Hydrodynamic Optimization Method of Hydraulic Valve

An optimization method and hydraulic valve technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of a large number of manual calculation and screening, low design work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

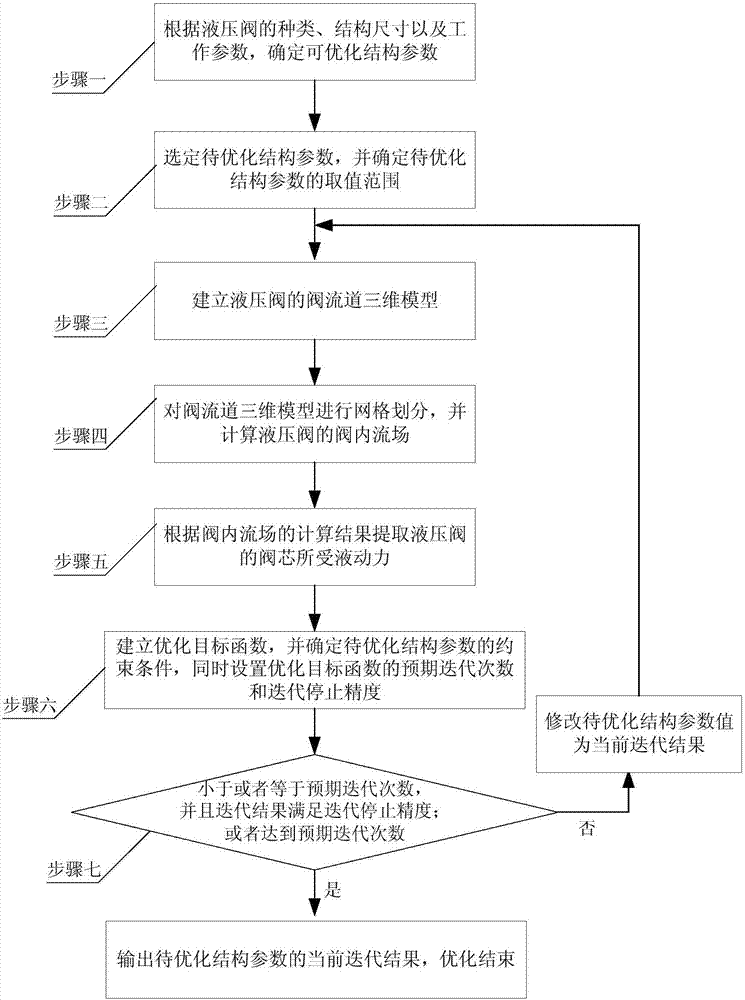

[0019] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the hydraulic power optimization method of hydraulic valve described in this embodiment, it comprises the following steps:

[0020] Step 1: Determine the structural parameters that can be optimized according to the type, structural size and working parameters of the hydraulic valve;

[0021] Step 2: Select the structural parameters to be optimized from the structural parameters that can be optimized, and determine the value range of the structural parameters to be optimized;

[0022] Step 3: According to the current structural size of the hydraulic valve, establish a three-dimensional model of the valve channel of the hydraulic valve;

[0023] Step 4: Mesh the 3D model of the valve channel, and calculate the valve flow field of the hydraulic valve;

[0024] Step 5: Extract the hydraulic force on the spool of the hydraulic valve according to the calculation result of the flow...

