Puncture wire clamp

A technology for piercing wire clamps and clips, which is applied in the direction of clamping/spring connection, needle point/slotted plate contact parts and electrical components used to penetrate insulated wires/cable core wires, and can solve the problem that it is difficult to ensure the contact between the tooth piece and the Power cables are in close contact, anti-corrosion aging, poor firmness and other issues, to achieve the effect of improved sealing, strong current carrying capacity, and balanced grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will give descriptions of specific embodiments in conjunction with the accompanying drawings of the present invention, but not as any limitation to the present invention.

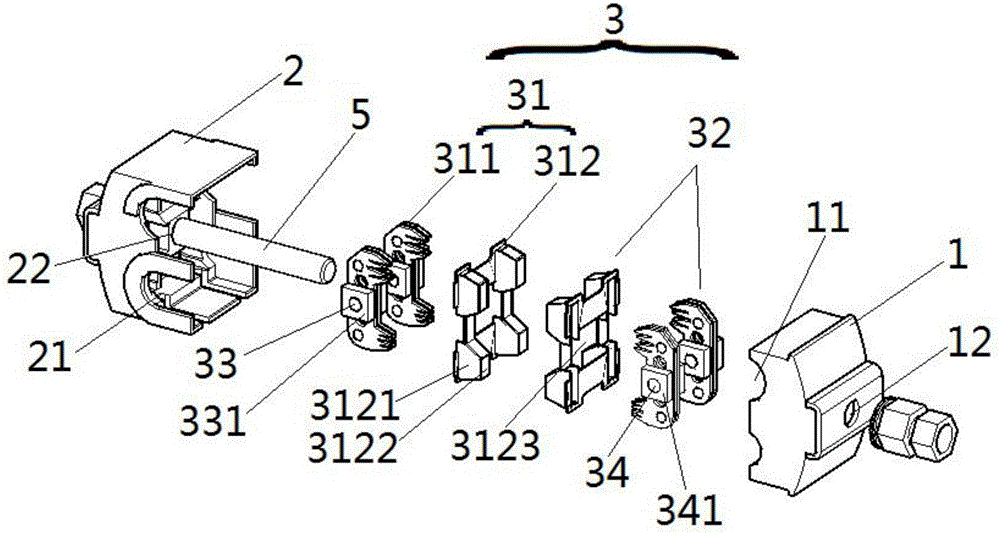

