Method for Removing Sulfate from Wastewater

A sulfate and waste water technology, applied in calcium/strontium/barium sulfate, mining waste water treatment, energy waste water treatment, etc., can solve problems such as the influence of parameters not provided, and achieve low sulfate removal rate and reduced sulfate content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

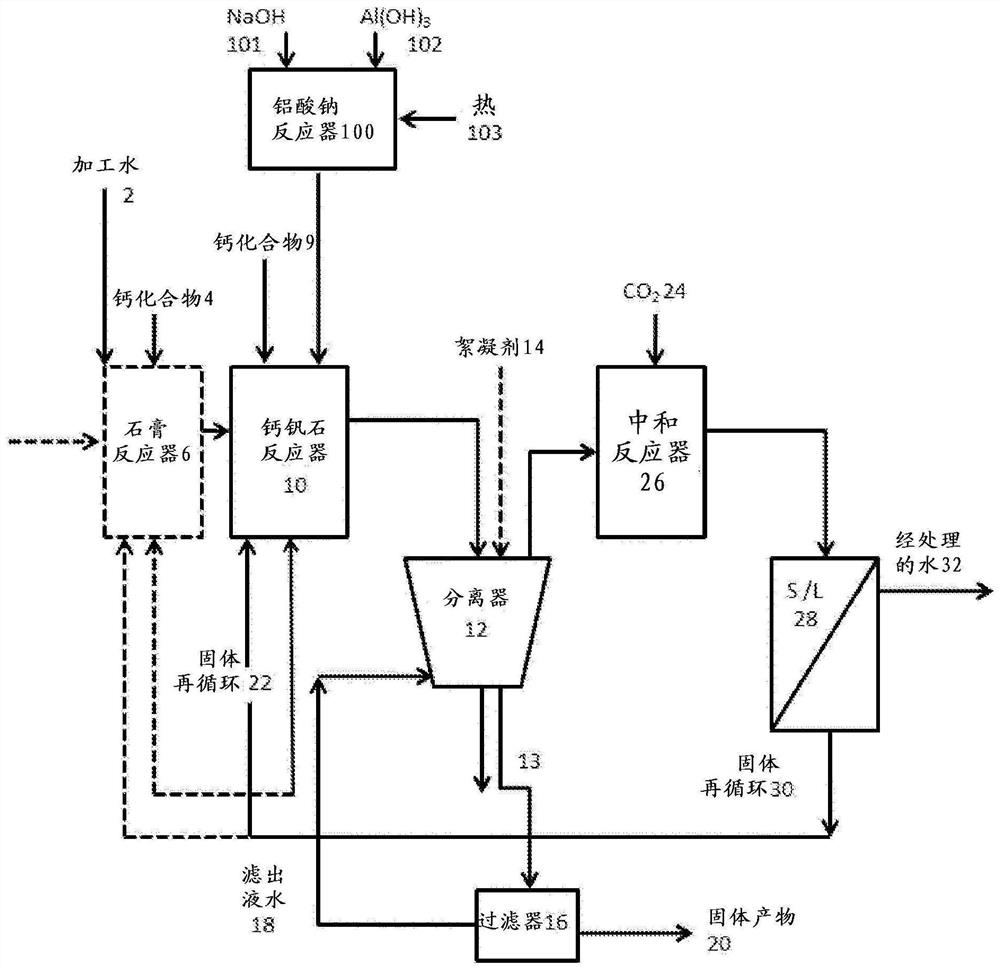

[0072] According to one embodiment of the invention, the plant comprises means for carrying out the above-mentioned method steps.

[0073] According to one embodiment of the invention, the plant comprises a storage tank for storing the sodium aluminate before it is used in the wollastonite precipitation unit.

[0074] According to one embodiment of the invention, the plant comprises a gypsum precipitation unit a') preceding the calcium vanadite precipitation unit b) for precipitating gypsum by contacting waste water with a second calcium compound.

[0075] According to one embodiment of the invention, the plant comprises an optional gypsum removal unit a') between the gypsum precipitation unit a') and the wollastonite precipitation unit b). The gypsum removal unit is used for solid-liquid separation , to remove the precipitated gypsum from the slurry. Typically the gypsum removal unit is a clarifier. A flocculant is typically used to help the sediment settle in the clarifier. ...

