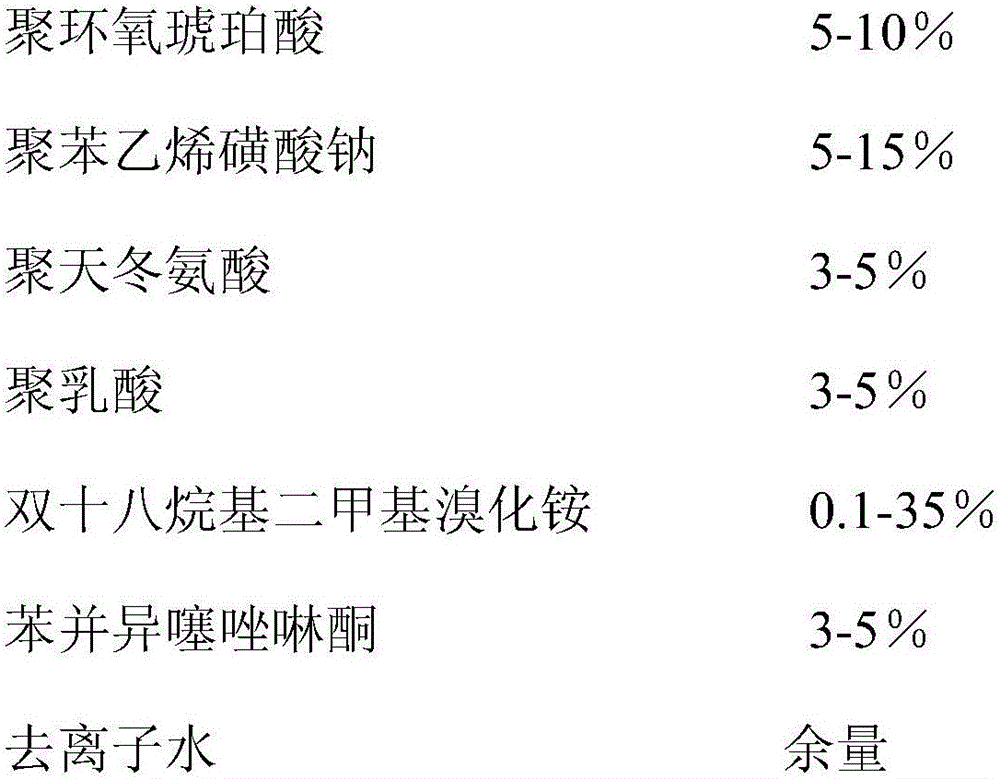

[0016] Embodiment 1: a kind of antiscalant of reverse osmosis membrane, described antiscalant contains following components:

[0017]

[0018] Wherein, the polylactic acid has a molecular weight of 8000, and the polyaspartic acid has a molecular weight of 4500.

[0019] A preparation method of a reverse osmosis membrane antiscalant, comprising the steps of: 2 / 3 deionized water, polyepoxysuccinic acid, sodium polystyrene sulfonate, polyaspartic acid, polylactic acid, benziso Add thiazolinone, dioctadecyldimethylammonium bromide and the remaining deionized water in sequence and corresponding proportions into the container at room temperature, and stir until a uniform transparent solution is obtained, which is the reverse osmosis membrane scale inhibitor.

