Minitype rubber bag accumulator for shock absorber

A technology of shock absorbers and accumulators, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., and can solve the problems of oil chamber and air chamber isolation seal failure, reduced automobile shock absorption effect, and frequent movement of floating pistons and other problems, to achieve the effect of excellent heat insulation, easy installation, and difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

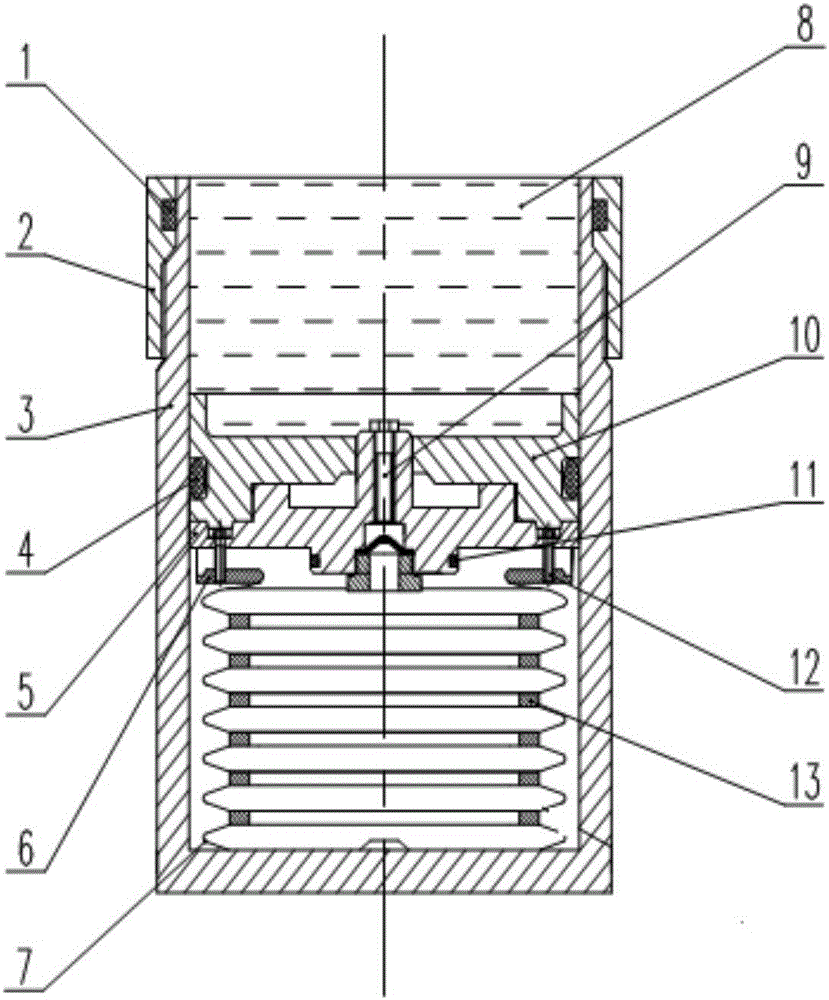

[0024] For further elaborating the present invention, now in conjunction with accompanying drawing, the present invention is further described:

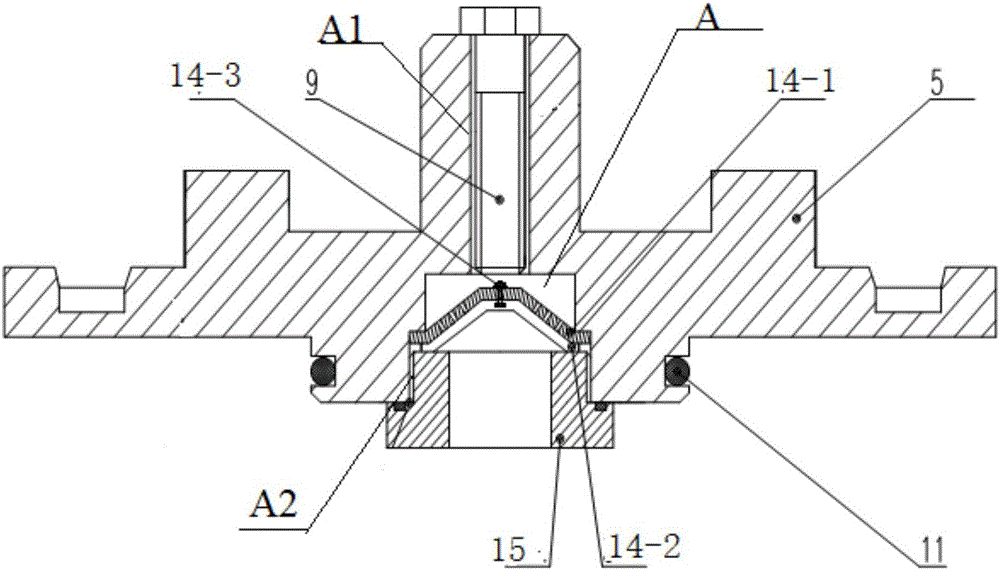

[0025] combined with figure 1 , the outer cylinder 2 and the inner cylinder 3 are connected by threads, wherein an annular groove C is opened on the inner ring of the outer cylinder 2, and an O-ring A1 is installed in the annular groove C, so that the outer cylinder 2 and the inner The sealing of the cylinder 3 ensures that the shock absorbing oil 8 will not leak on the contact side of the outer cylinder 2 and the inner cylinder 3; in addition, the upper end of the junction of the outer cylinder 2 and the inner cylinder 3 is engaged; the inner cylinder 3 Among them, the bladder 7, the air-filled sealing flange 5, the floating piston 10, and the shock absorbing oil 8 on the floating piston 10 are arranged in sequence from bottom to top, wherein the bladder 7 has a folded structure, and is composed of a plurality of flat curved bladder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com