Embodiment

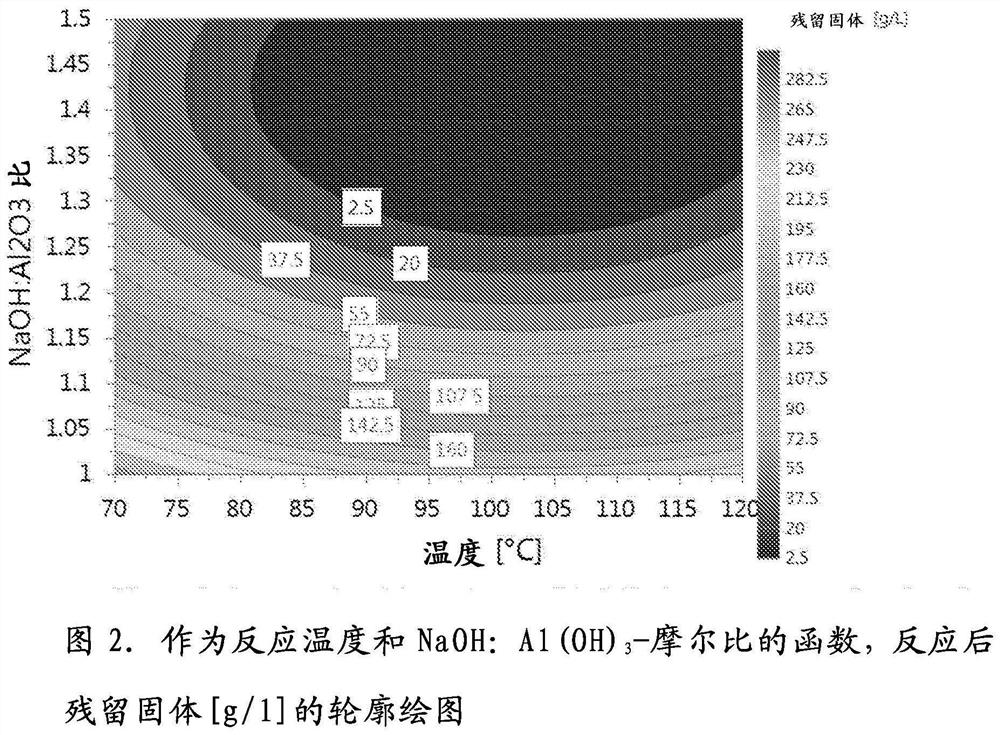

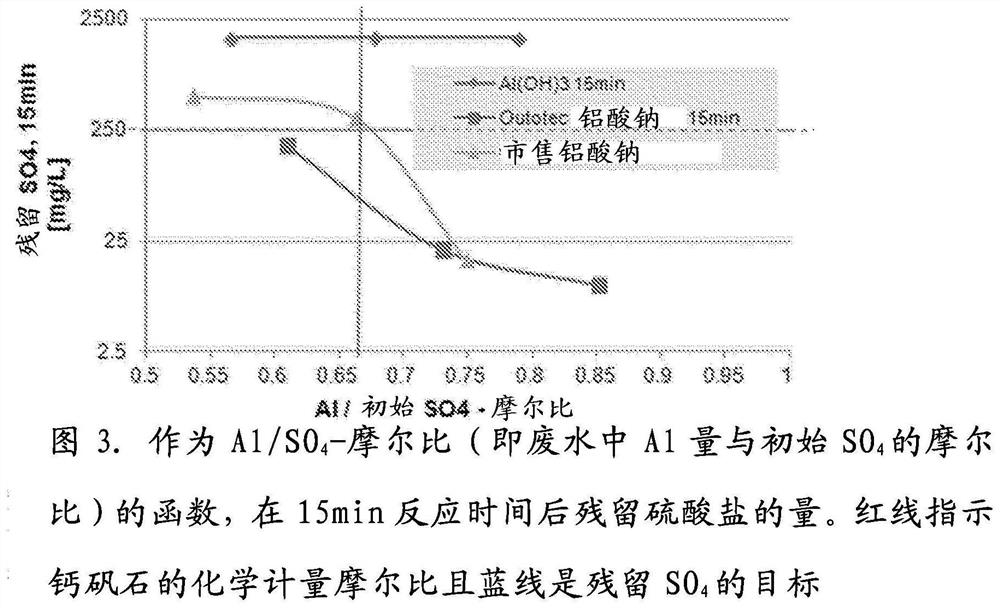

[0106] Experiments for the preparation of sodium aluminate

[0107] An experimental set was carried out to investigate the preparation of sodium aluminate. Change two main variables: molar ratio NaOH:Al(OH) 3 (1-1.5, where >1 indicates a ratio exceeding the stoichiometric ratio) and reaction temperature (70-120°C). Due to the high boiling point of the sodium hydroxide solution, experiments can be performed at atmospheric pressure.

[0108] Table 1. Experimental setup

[0109] Na / Al-molar ratio Al(OH) 3 [g]

Reaction temperature [°C] Dilution water [g] EXP1 1.500 495 120 180 EXP2 1.500 495 70 180 EXP3 1.250 592 120 364 EXP4 1.250 592 95 364 EXP5 1.250 592 70 364 EXP6 1.000 740 120 646 EXP7 1.000 740 70 646 EXP8 1.375 540 107 265

[0110] experiment

[0111] Sodium hydroxide (50% solution, technical grade) was first heated up to 50°C. Add Al(OH) 3 .

[0112] After adding Al(OH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com