Big gear ring connecting structure of barium sulfate raw material calcining furnace

A connection structure, calciner technology, applied in the direction of calcium/strontium/barium sulfate, elements with teeth, belts/chains/gears, etc., can solve the problems of limited use range, poor practicability, increased vibration, etc. , to achieve the effect of low level of personnel participation, simple structure and working principle, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

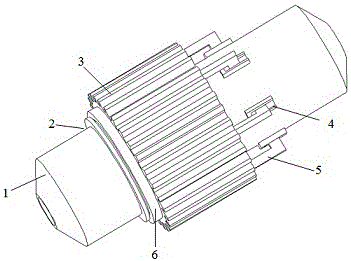

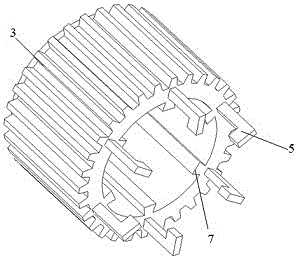

[0017] Compare below figure 1 -3 to explain, in the traditional situation, the rotation of the rotary kiln 1 mainly depends on the transmission of the cylindrical gear 3 and the large ring gear on the furnace body. The large ring gear of the rotary kiln 1 is basically rigidly connected by lateral bolts. Before the device works, the connection of each component should be checked, especially whether the fixation of the rotary kiln 1 is reliable, and the connection of the cylindrical gear 3 on the rotary kiln 1 is to ensure that the components are connected reliably. To avoid safety accidents in which parts fall and injure people, the device has completed its preparatory work so far.

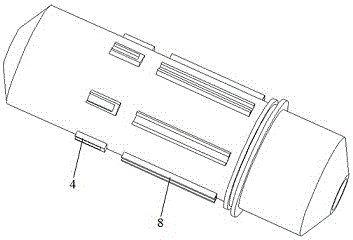

[0018] When the device is working, the clay raw material to be calcined is added from the upper end of the rotary kiln 1, and the rotary kiln 1 needs to rotate during the working process. Sleeved on the clasp 2, the other end is connected with the guide rod 5, the guide rod 5 slides in the axial g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com