Coal mine resource flow phase development equipment and development method based on tbm

A coal mine and fluid phase technology, applied in the field of coal mine resource mining and utilization, can solve the problems of aggravated surface pollution, low degree of mechanization, high labor intensity, etc., and achieve the effect of high maintenance cost of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

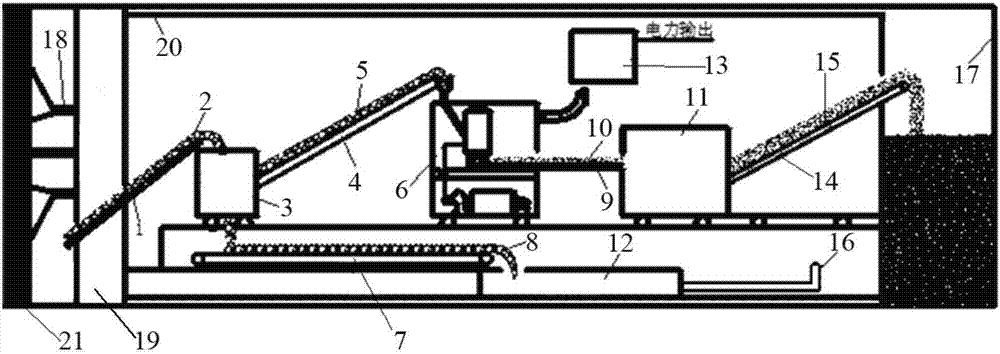

[0024] In this embodiment, the structural diagram of the coal mine resource flow phase development equipment based on TBM is as follows figure 1 As shown, the equipment includes a full-face boring machine including a cutter head 18 and a fluid phase development box 20. The cutter head 18 is connected to the fluid phase development box 20 through a connecting piece 19, and also includes a first conveyor belt 1, a fifth conveyor belt Belt 14, gas output pipeline 16, and coal mine separator 3 installed in the flow phase development box, second conveyor belt 4, generator set 6, third conveyor belt 7, fourth conveyor belt 9, filling material processing chamber 11 , gasification device 12 and wireless power transmission equipment 13. The full-section roadheader is a 160 series 155-274 full-section roadheader, produced by Robin Company of the United States, and the coal mine separator 3 is a ZKZ-4 linear vibrating screen machine, produced by Shandong Tai'an Coal Mining Machinery Co.,...

Embodiment 2

[0028] In this embodiment, the TBM-based coal mine resource flow phase development method of the present invention is provided. The method uses the equipment described in Embodiment 1, and the steps are as follows:

[0029] ① Excavate the vertical shaft from the surface to the underground coal mine layer to be mined, hoist the various components of the equipment described in Example 1 to the coal mine layer to be mined along the vertical shaft and install the equipment, connect the gas output pipeline 16 from the shaft to the gas storage room connection, the cement, cement powder and water storage area in the material storage area of the filling material processing chamber 11 are respectively connected from the vertical shaft to the cement, cement powder and water replenishment points on the surface through pipe fittings, and the cement, cement powder and water supply points are regularly supplied to the cement, cement Powder and water storage area replenishes cement, cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com