Large-section inclined shaft open channel segment construction method and high-strength combined form board thereof

A technology combining formwork and construction method, applied in wellbore lining, shaft equipment, earthwork drilling, etc., can solve the problems of delay in the construction period of the open channel section, heavy supporting workload, and impact of topsoil excavation, saving labor input, The effect of preventing soil collapse and smoothing the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

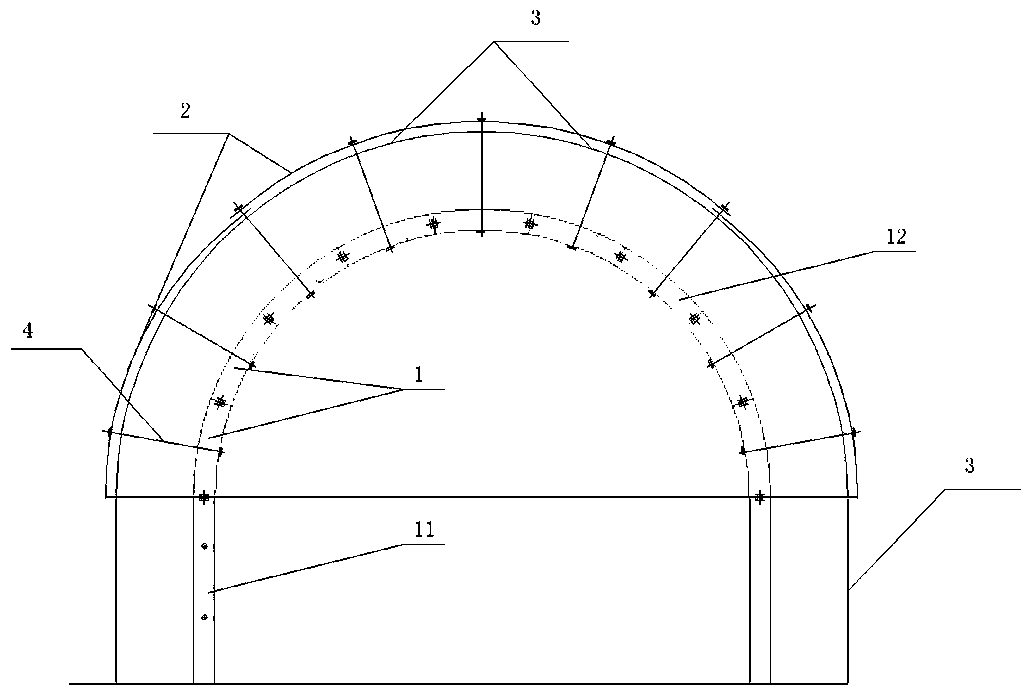

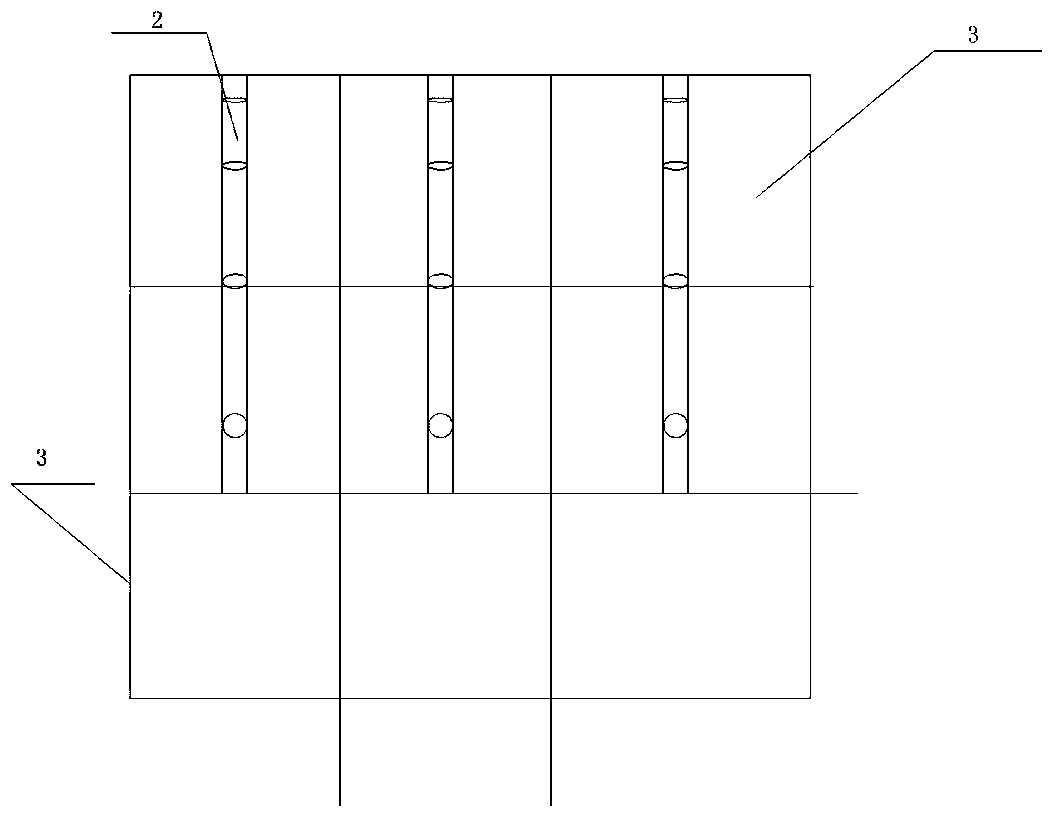

[0029] As shown in the figure, a high-strength composite formwork for the open trough section of a large-section inclined shaft includes an inner formwork and an outer formwork arranged on the outside of the inner formwork. Arc-shaped binding