A device for manufacturing large-aperture high-pressure high-volume energy storage foil

A technology of energy storage foil and large aperture, which is applied in the manufacture of capacitors, capacitors, capacitor parts, etc., can solve the problems that cannot meet the manufacturing requirements of electrode foils for ultra-high voltage aluminum electrolytic capacitors, and achieve regular apertures, convenient operation, and clean cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

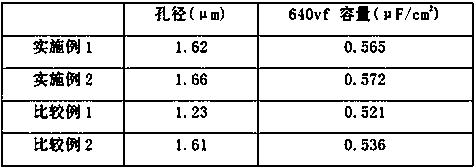

Embodiment 1

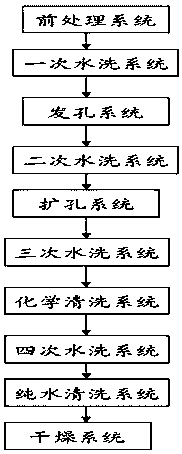

[0024] Such as figure 1 As shown, a device for manufacturing large-aperture high-pressure high-volume energy storage foil, including sequentially connected pretreatment system, primary water washing system, hair hole system, secondary water washing system, hole expansion system, three water washing system, and chemical cleaning system , four-time water washing system, pure water cleaning system and drying system, among which the reaming system is a DC current change type electrochemical corrosion system, the reaming system includes electrolytic cells, two pairs of U-shaped graphene electrode plates, liquid inlet pipes, flow The pretreatment system is an acid treatment system; the hole system is a direct current constant current electrochemical corrosion system; the chemical cleaning system is a nitric acid cleaning system; the primary water washing system and the fourth water washing system are spray pipes Type water washing system; the secondary water washing system and the t...

Embodiment 2

[0038] Such as figure 1 As shown, a device for manufacturing large-aperture high-pressure high-volume energy storage foil, including sequentially connected pretreatment system, primary water washing system, hair hole system, secondary water washing system, hole expansion system, three water washing system, and chemical cleaning system , four-time water washing system, pure water cleaning system and drying system, among which the reaming system is a DC current change type electrochemical corrosion system, the reaming system includes electrolytic cells, two pairs of U-shaped graphene electrode plates, liquid inlet pipes, flow The pretreatment system is an acid treatment system; the hole system is a direct current constant current electrochemical corrosion system; the chemical cleaning system is a nitric acid cleaning system; the primary water washing system and the fourth water washing system are spray pipes Type water washing system; the secondary water washing system and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com