Wavelet-packet-and-support-vector-machine-based on-line detection method for assembling state of main shaft bearing of machine tool

A support vector machine and bearing assembly technology, which is applied in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as weak reasoning ability, limited fault diagnosis accuracy, and difficult feature extraction, and achieve fast The effect of accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

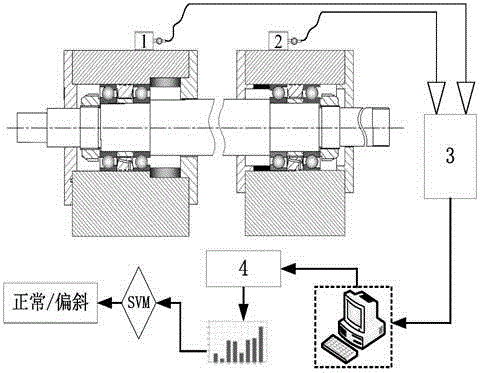

[0045] The present invention is an online detection method for the assembly state of the machine tool spindle bearing based on wavelet packets and support vector machines, which uses a vibration acceleration sensor to collect the vibration signals of the machine tool spindle bearing in the normal operation state and the bearing deflection state;

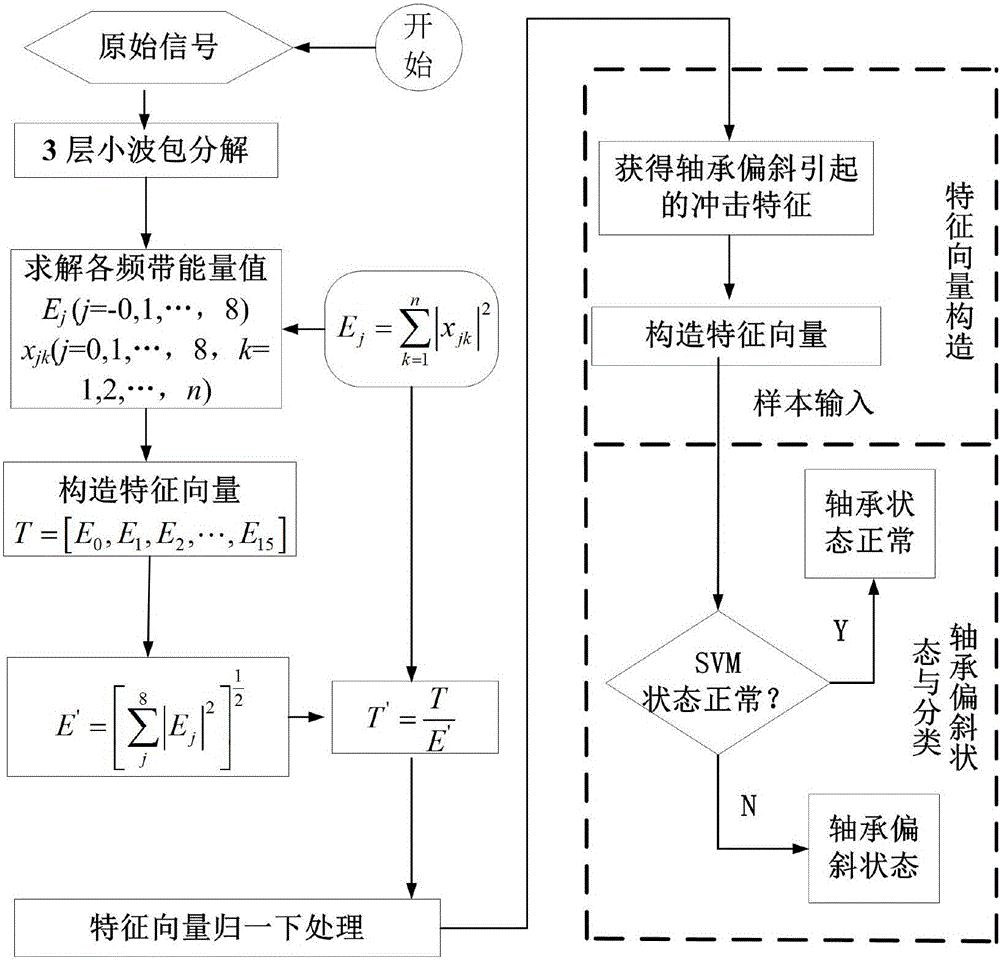

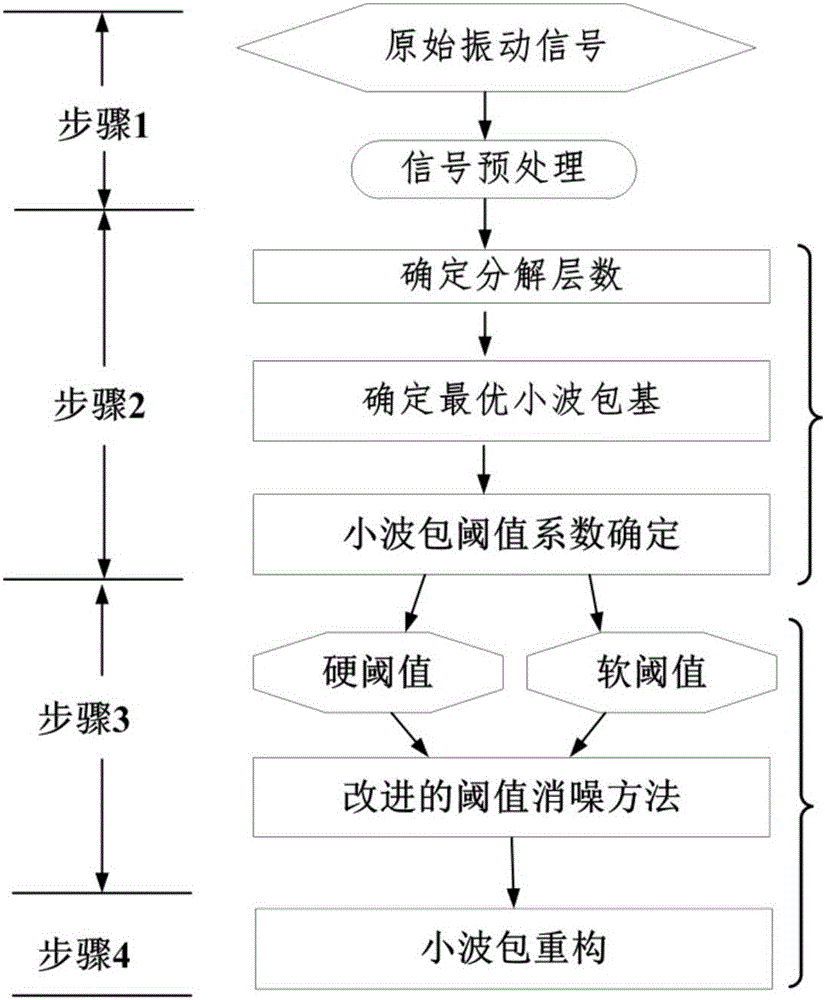

[0046] Using the improved wavelet threshold de-noising method, introducing α factor, the vibration signal is decomposed by wavelet, and the vibration signal is mapped to a set of basis functions formed by wavelet stretching and translation. Separation is carried out at all times to realize denoising processing of vibration signals.

[0047] The wavelet packet reconstruction is performed on the denoised signal, so that the signal energy of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com