specific Embodiment approach 2

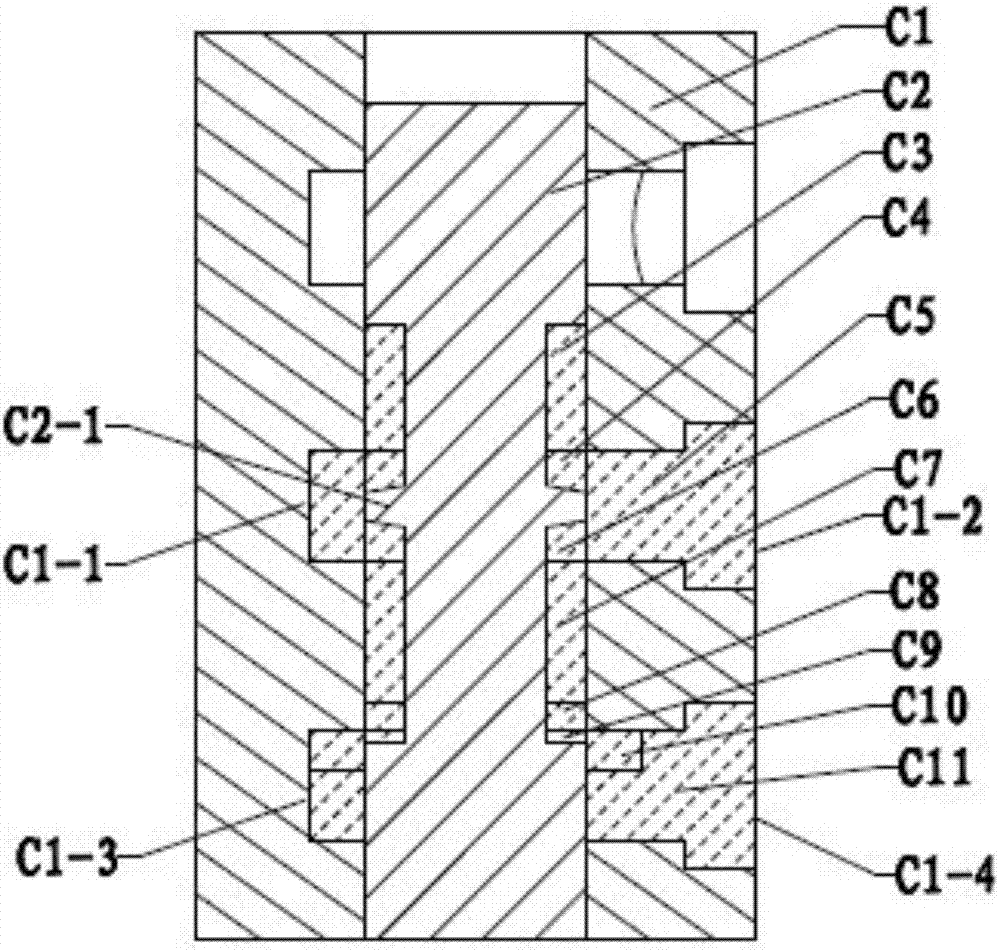

[0028] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain Embodiment 1, the hydraulic valve is a slide valve,

[0029] In step 1, the structure of the spool valve includes a valve core and a valve body; three shoulders on the valve core and two sinking grooves on the valve body; the end surface of the lower shoulder of the valve core cooperates with the sinking groove of the valve body to form a throttle valve The middle shoulder of the spool is a hydrodynamic compensating shoulder, which is located in the middle of the second sinking groove on the valve body; the upper shoulder of the valve core seals the valve chamber; the sinking groove on the valve body is connected to the outside through port 1 , the upper sinking groove is connected to the outside through oil port 2;

[0030] The structural dimensions of the spool valve include the diameter of the spool and the opening of the valve port, a...

specific Embodiment approach 3

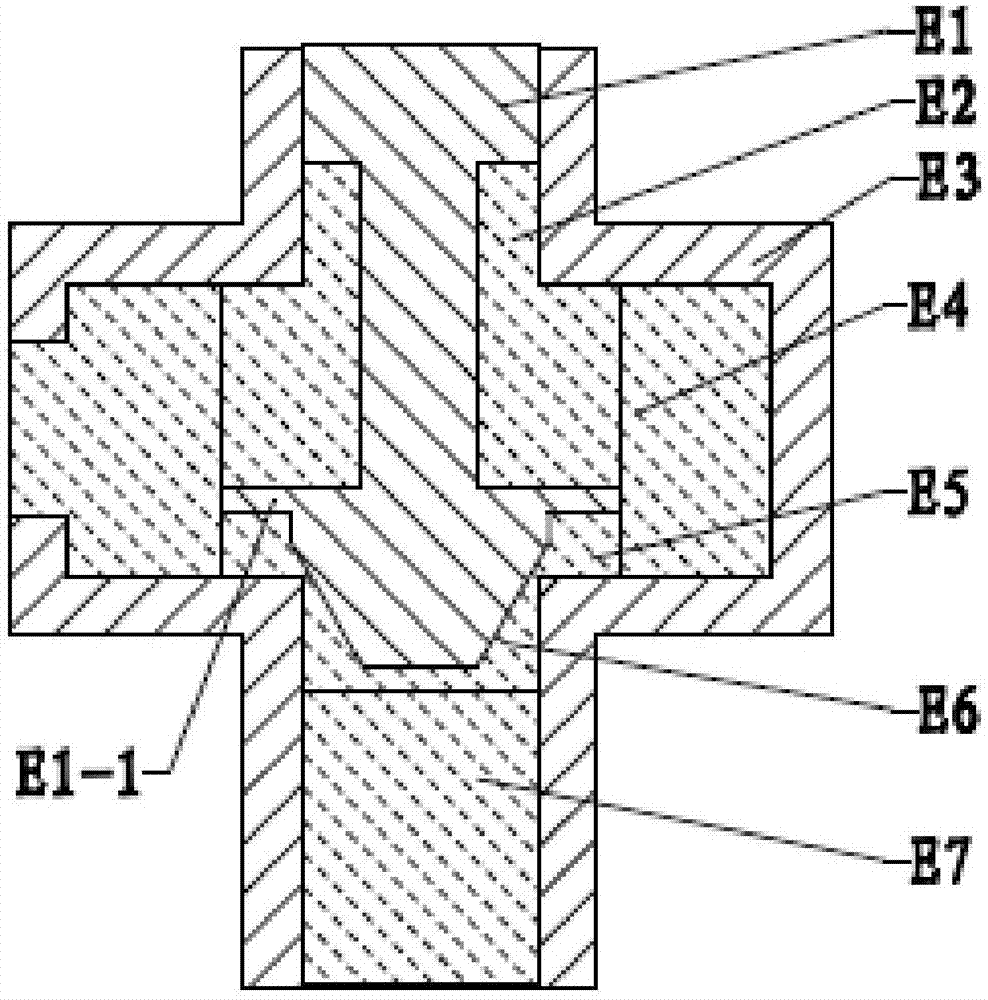

[0052] Specific implementation mode three: the following combination image 3 Describe this embodiment, this embodiment will further explain Embodiment 1, the hydraulic valve is a cone valve,

[0053] In step 1, the structural dimensions of the poppet valve include the diameter of the valve seat hole, the opening of the valve port, the diameter of the valve core guide section, and the diameter of the inlet and outlet; the working parameters of the poppet valve are determined as inlet pressure and outlet pressure, working flow and inlet pressure or working flow rate and outlet pressure; determine the optimized structural parameters of the cone valve as the diameter of the cone valve's hydrodynamic compensation baffle and the distance between the hydraulic compensation baffle and the valve port;

[0054] In step 2, select and determine one or any several of the structural parameters that can be optimized as the structural parameters to be optimized;

[0055] In step 3, divide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com