Preparation method of benzotriazole ultraviolet light absorber

A technology of benzotriazoles and ultraviolet rays, applied in the field of ultraviolet absorption, can solve environmental pollution and other problems, achieve the effect of reducing side reactions, reducing possibilities, and improving purity and content

- Summary

- Abstract

- Description

- Claims

- Application Information

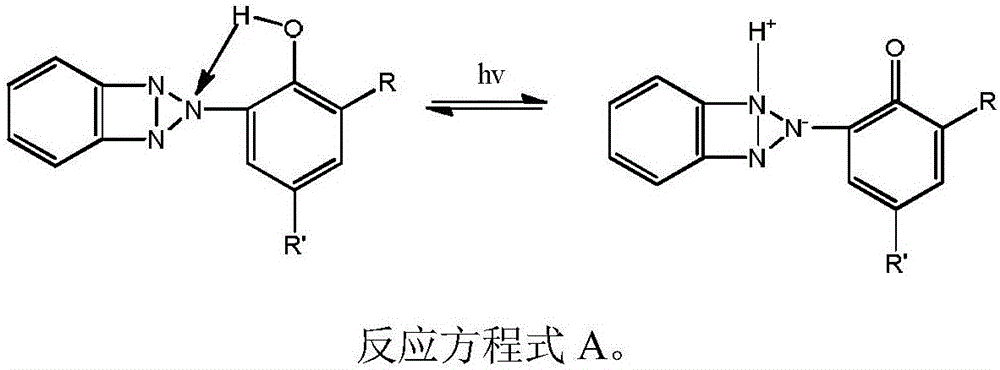

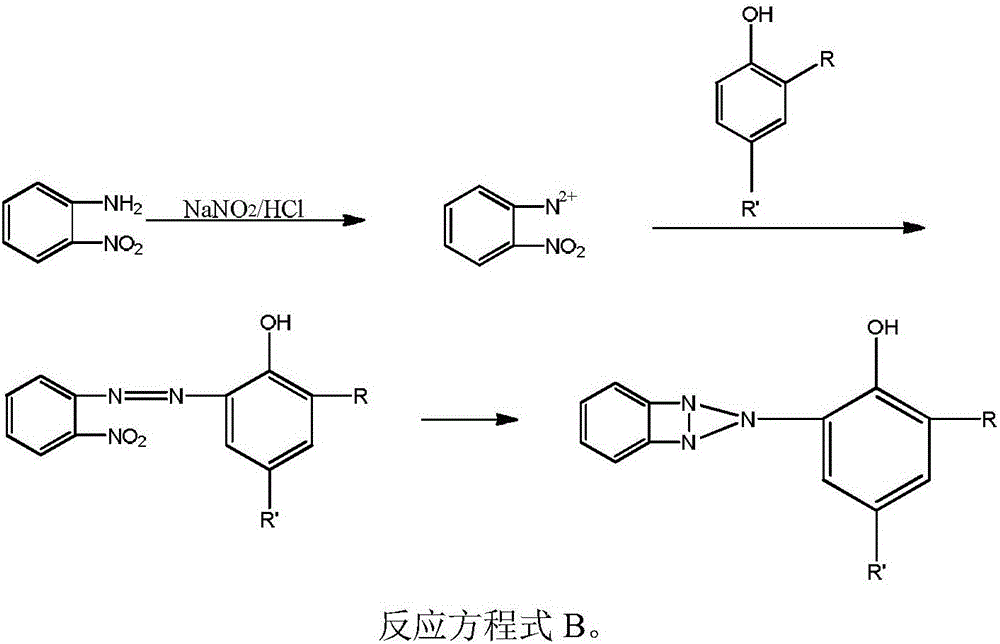

AI Technical Summary

Problems solved by technology

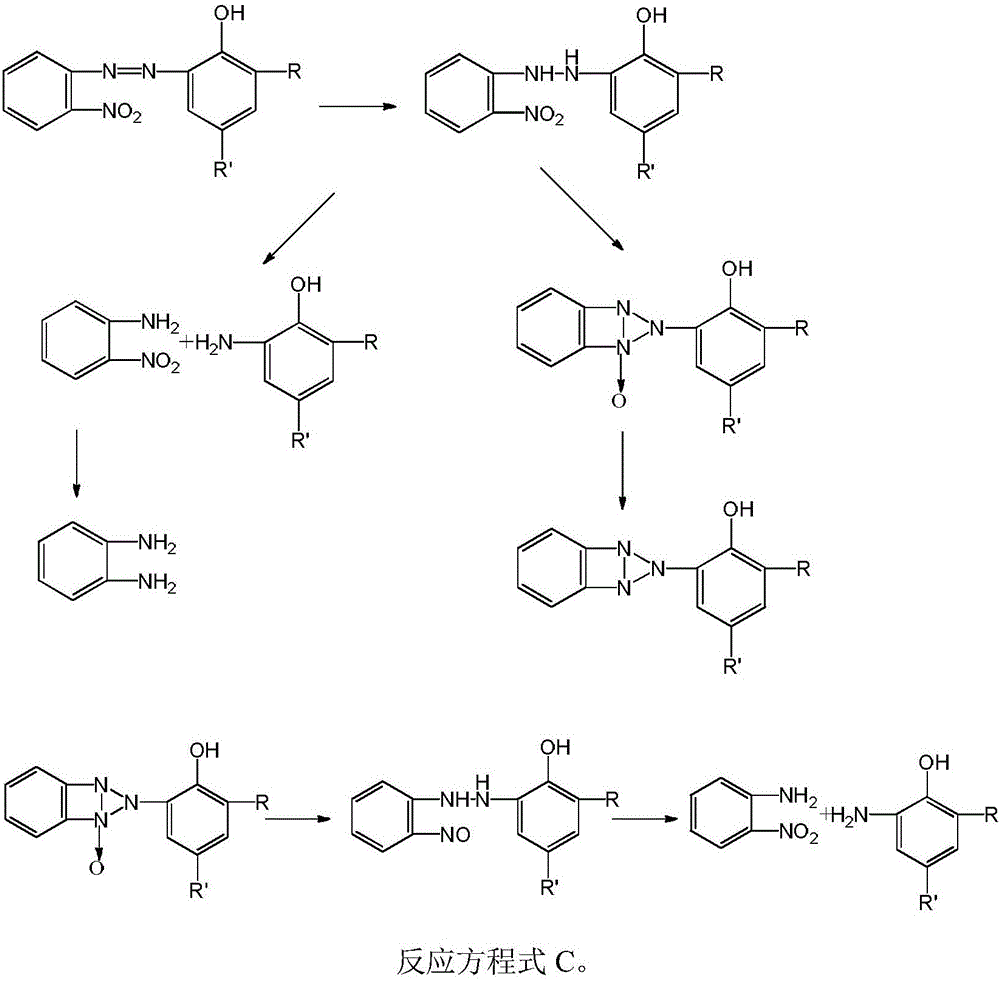

Method used

Image

Examples

Embodiment 1-4

[0041] Embodiment 1-4: a kind of preparation method of benzotriazole ultraviolet absorber, comprises the following steps:

[0042] Step 1: Add the azo dye intermediate shown in formula I, alkali, and the first solvent into the reactor; control the temperature at 60-80°C, slowly add hydrazine hydrate drop by drop for at least 30 minutes, and stir 1~4 hours; Sampling HPLC detects, as the residual amount of the azo dye intermediate shown in formula I is lower than 0.5wt% of its initial charging amount, the reduction reaction of hydrazine hydrate is completed;

