Structure and preparation method of aluminum liquid-cooled chassis

A technology of liquid cooler and cooler, which is applied in the construction parts of electrical equipment, cooling/ventilation/heating modification, electrical components, etc. It can solve the problems of poor weldability, high processing cost, and solder accumulation, etc., to meet high power requirements. , excellent welding performance, and the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

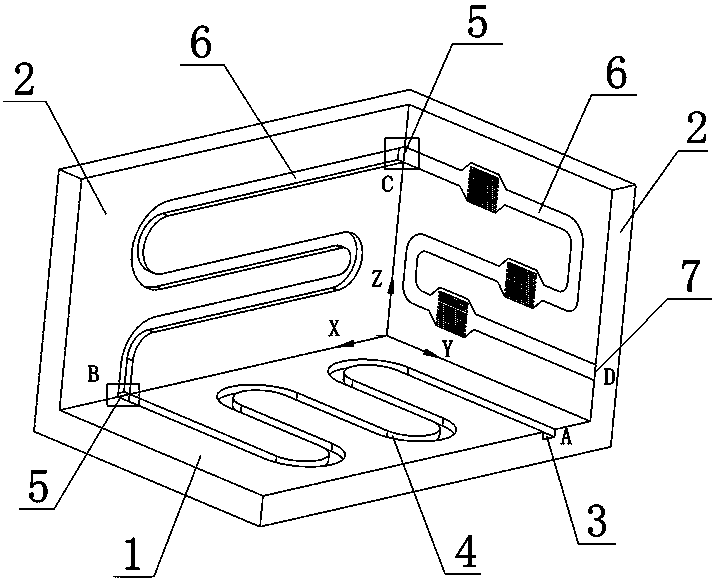

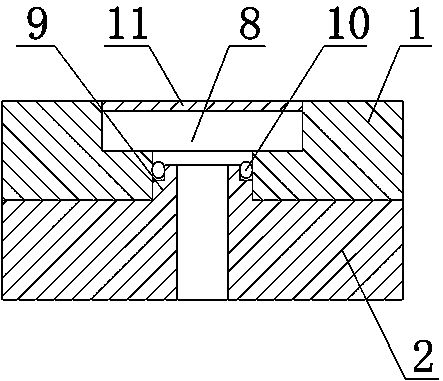

[0025] A method for preparing an aluminum liquid-cooled chassis structure, comprising the following steps:

[0026] S1. Processing of cooling plate parts: According to the final structural size and welding allowance of cooling bottom plate 1 and cooling wall plate 2, determine the processing content of the parts, and shape them through mechanical processing. The flatness of the welding surface is less than 0.3mm, and the roughness level of the welding surface Higher than Ra1.6, the machining allowance of the cooling plate after welding is 3mm on one side;

[0027] S2. Cooling plate welding process: the cooling bottom plate 1 and the cooling wall plate 2 are respectively chemically cleaned to remove the surface oxide film, and a protective agent is used to prevent the secondary oxidation of the workpiece, and they are formed by vacuum diffusion welding. The welding temperature is 560 ° C. The pressure is 5MPa, and the sealing of the cooling plate flow channel is tested after we...

Embodiment 2

[0032] A method for preparing an aluminum liquid-cooled chassis structure, comprising the following steps:

[0033] S1. Processing of cooling plate parts: According to the final structural size and welding allowance of cooling bottom plate 1 and cooling wall plate 2, determine the processing content of the parts, and shape them through mechanical processing. The flatness of the welding surface is less than 0.3mm, and the roughness level of the welding surface Higher than Ra1.6, the machining allowance of cooling plate after welding is 2.5mm on one side;

[0034] S2. Cooling plate welding process: chemically clean the cooling bottom plate 1 and the cooling wall plate 2 to remove the surface oxide film, and use a protective agent to prevent the secondary oxidation of the workpiece. They are formed by vacuum diffusion welding. The welding temperature is 555°C. The pressure is 4MPa, and the sealing of the cooling plate flow channel is tested after welding;

[0035] S3. Secondary ...

Embodiment 3

[0039] A method for preparing an aluminum liquid-cooled chassis structure, comprising the following steps:

[0040]S1. Processing of cooling plate parts: According to the final structural size and welding allowance of cooling bottom plate 1 and cooling wall plate 2, determine the processing content of the parts, and shape them through mechanical processing. The flatness of the welding surface is less than 0.3mm, and the roughness level of the welding surface Higher than Ra1.6, the machining allowance of the cooling plate after welding is 2mm on one side;

[0041] S2. Cooling plate welding process: chemically clean the cooling bottom plate 1 and the cooling wall plate 2 to remove the surface oxide film, and use a protective agent to prevent the secondary oxidation of the workpiece. They are formed by vacuum diffusion welding. The welding temperature is 550°C. The pressure is 2MPa, and the sealing of the cooling plate flow channel is tested after welding;

[0042] S3. Secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com