A high-precision probe loading device for pcb automatic test equipment

A technology of automatic test equipment and loading device, which is used in measurement devices, electronic circuit testing, printed circuit testing, etc., can solve the problems of small probe pressure adjustment range, complex mechanical structure, low loading accuracy, etc., and achieve reasonable and reliable structural design. , to prevent probe damage, the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

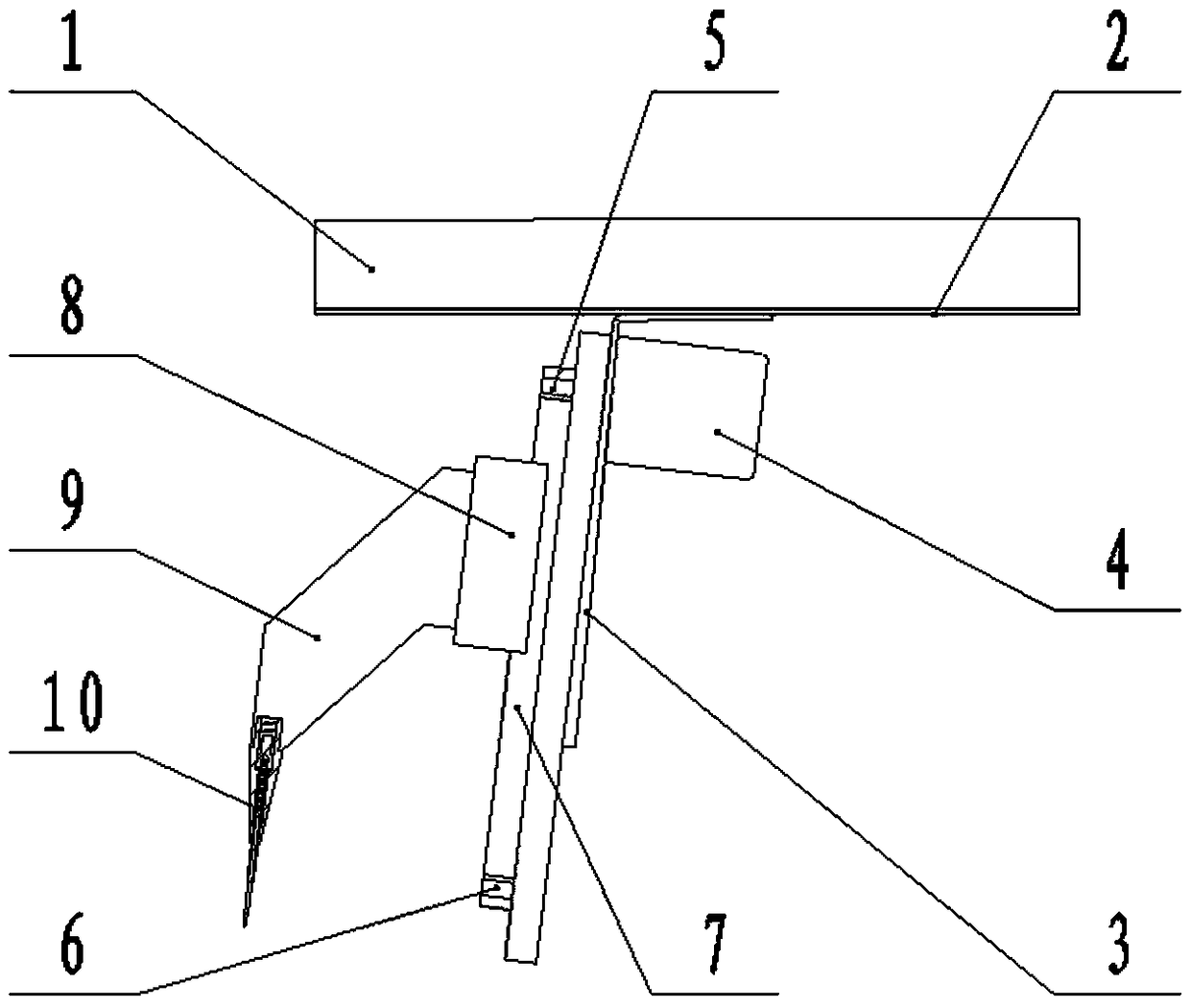

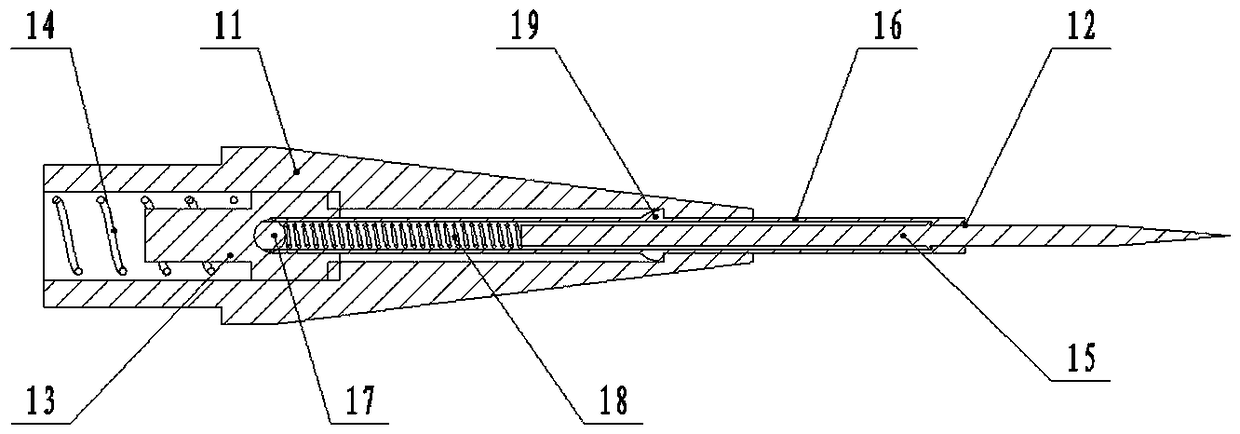

[0011] A high-precision probe loading device for PCB automatic test equipment, including a mover body 1 that moves along the X / Y direction of the test equipment. The support 3, the linear motor 4 is fixed on one side of the support 3, the other side of the support 3 is provided with a driving wheel 5 and a driven wheel 6, the driving wheel 5 is connected with the output shaft of the linear motor 4, and the driving wheel 5 and the driven wheel 6 is provided with a transmission belt 7, the transmission belt 7 is provided with a slider 8, the slider 8 is provided with an insulating block 9, the lower end of the insulating block 9 is provided with a probe assembly 10, and the probe assembly 10 includes a The sleeve 11 in 9 has a probe 12 inside the sleeve 11. The tail of the probe 12 has a stepped positioning block 13 that is in contact with the inner wall of the sleeve 11. The tail of the stepped positioning block 13 is covered with a contact with the insulating block 9. The buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com