Loop layout of reactor coolant for passive pressurized water reactor nuclear power plant

A technology for pressurized water reactor nuclear power plants and reactors, applied in the directions of reactors, cooling devices, nuclear power plant auxiliary equipment, etc., can solve problems such as the difficulty of main pump development, and achieve the effects of avoiding development problems, improving localization rate, and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

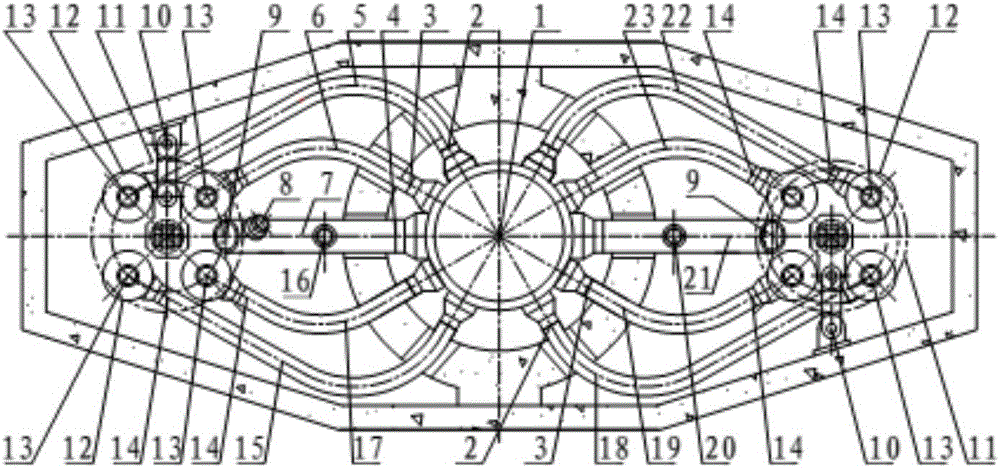

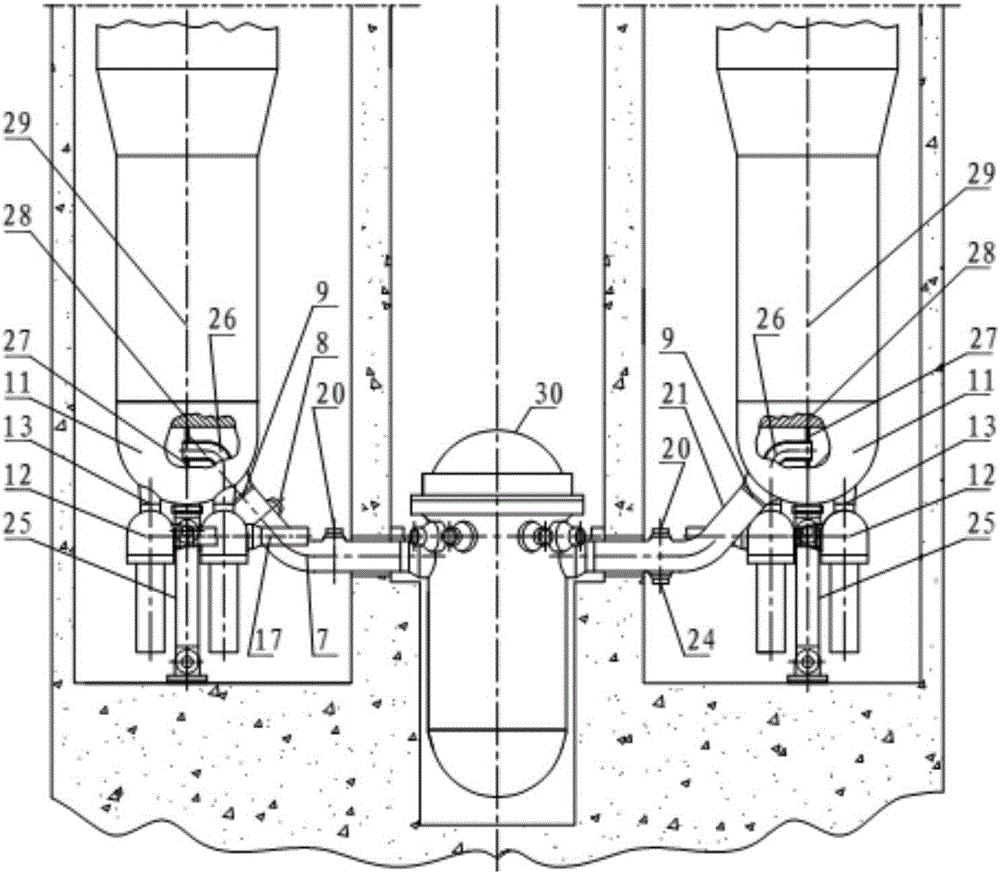

[0044] like figure 1 and 2 As shown, it is the layout of the reactor coolant loop of the passive PWR nuclear power plant, including:

[0045] 1. Reactor pressure vessel:

[0046] Under the condition that the opening of the reactor pressure vessel connecting section cylinder (see item 1) is allowed, two reactor coolant outlet nozzles (see item 4) are arranged on the reactor pressure vessel connecting section cylinder to connect two main pipes The hot section (see item 7 or item 21), and eight reactor coolant inlet nozzles (see item 2 or item 3) are used to connect the cold sections of the eight main pipes (see item 5, item 6, item 15 , Item 17 or see Item 18, Item 19, Item 22, Item 23). Two reactor coolant outlet nozzles are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com