Withdrawal well equipment for underground coal gasification process and application of withdrawal well equipment

A technology for underground gasification and production of wells, applied in coal gasification, underground mining, boreholes/well components, etc., can solve problems such as high cost and complex structure, achieve equipment cost saving, safe and controllable operation, and improve reliability Effects on sex and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

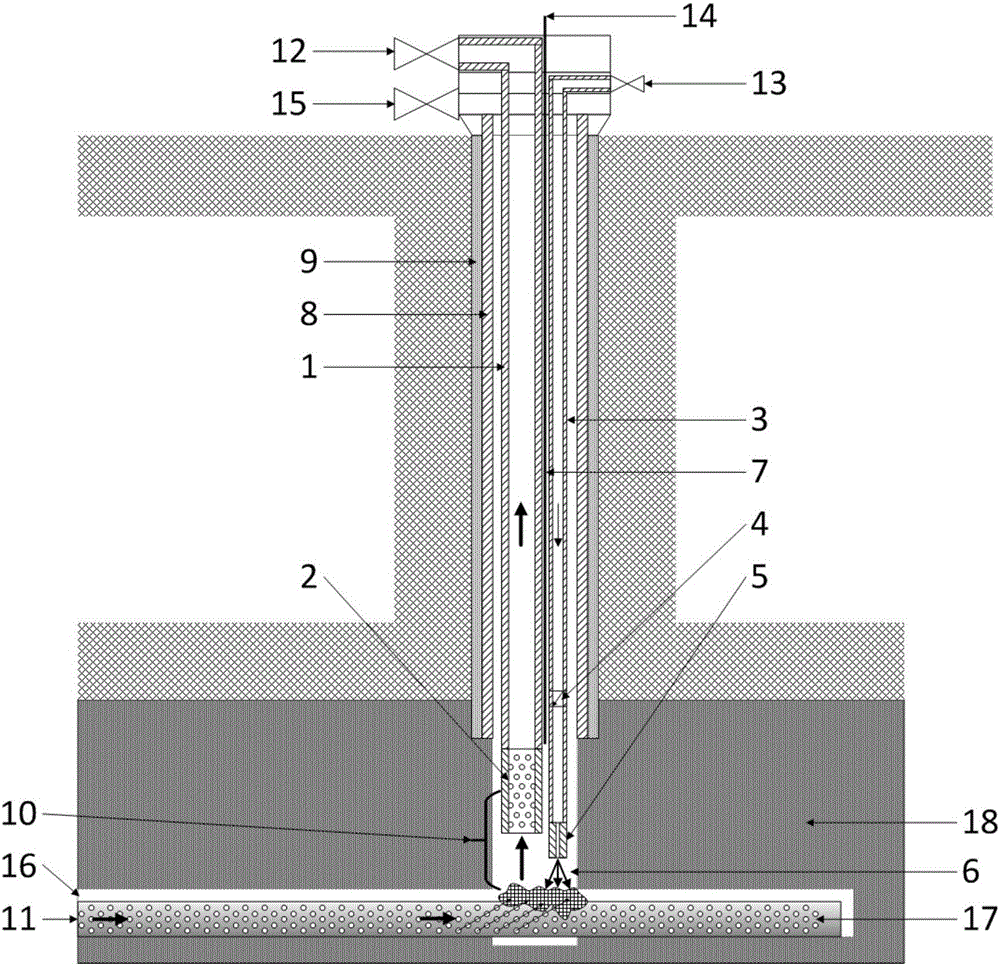

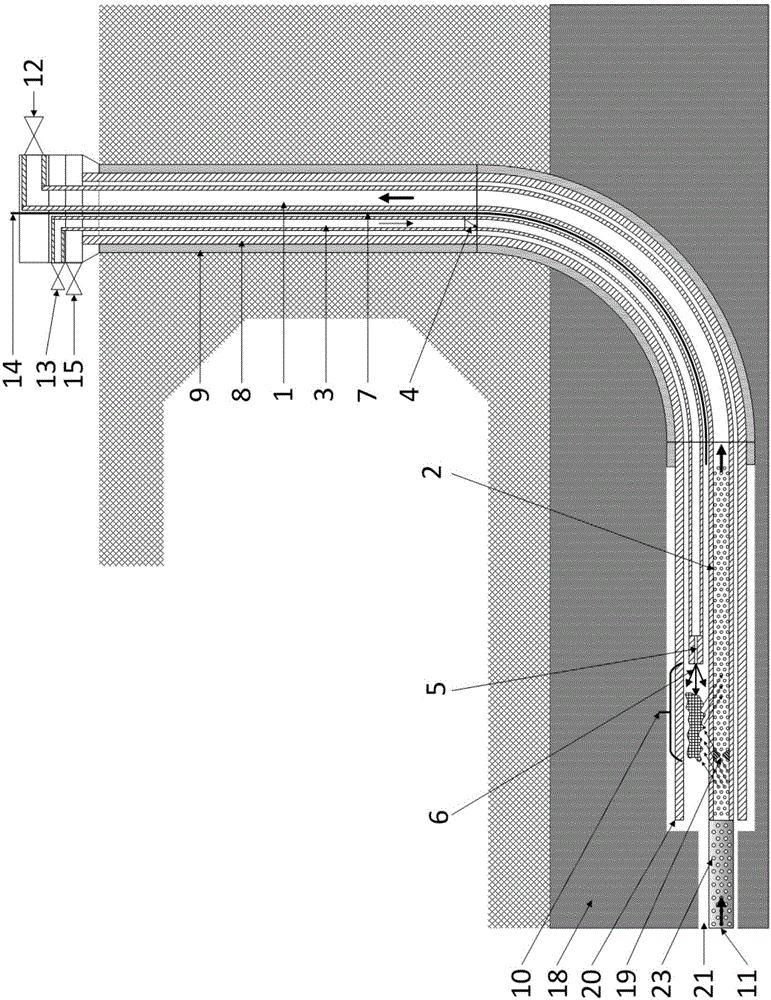

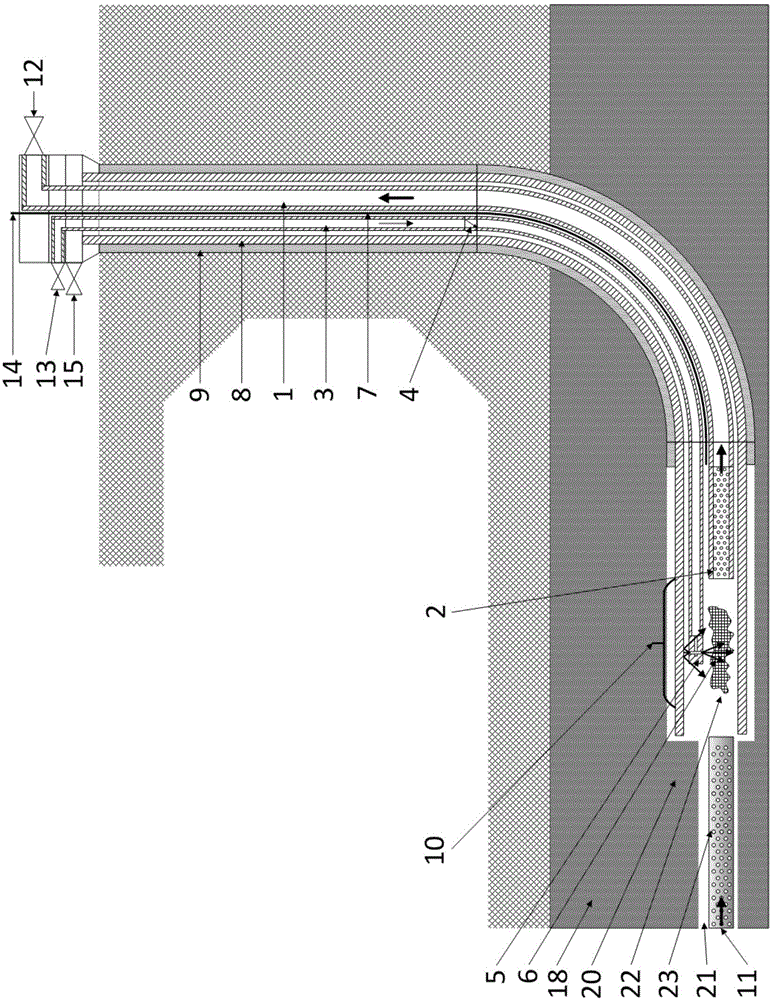

[0036] The invention provides a production well equipment used in an underground coal gasification process. In particular, the present invention provides a production well equipment that can remove product gas after cooling by injecting a coolant during the underground coal gasification process, and also provides the production well equipment in the underground coal gasification process. application.

[0037] According to the present invention, there is provided a production well equipment for the underground coal gasification process, the production well equipment includes wellhead equipment and casing, as well as product pipes, coolant pipes and monitoring instrumentation systems located in the casing, wherein :

[0038] The casing is used to reinforce and isolate the wellbore of the production well, and it is connected with a collar and thread and fixed in the wellbore of the production well through a cement layer;

[0039] The product pipe is used to transport the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com