Portable adsorption type natural gas recovery device and method

A recovery device and natural gas technology, applied in the direction of separation method, container filling method, container discharge method, etc., can solve the problems of high equipment requirements, existing safety, high pressure, etc., and achieve improved safety, convenient installation, and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

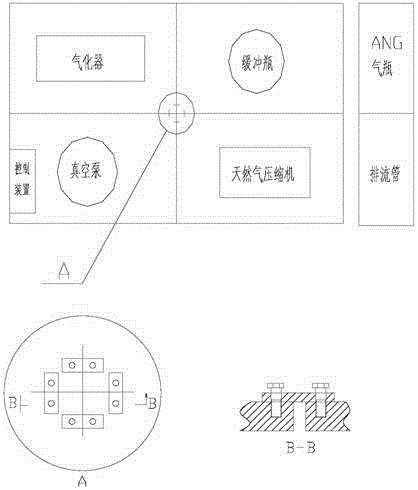

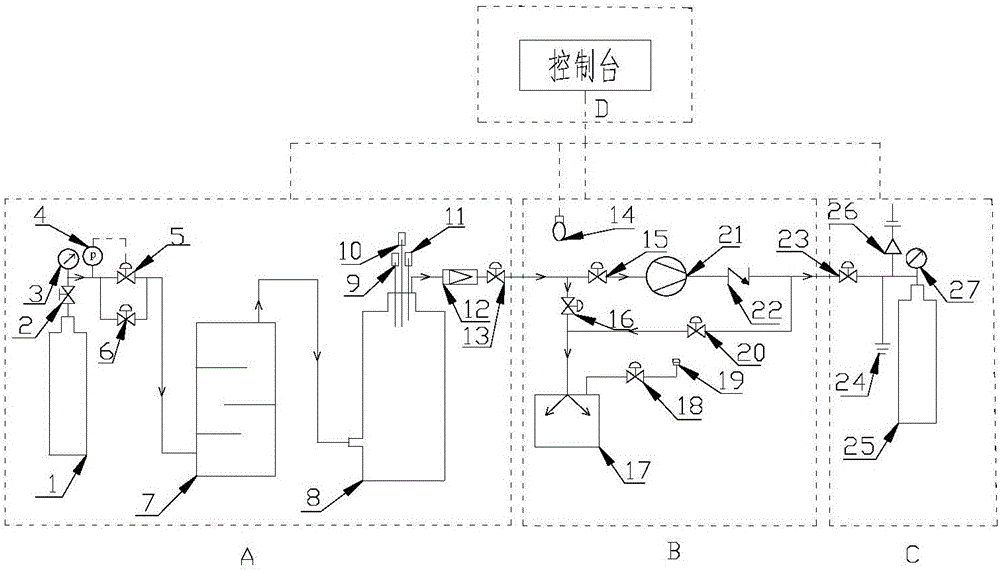

[0061] Recycle and reuse the residual gas of liquefied natural gas, the gas flow rate is 50m 3 / h, the gas temperature is lower than the ambient temperature, through the technical scheme of the present invention combined with the attached figure 1 Describe in detail.

[0062] (1) A portable adsorption-type natural gas recovery device includes: a gas collection module (A), a pump module (B), an adsorption module (C) and a control module (D); each module of the device is composed of a natural gas cylinder or LNG Bottle (1), manual valve (2), electric valve (5, 13, 15, 16, 18, 20, 23), pressure gauge (3, 27), pressure detection probe (4, 9), pressure regulator valve ( 6), vaporizer (7), buffer tank (8), oxygen detection probe (10), temperature detection probe (11), flow meter (12), combustible gas alarm (14), vacuum pump (17), vacuum Breathing valve (19), natural gas compressor (21), one-way valve (22), ground wire (24), ANG bottle (25), safety valve (26), and control cabinet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com