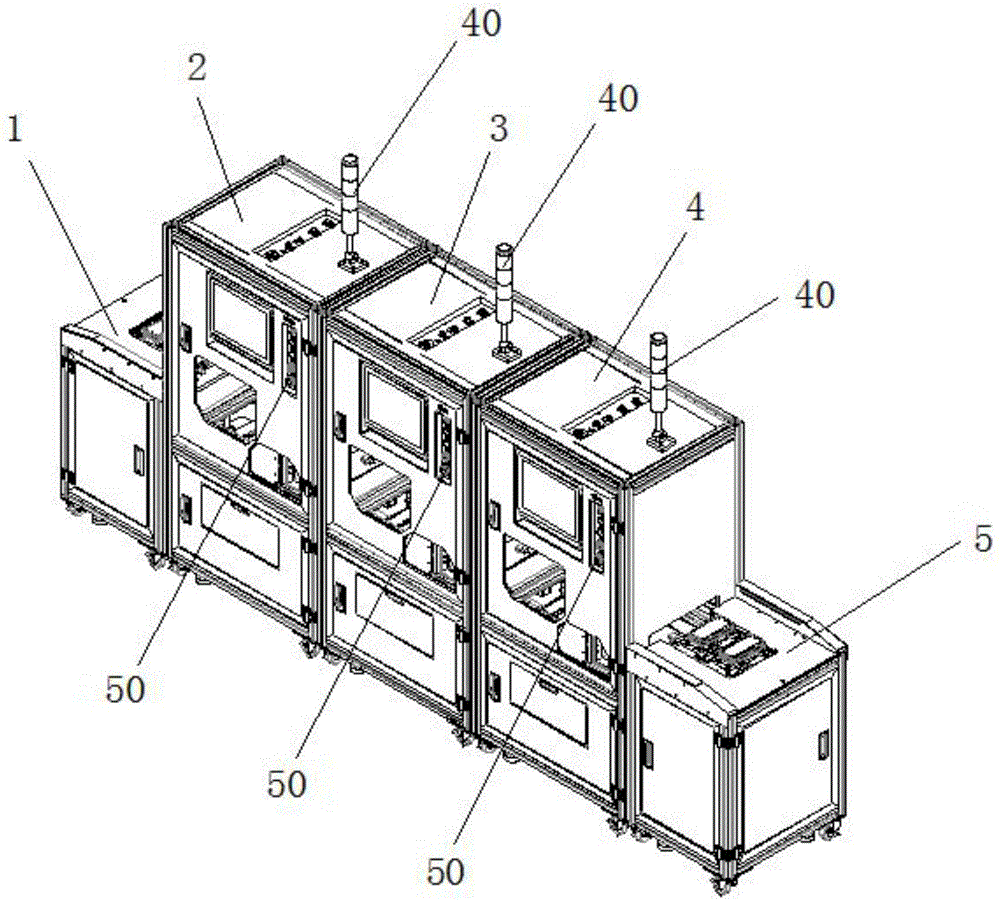

Automatic assembly line type cellphone online testing method and system

An on-line test and flow-through technology, applied in measuring devices, telephone communications, instruments, etc., can solve problems such as low test efficiency, high manpower and time costs, and complicated communication process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

