A Micro Force Measuring Machine

A dynamometer, micro-force technology, applied in force/torque/work measuring instruments, metering using force-balanced force, measuring devices, etc., can solve the problems of low efficiency, long detection process time, few and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

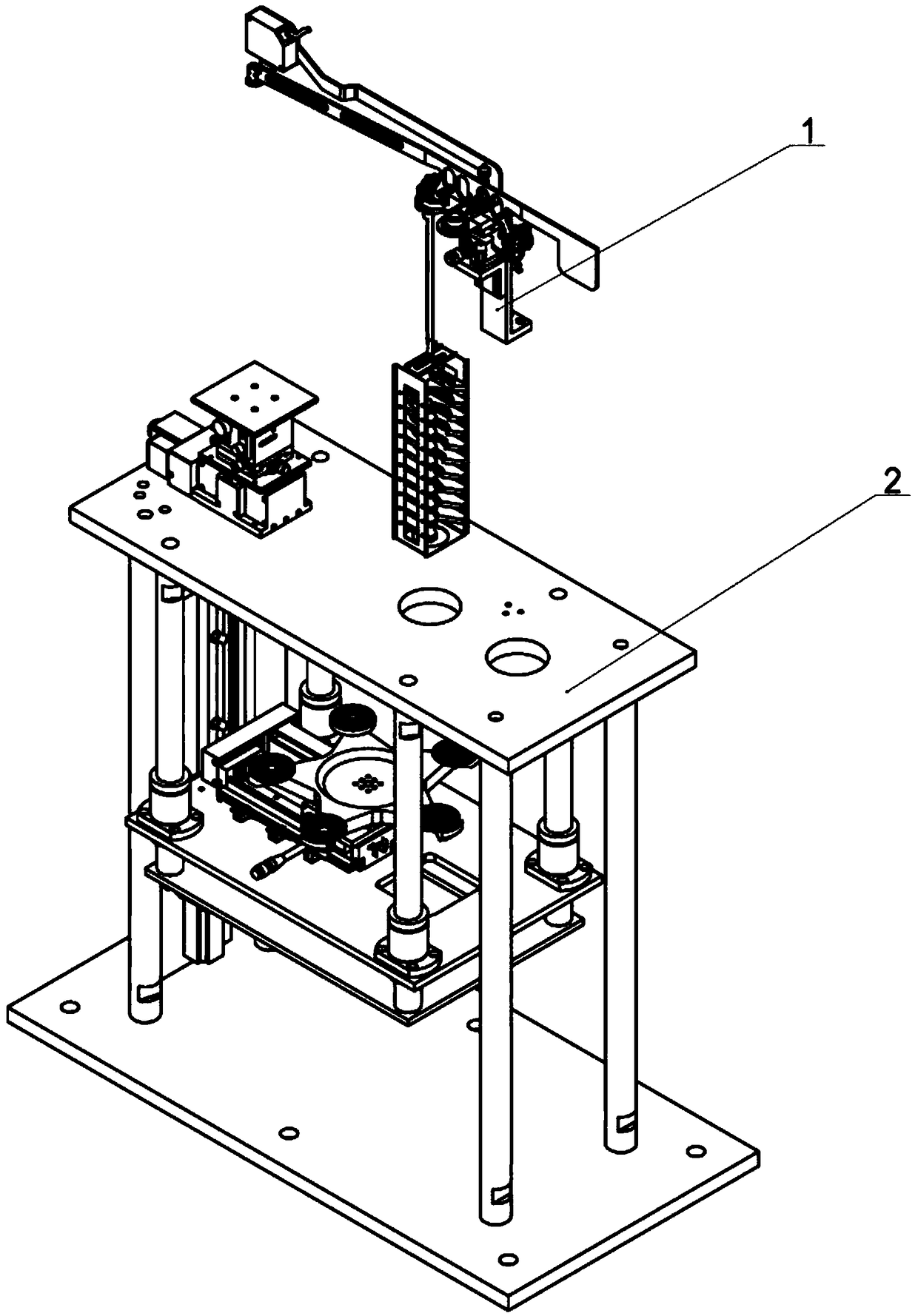

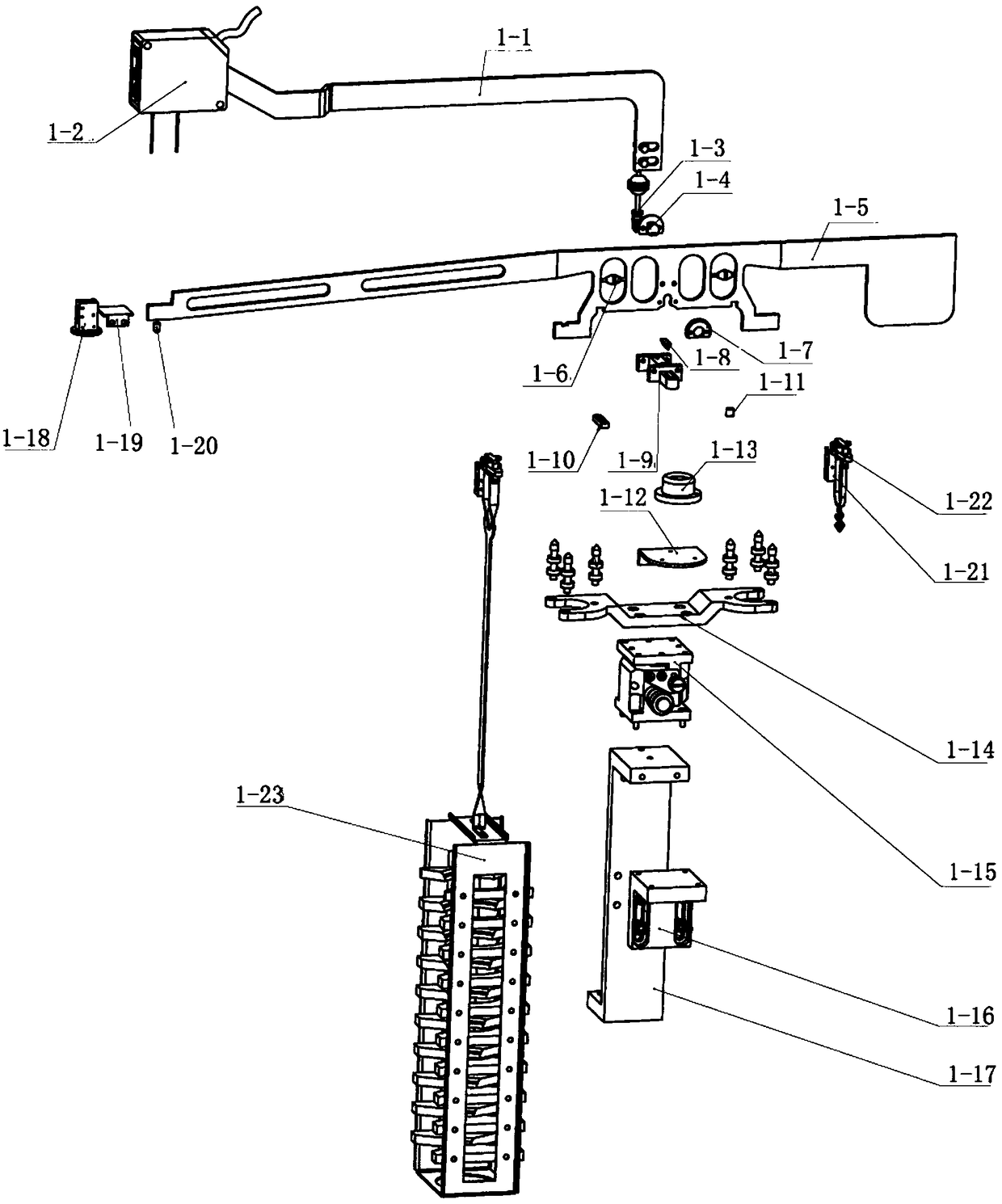

[0018] Such as figure 1 As shown, the present invention provides a micro-force dynamometer, which includes a lever-type measuring component 1 and a weight moving component 2 , and the lever-type measuring component 1 is installed on the weight moving component 2 . Among them, such as figure 2 As shown, the lever type measurement assembly 1 includes a sensor bracket 1-1, a laser sensor 1-2, an adjustment nut 1-3, a center knife rest 1-4, a balance beam 1-5, an adjustment counterweight 1-6, and a center knife rest Fixed plate 1-7, center knife 1-8, lever knife pad 1-9, lever horizontal fixed block 1-10, lever circular fixed block 1-11, level support plate 1-12, center level 1-13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com