steel bars are also arranged between the inner formwork and the outer formwork, so The inner formwork is assembled by multiple combined formwork 1, each combined formwork 1 is composed of four legs 11 and nine combined arch plates 12. The outer formwork includes steel slats 2 and nine slabs 3. The steel slats 2 It is fixedly connected to the inner template by the nine-centimeter board 3 and the extension bolt 4.

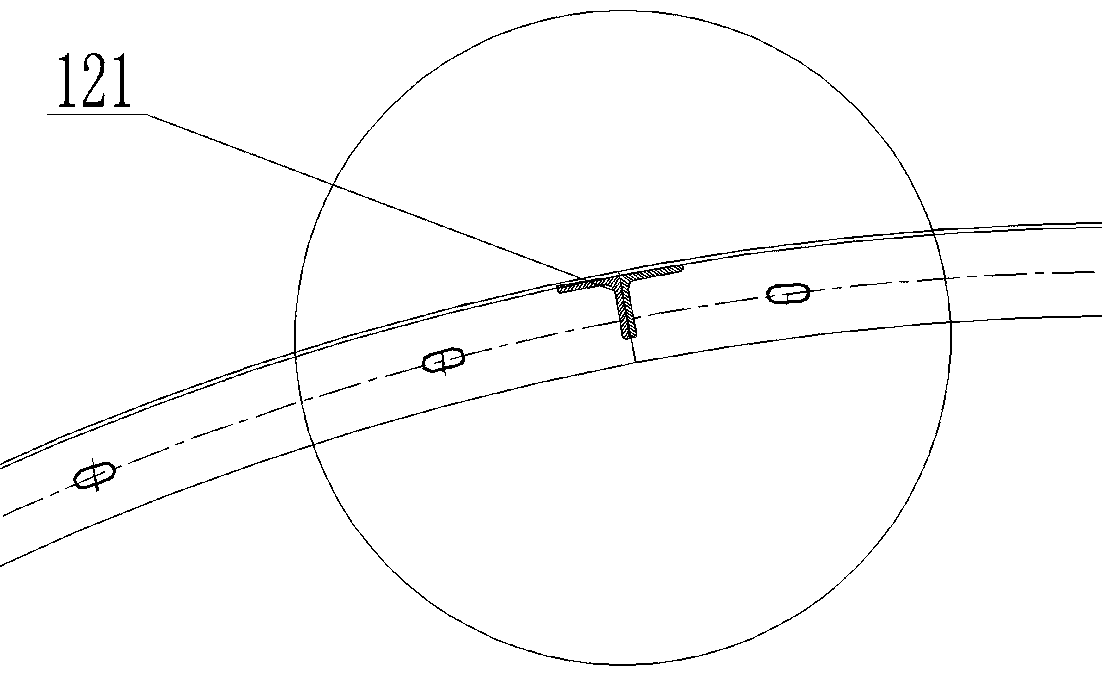

[0030] Furthermore, the edge of each combined arch 12 is provided with a connecting lug 121, and two adjacent combined arches 12 are fixedly connected by bolts passing through the lug 121.

[0031] Further, each leg 11 is provided with connecting holes in the transverse and vertical directions, the adjacent legs 11 can be reinforced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com