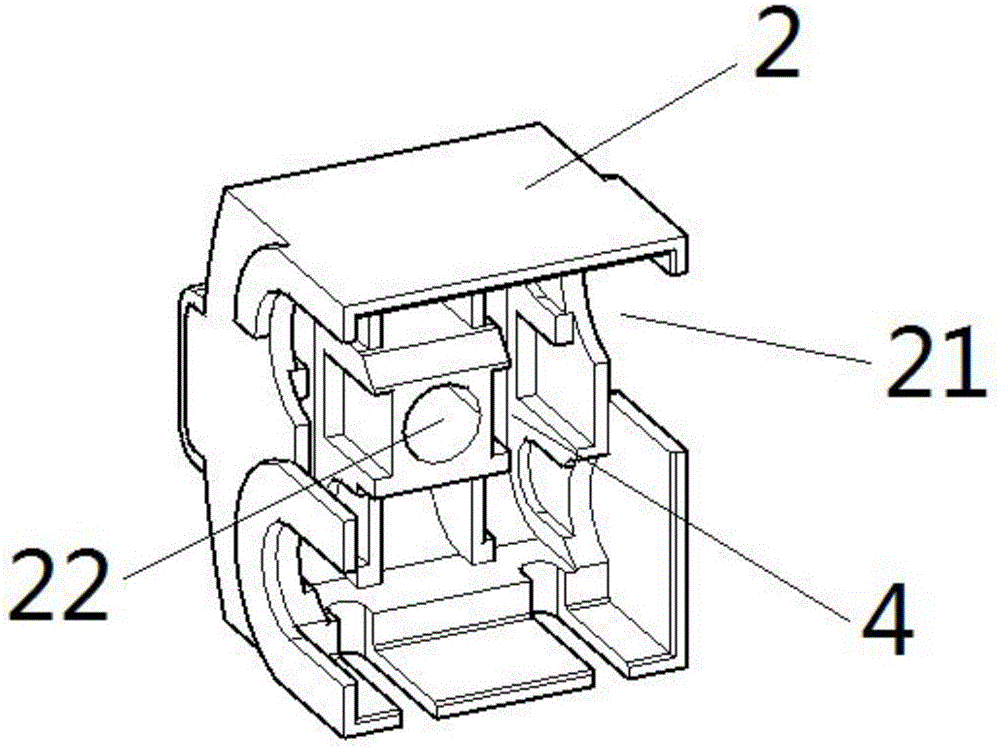

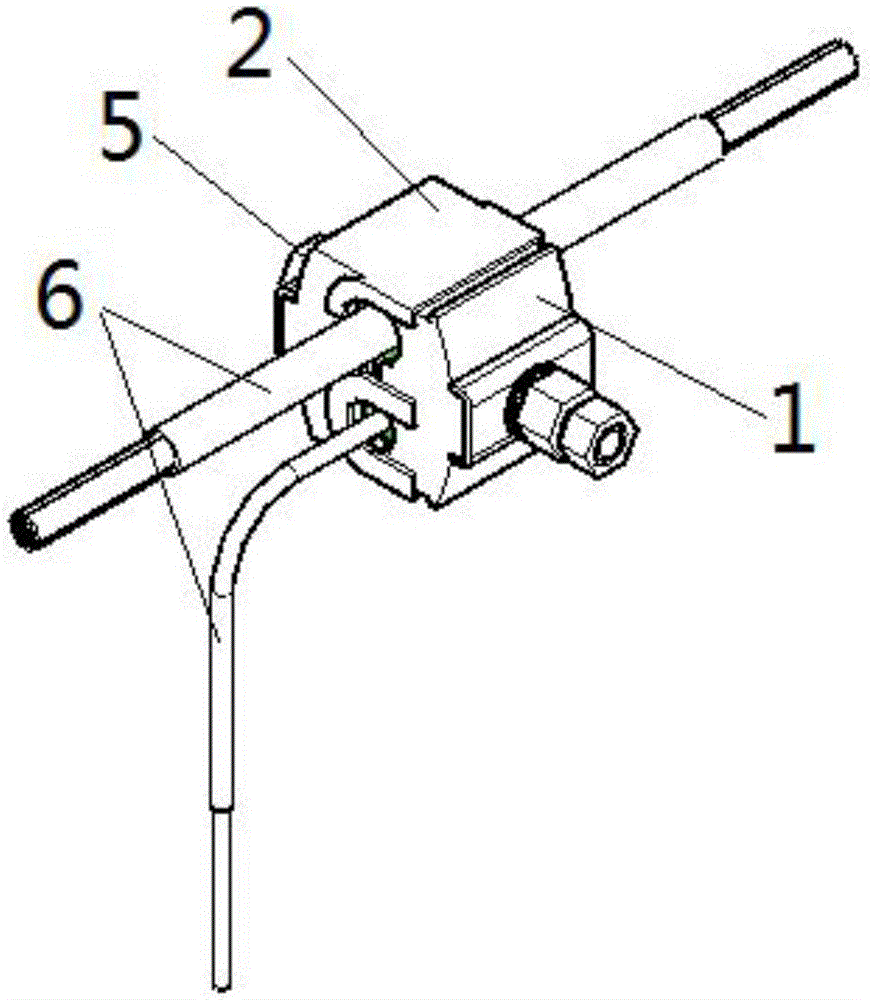

[0031] see figure 1 and figure 2 , a puncture wire clamp, including a front cover 1, a rear cover 2 and a plurality of clamping units 3; the front cover 1 and the rear cover 2 are detachably and fixedly connected, and the side of the front cover 1 facing the rear cover 2 is provided with a first opening Slot 11, the side of the back cover 2 facing the front cover 1 is provided with a second opening slot 21 opposite to the opening of the first opening slot 11, the first opening slot 11 and the second opening slot 21 are buckled to form a clamping power cable Inclusion hole; each clamping unit 3 includes a first clamping part 31 and a second clamping part 32, the first clamping part 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com