A monitoring and real-time thermal error compensation system of machine tool temperature field based on wsn

A compensation system and thermal error technology, applied in the field of machine tool temperature field monitoring and real-time thermal error compensation system based on WSN, can solve the problems of difficult implementation of online monitoring of the temperature field of the whole machine tool, inconvenient data transmission, etc., and achieve a compact node structure. , The layout is flexible and convenient, and the effect of overcoming the inconvenience of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

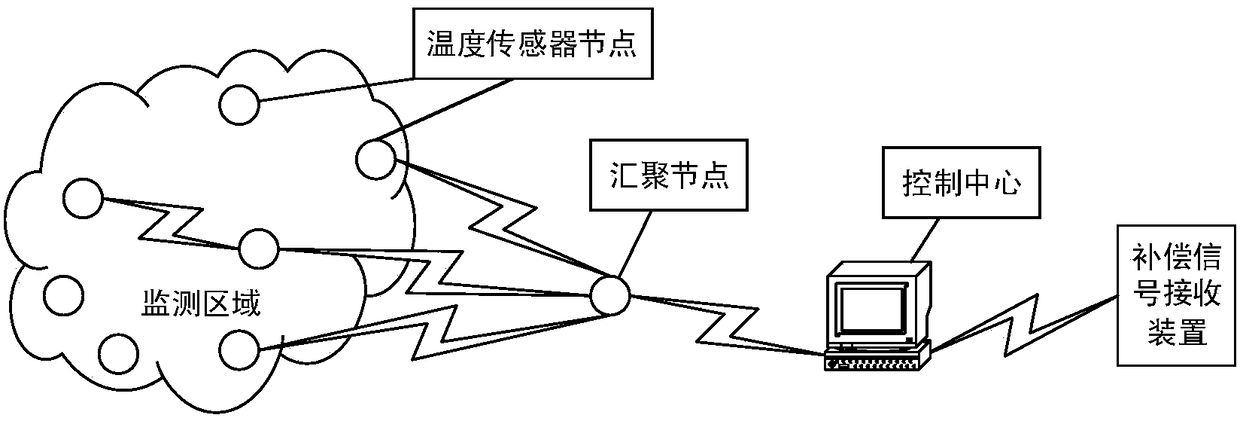

[0031] The machine tool temperature field monitoring and real-time thermal error compensation system proposed by the present invention is realized based on the developed WSN application platform, and its wireless network topology diagram is as follows figure 1 shown.

[0032] The present invention proposes a WSN-based machine tool temperature field monitoring and real-time thermal error compensation system, including a machine tool numerical control system, and also includes a WSN application platform. The WSN application platform includes sequentially connected wireless temperature sensor nodes, convergence nodes, control centers, Compensation signal receiving device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com