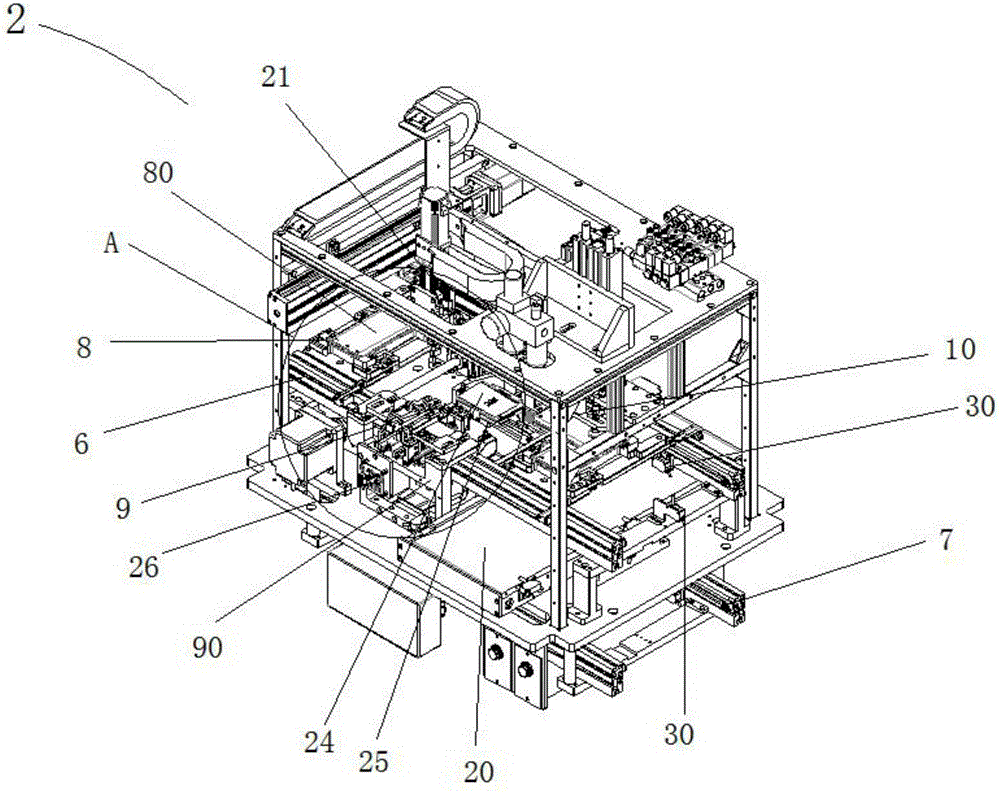

Embodiment 1

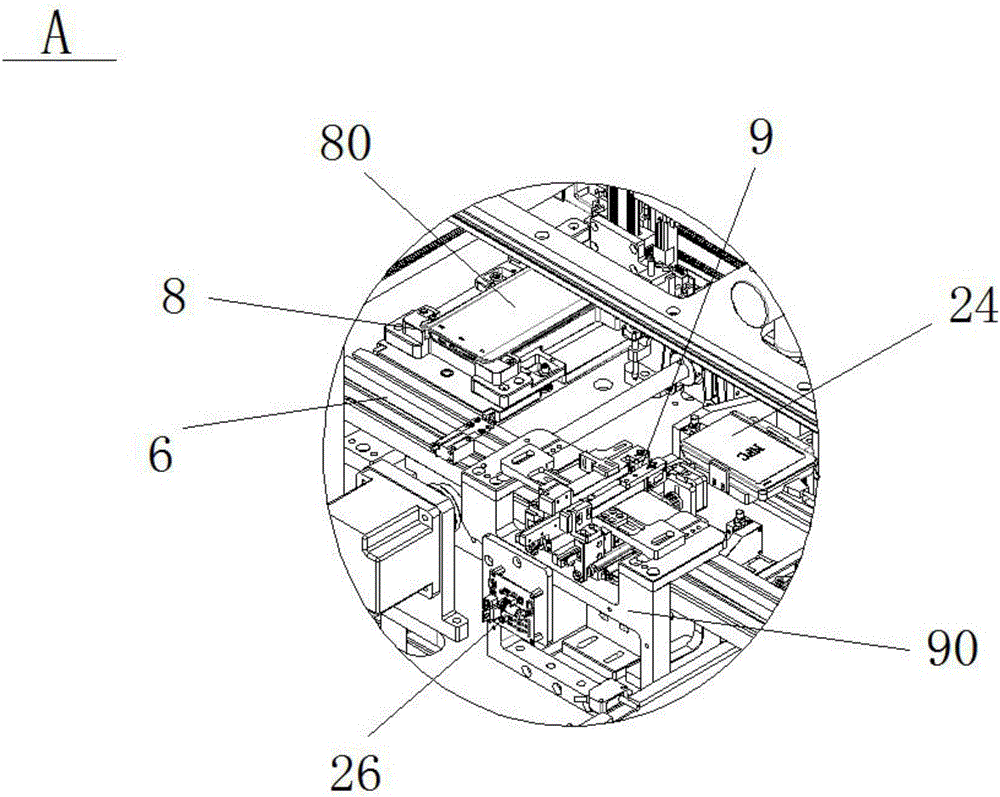

[0075] In this embodiment, on the No. 1 test platform 2, the key-press test, the double-click wake-up function test, the NFC card mode test, the flashlight test and the OTG function test are sequentially performed on the mobile phone to be tested. Specifically: in the step (2), a driving assembly 21 is provided on the upper end of the No. 1 test bench 2 and above the upper conveying track 6, the driving assembly 21 includes a horizontal cylinder 211 and a vertical cylinder 212, and An NFC card reader 24 and a first photoelectric sensor 25 are arranged below the conveying track 6. The NFC card reader 24 is set on the No. 1 test bench 2 through the first adjustment mechanism. On the USB plug-in mechanism 9 of No. 1 test bench 2 and being positioned at the upper conveying track 6 front ends, an OTG function test board 26 is arranged, and an electronic switch is arranged on this OTG function test board 26; Described step (4) specifically includes The following steps:

[0076] (4....

Embodiment 2

[0083] In this embodiment, when the mobile phone 80 to be tested after carrying out the function test on the No. 1 test platform 2, carry out the No. 2 test platform 3 along with the test vehicle 8, and carry out the FM test on the No. 2 test platform 3 successively for the mobile phone to be tested. , Headphone button test, electroacoustic transmission test, electronic compass test, NFC reading mode test, photosensitive test, touch screen self-test test and screen brightness test. Specifically: in the step (2), the No. 2 test bench 3 is provided with an FM transmitter 31, an earphone jack 32 and a first area array light source board 33, and the earphone jack 32 is positioned at the upper delivery track 6- side, and its upper end is located above the upper delivery track 6, and is symmetrically arranged on the USB plug-in mechanism 9; on the second test bench 3 and below the upper delivery track 6, a second photoelectric sensor is arranged, and the upper delivery track 6 An NF...

Embodiment 3

[0095] In the present embodiment, when the mobile phone 80 to be tested after carrying out the functional test on the second test platform 3, carry out the No. 3 test platform 4 along with the test vehicle 8, and the indicator lights on the mobile phone to be tested are carried out successively on the No. 3 test platform 4. Test, Gravity Test, Gyroscope Test, Infrared Test, Hall Device Test, Diversity Antenna Test and Bluetooth Test. Specifically: in the step (2), a second area array light source board 41 is provided on the No. 3 test bench 4, and the second area array light source board 41 is connected to the No. On the platform 4, and the second area array light source board 41 is located directly above the upper conveying track 6, and the lower end surface of the second area array light source board 41 is provided with a sensor, a gray card and a magnet; There is an antenna platelet, and this antenna platelet is arranged on No. 3 test bench 4 by the 3rd adjusting mechanism;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com