A separate heat pipe evaporator heated by rotating flow

A separate heat pipe and swirling flow technology, applied in evaporators/condensers, indirect heat exchangers, heat exchanger shells, etc., can solve the problems of large liquid filling, large space occupation, and low heat transfer performance. Achieve the effects of improved pressure bearing capacity, concentrated and uniform return liquid, and compact structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

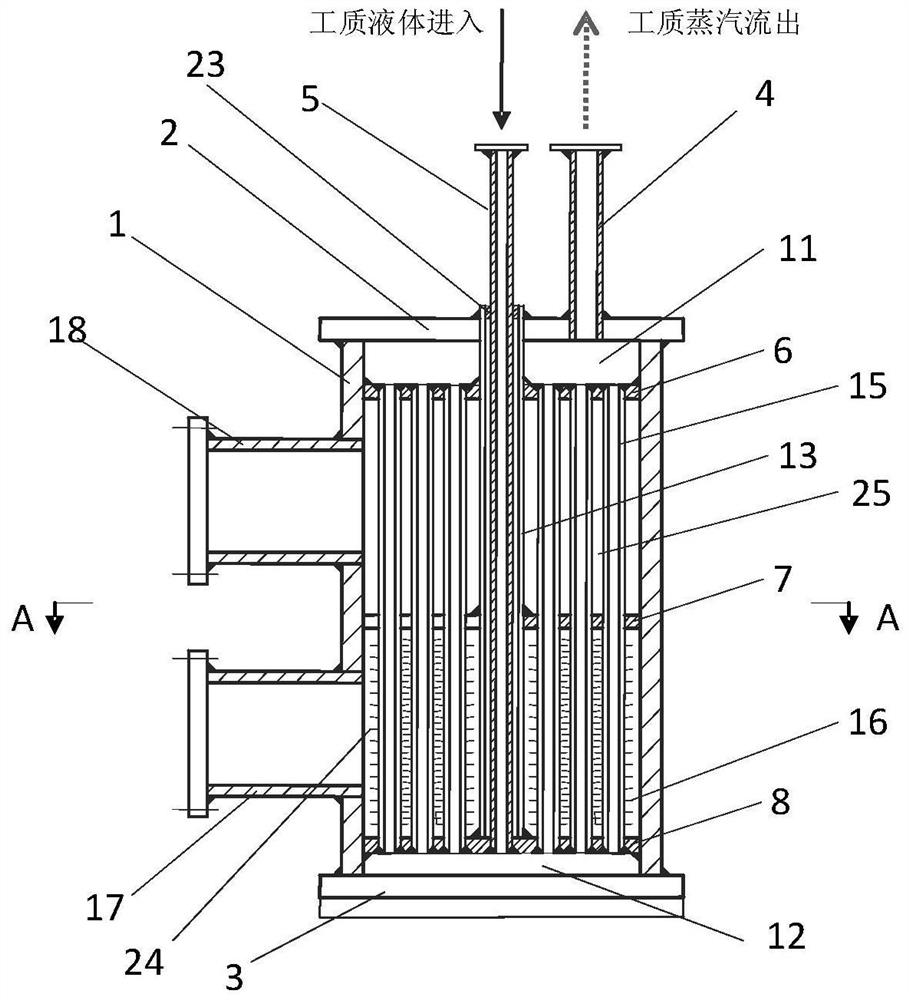

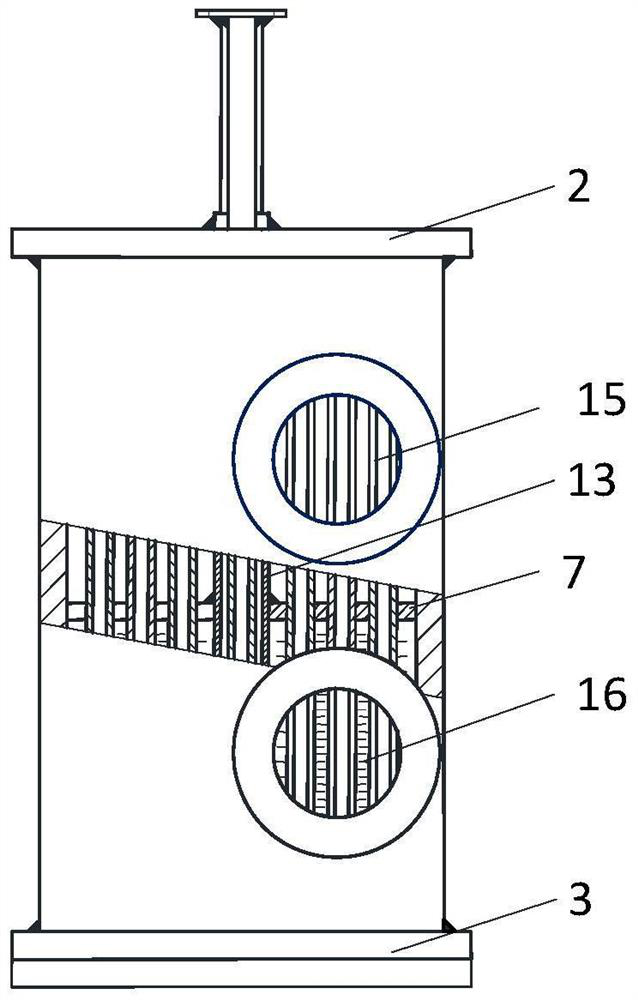

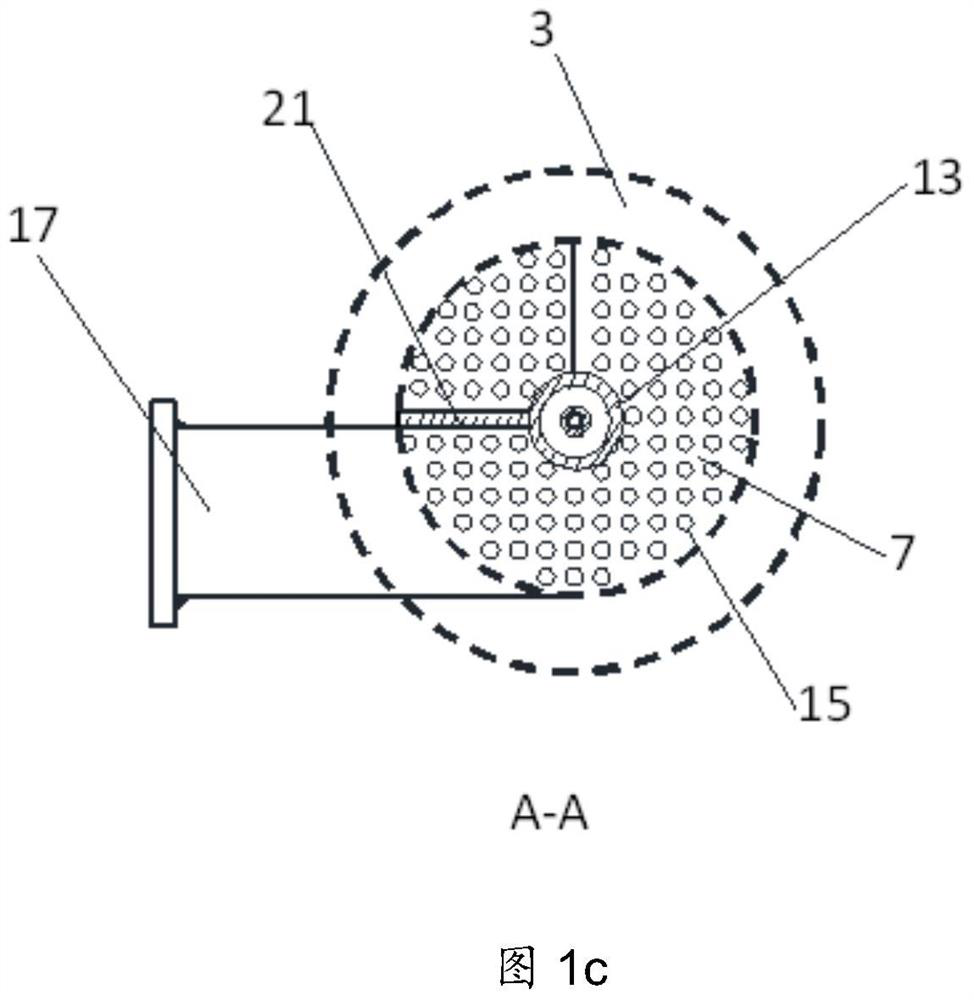

[0041] Such as figure 1 Shown are the three side views of the separated heat pipe evaporator heated by the swirling flow of the present invention, wherein Figure 1a main view, Figure 1b for the side view, figure 1 c is a top view. figure 1 The structural design of the evaporator with a cylindrical shell is given, and the cylindrical evaporator is taken as an example to describe in detail below. Depend on figure 1 It can be seen that the evaporator of the present invention includes a shell 1, an upper end cover 2, a lower end cover 3, a steam outlet pipe 4; a liquid pipe 5, an upper partition 6, n middle partitions 7 of heat exchange fluids, a lower partition 8, a steam chamber 11, Liquid chamber 12, isolation pipe 13, evaporation pipe 15, fins 16, heat exchange fluid inlet pipe 17, heat exchange fluid outlet pipe 18, heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com