[0043] Step 2: add sulfuric acid (or hydrochloric acid) to the mixed solution obtained in step 1 to neutralize the system until the pH of the system is 6 to 7, let stand to separate and take the oil phase, wash the oil phase with water to obtain the intermediate nitrogen shown in formula II solution of oxides;

[0044] Step 3: Move the solution of the intermediate nitrogen oxide shown in the formula II obtained in step 2 to...

Embodiment 5-8

[0051] Embodiment 5-8: a kind of preparation method of benzotriazole ultraviolet absorber, comprises the following steps:

[0052] Step 1: Add the azo dye intermediate shown in formula I, alkali, and the first solvent into the reactor; control the temperature at 60-80°C, slowly add hydrazine hydrate drop by drop for at least 30 minutes, and stir 1~4 hours; Sampling HPLC detects, as the residual amount of the azo dye intermediate shown in formula I is lower than 0.5wt% of its initial charging amount, the reduction reaction of hydrazine hydrate is completed;

[0053] Step 2: add sulfuric acid (or hydrochloric acid) to the mixed solution obtained in step 1 to neutralize the system until the pH of the system is 6 to 7, let stand to separate and take the oil phase, wash the oil phase with water to obtain the intermediate nitrogen shown in formula II solution of oxides;

[0054] Step 3: move the solution of the intermediate nitrogen oxide shown in the formula II obtained in step 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com