Combined heating and cooling type method and system for copious cooling liquefied air

A technology for supplying system and liquid air, applied in the fields of thermal energy supply system and cold energy supply system, can solve the problems of energy waste, incomplete utilization of thermal energy and cold energy surplus, and achieve the effect of improving utilization rate and avoiding thermal energy loss and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a thermal energy supply method, including the following steps:

[0039] Step 1: Use electric energy to convert gaseous air into liquid air under low temperature and high pressure conditions;

[0040] Step 2: collecting the heat energy released during the conversion process of step 1;

[0041] Step 3: Use the heat energy collected in step 2 to supply heat energy.

[0042] The above steps are the core technical solution of this embodiment, generating thermal energy by compressing gaseous air into liquid air, collecting and storing the thermal energy, and supplying the collected and stored thermal energy to the thermal energy receiving end. In the existing liquefied air energy storage technology, the heat energy released in the energy storage stage is often collected and only used for heating during the gasification process of liquid air. In this embodiment, the remaining waste heat in the heat storage process is stored and used In order to suppl...

Embodiment 2

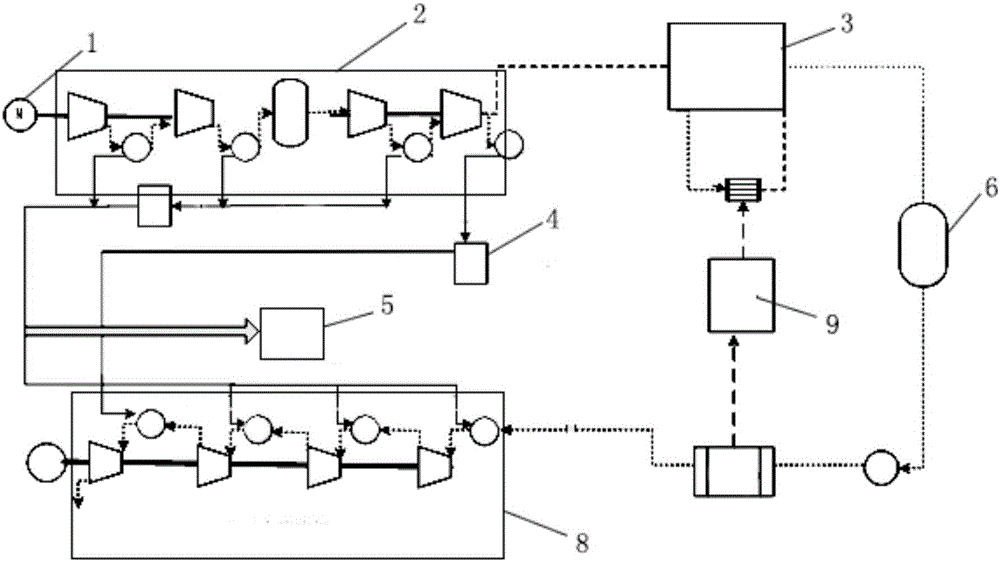

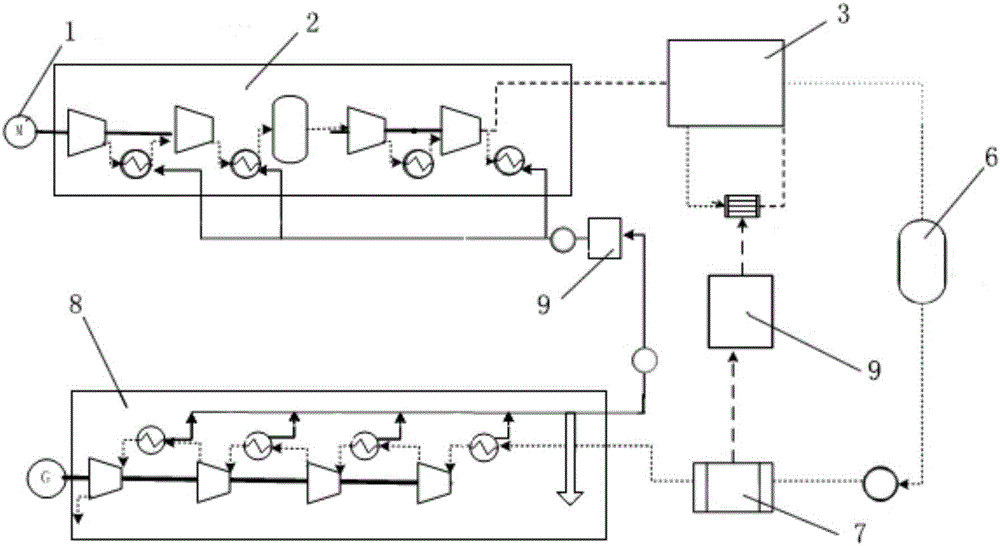

[0046] refer to figure 1 , this embodiment provides a thermal energy supply system, using the supply method described in Embodiment 1, the system includes: a motor 1, an air compressor unit 2, a liquefaction device 3, and a heat storage device 4, the motor 1 is used to drive The air compressor unit 2 and the liquefaction device 3 are used to convert gaseous air into liquid air, and the heat storage device 4 is used to collect heat energy released during the conversion process. Specifically, the air compressor unit 2 is preferably two groups, wherein the first group of air compressor unit is a low-pressure compressor unit, and the air compressed by the low-pressure compressor unit enters the air purification device, then passes through the second group of air compressor unit, and finally is liquefied Liquefaction was completed in unit 3. The heat storage device 4 can be a heat storage tank or the like, which is connected to each of the compressor units to absorb the heat energ...

Embodiment 3

[0050] This embodiment provides a cold energy supply method based on the heat energy supply method in Embodiment 1. Since the liquefied air energy storage technology is a cycle in which air is compressed into a liquid state and then expanded from a liquid state to a gas state, cold energy and heat energy The supplies are also preferably closely coupled to each other. The cold energy supply method of this embodiment includes the following steps:

[0051] Step 4: Collect the liquid air prepared in Step 1;

[0052] Step 5: Convert the Yetai air into gaseous air under high temperature and high pressure conditions, and collect the cold energy released during the conversion process;

[0053] Step 6: Use the cold energy collected in step 5 to supply cold energy.

[0054] Similar to the thermal energy supply method in Embodiment 1, in this embodiment, the cold energy generated during the liquid air vaporization process is collected, and then the collected cold energy is supplied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com