Embodiment 2

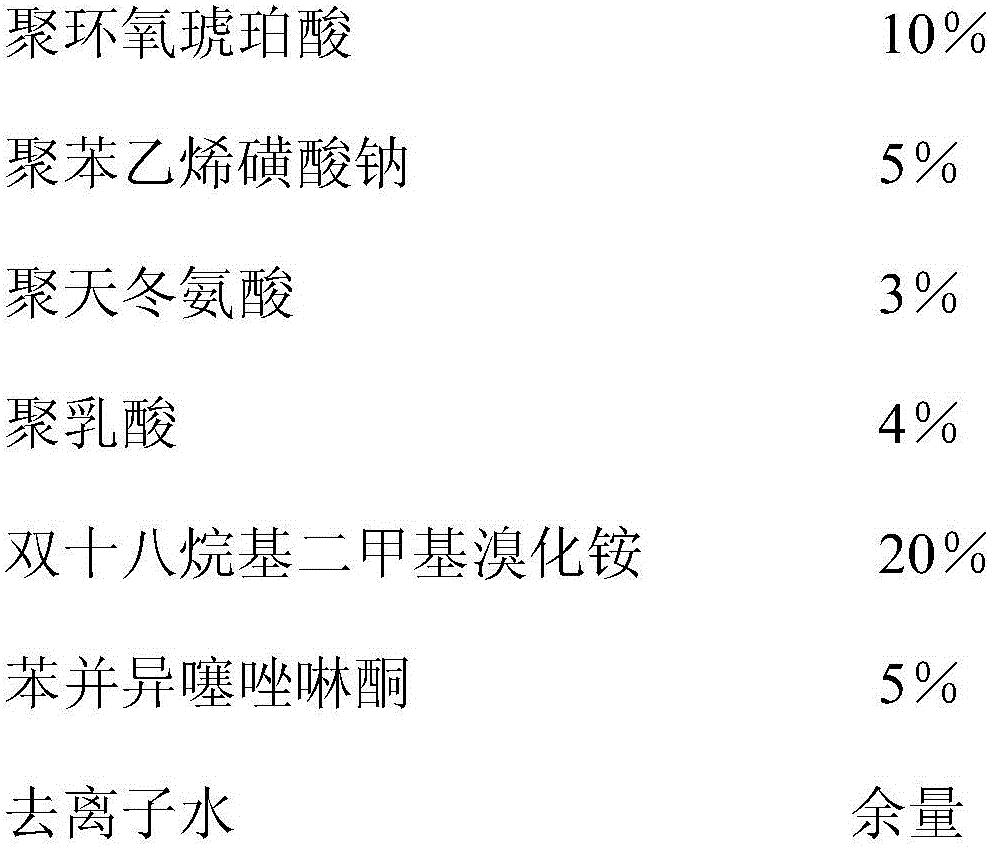

[0020] Embodiment 2: a kind of antiscalant of reverse osmosis membrane, described antiscalant contains following components:

[0021]

[0022] Wherein, the polylactic acid has a molecular weight of 10,000, and the polyaspartic acid has a molecular weight of 5,000.

[0023] A preparation method of a reverse osmosis membrane antiscalant, comprising the steps of: 2 / 3 deionized water, polyepoxysuccinic acid, sodium polystyrene sulfonate, polyaspartic acid, polylactic acid, benziso Add thiazolinone, dioctadecyldimethylammonium bromide and the remaining deionized water in sequence and corresponding proportions into the container at room temperature, and stir until a uniform transparent solution is obtained, which is the reverse osmosis membrane scale inhibitor.

Embodiment 3

[0024] Embodiment 3: a kind of antiscalant of reverse osmosis membrane, described antiscalant contains following components:

[0025]

[0026] Wherein, the molecular weight of polylactic acid is 3000, and the molecular weight of polyaspartic acid is 4000.

[0027] A preparation method of a reverse osmosis membrane antiscalant, comprising the steps of: 2 / 3 deionized water, polyepoxysuccinic acid, sodium polystyrene sulfonate, polyaspartic acid, polylactic acid, benziso Add thiazolinone, dioctadecyldimethylammonium bromide and the remaining deionized water in sequence and corresponding proportions into the container at room temperature, and stir until a uniform transparent solution is obtained, which is the reverse osmosis membrane scale inhibitor.

[0028] The invention provides a reverse osmosis membrane phosphorus-free scale inhibitor that can efficiently remove inorganic scale and colloidal scale deposited on the reverse osmosis membrane. The synergistic effect between r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com