Vacuum feeding system for nori puffed food production

A technology of puffed food and feeding system, which is applied in the direction of conveying bulk materials, conveyors, chemical instruments and methods, etc., which can solve the problems of limited output, easy blockage of filter equipment, difficulty in adapting to large-scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings:

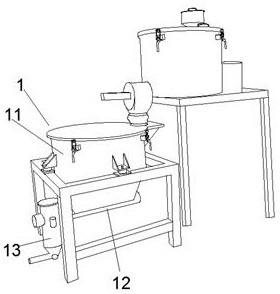

[0042] Such as Figure 1-13 , The present embodiment provides a puffed food production Seaweed vacuum feeding system 1 comprises a storage tank, and accurate delivery device apparatus 2 vacuum generator 3.

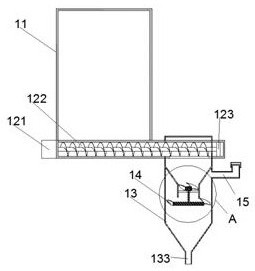

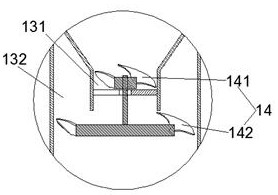

[0043] Storage tank 1 comprises a barrel body 11, an extrusion device 12, the tub 13 and the relay break up device 14, the extrusion apparatus 12 is mounted on the lower end of the bowl 11 and the output of an extrusion apparatus 12 in communication relay barrel 13, an extrusion apparatus 12 the raw material used in the bowl 11 to the transit extruder barrel 13, there will be a blocking phenomenon due to the extrusion apparatus 12 with a squeezing action on material, material transfer into the bucket 13, the bucket 13 is provided with the transfer material passage 131 and flow channel 132, break means 14 is rotatably mounted in the tub 13 and the transfer device 14 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com