Quick boron applying device for boron-coated tank of boron-coated neutron detector and working method thereof

A neutron detector and boron coating technology, applied in the field of nuclear radiation detection, can solve the problems of unstable quality and low efficiency of boron-coated liner, and achieve the effects of convenient operation, improved popularization and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

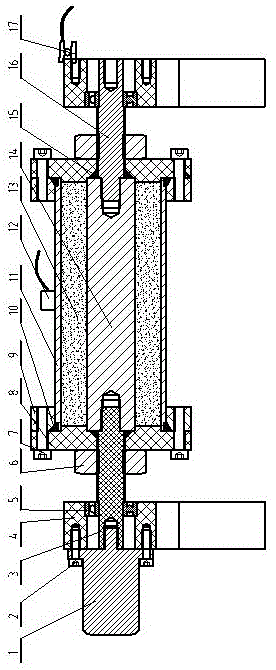

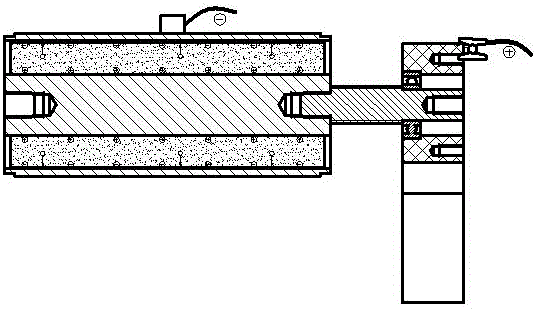

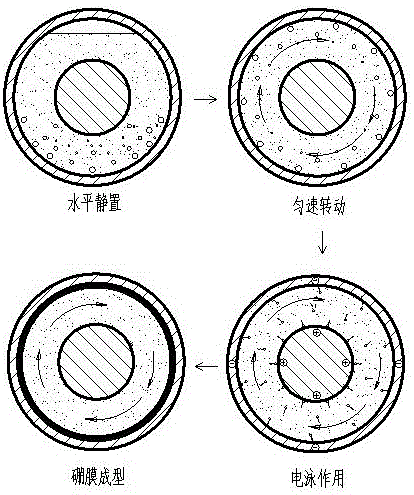

[0028] like figure 1 Shown is an embodiment of the general structure of the present invention. Put the coupling screw 3 on the small sealing ring 15, screw it with the positive electrode core 14, pass through the center hole of the end compression disc 8, and squeeze the end compression disc by screwing with the compression ring 6 8. Form a seal on the inner ring at the left end of the axial direction, and then put the boron-coated liner 11 on the positioning locking ring 9 and the large sealing ring 10 in sequence, coordinate with the end pressure plate 8 for positioning, and squeeze and tighten with the fixed long screw 7. Form the axial left end outer ring seal. Install the output screw 16 on the right end of the positive electrode core 14, rotate the axis to the vertical direction, pour the boron-coated solution 13 into the cavity, put the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com