Multi-element coal-based solid waste composite acid excited underground filling material and preparation method thereof

A filling material and composite acid technology, which is applied in the field of multi-component coal-based solid waste composite acid excitation underground filling material and its preparation, can solve the problems of restricting the rapid development of ecological economy and society, low comprehensive utilization rate of solid waste, and land occupation. Achieve large-scale safe consumption and resource utilization, prevent environmental and economic problems, and save cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

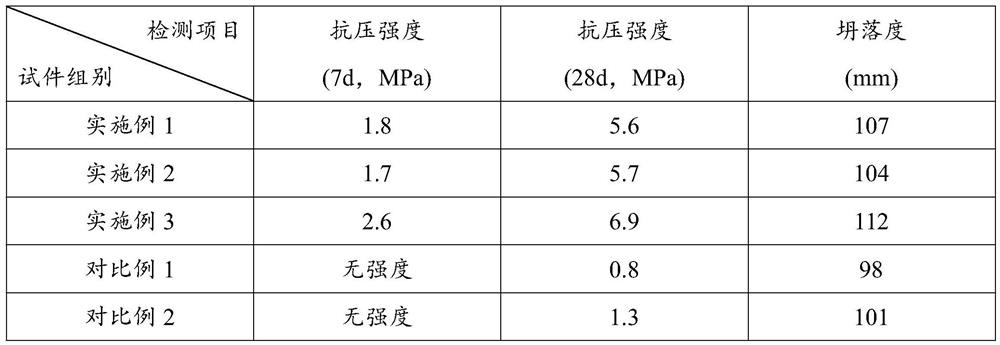

Examples

Embodiment 1

[0017] The preparation method of a multi-component coal-based solid waste composite acid-activated downhole filling material is as follows:

[0018] (1) Firstly, the coal gangue and furnace bottom slag are crushed into particle sizes below 25mm, each of which is formulated into a continuous gradation, and then the fly ash and gasification slag are respectively configured into a continuous gradation, and the 42.5-grade ordinary silicon Put the salt cement into the ball mill for continuous ball milling for 30 minutes to ensure that the particle size of the cement particles is less than 10um.

[0019] (2) Weigh 1800g of 42.5 grade ordinary Portland cement after ball milling, 200g of desulfurized gypsum and mix them evenly, 1000g of water and 40g of acetic acid, mix them evenly, weigh 7000g of well-graded fly ash, and 1000g of gasification slag And mix evenly, finally take by weighing well-graded coal gangue 11000g, furnace bottom slag 1000g and mix evenly;

[0020] (3) First, ad...

Embodiment 2

[0022] The preparation method of a multi-component coal-based solid waste composite acid-activated downhole filling material is as follows:

[0023] (1) Firstly, the coal gangue and furnace bottom slag are crushed into particle sizes below 20mm, and each is prepared into a continuous gradation, and then the fly ash and gasification slag are respectively prepared into a continuous gradation, and the 42.5-grade ordinary silicon Put the salt cement into the ball mill for continuous ball milling for 30 minutes to ensure that the particle size of the cement particles is less than 10um.

[0024] (2) Weigh 1600g of 42.5 grade ordinary Portland cement after ball milling, 250g of desulfurized gypsum and mix them evenly, 1200g of water and 40g of acetic acid, mix them evenly, weigh 6000g of well-graded fly ash, and 1100g of gasification slag And mix evenly, finally take by weighing well-graded coal gangue 10000g, furnace bottom slag 1200g and mix evenly;

[0025] (3) First, add the ace...

Embodiment 3

[0027] The preparation method of a multi-component coal-based solid waste composite acid-activated downhole filling material is as follows:

[0028] (1) Firstly, the coal gangue and furnace bottom slag are crushed into particle sizes below 25mm, each of which is formulated into a continuous gradation, and then the fly ash and gasification slag are respectively configured into a continuous gradation, and the 42.5-grade ordinary silicon Put the salt cement into the ball mill for continuous ball milling for 30 minutes to ensure that the particle size of the cement particles is less than 10um.

[0029] (2) Weigh 2000g of 42.5 grade ordinary Portland cement after ball milling, 300g of desulfurized gypsum and mix them evenly, 1000g of water and 30g of acetic acid, mix them evenly, weigh 7000g of well-graded fly ash, and 1200g of gasification slag And mix evenly, finally take by weighing well-graded coal gangue 12000g, furnace bottom slag 800g and mix evenly;

[0030] (3) First, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com