A delayed grouting method for single shield tbm wall

A single-shield, grouting technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as affecting equipment operation, unable to continue construction, and uneven grouting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

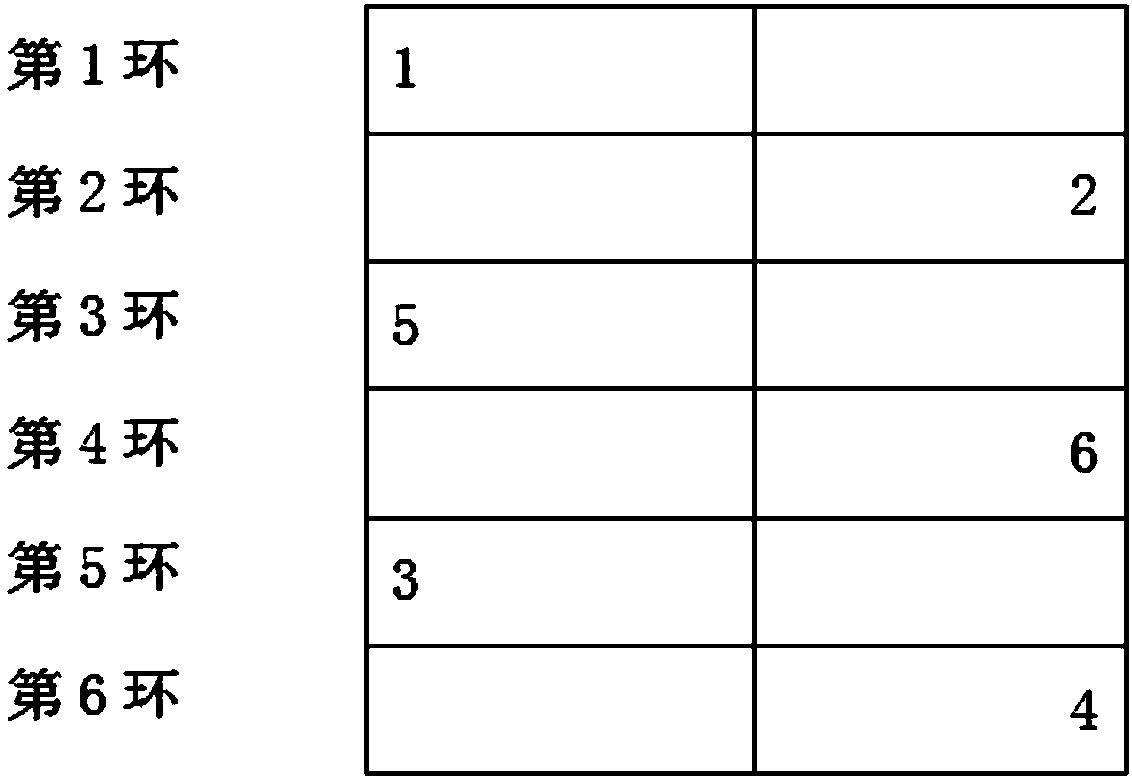

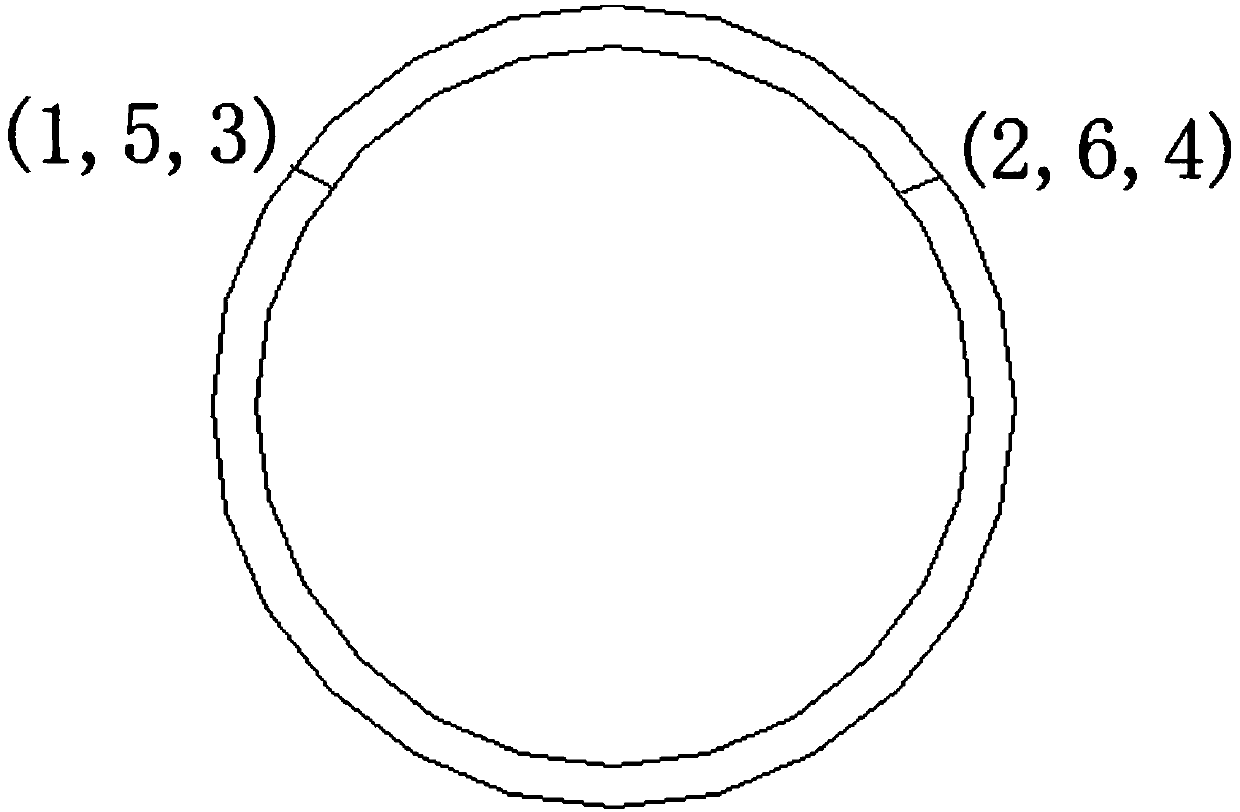

[0017] This specific implementation mode adopts technical scheme: its operation process:

[0018] 1. Before starting grouting, check whether the grouting equipment is operating normally, so as to avoid shutdown due to failure during construction and affect the progress. Check whether the grouting pipe is unobstructed, and whether the hoisting hole cover is not screwed on or not tightened, so as to prevent the cement slurry from flowing out of the hoisting hole during grouting. Due to the setting effect of the grout, it is necessary to avoid interruptions in the construction, or the event of waiting too long. The connection between each process should be smooth to prevent the slurry from solidifying and damaging the equipment.

[0019] 2. According to the calculation, each ring needs to be grouted 4m 3 , each truck carries 4m of slurry 3 The cement slurry is transported from the wellhead mixing station to the 1# trolley by the battery car, and then the trolley has its own pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com