Planar two-degree-of-freedom high-frequency loading device and testing platform for ball screw pair

A ball screw pair and loading device technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of low device reliability, difficulty in ensuring loading accuracy, and poor dynamic characteristics. Achieve independent control, ensure loading accuracy, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

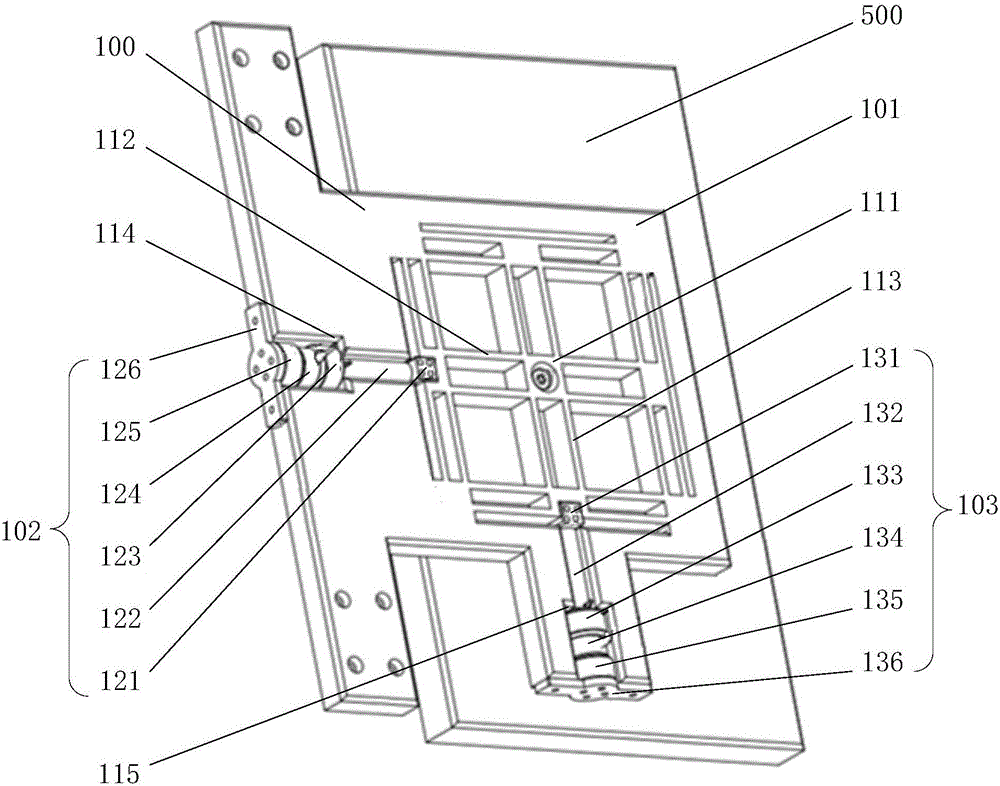

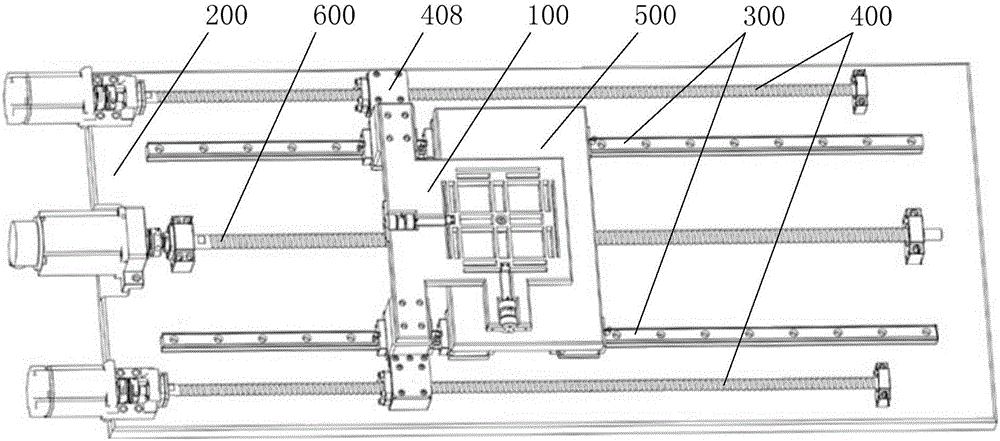

[0018] Such as figure 1 As shown, the present invention provides a planar two-degree-of-freedom high-frequency loading device 100 for a ball screw pair, which includes a flexible hinge parallel mechanism base 101 , a first drive branch chain 102 and a second drive branch chain 103 .

[0019] Wherein, a rigid dynamic platform 111 is set at the center of the base body 101 of the flexible hinge parallel mechanism, and the planar two-degree-of-freedom high-frequency loading device 100 is connected to the workbench 500 of the ball screw linear feed system to be tested through the rigid dynamic platform 111; A first flexible branch chain 112 and a second flexible branch chain 113 are respectively arranged in two vertical directions passing through the center of the rigid moving platform 111, and the first flexible branch chain 112 and the second flexible br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com