System and method for automatic control of ethanol recovery

A technology of automatic control and recovery system, applied in chemical instruments and methods, separation methods, distillation adjustment/control, etc., can solve the problems of energy consumption, zero emission, low ethanol recovery rate, etc., and achieve distillation process. Stable and no fluctuation, save steam consumption, improve the effect of distillation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

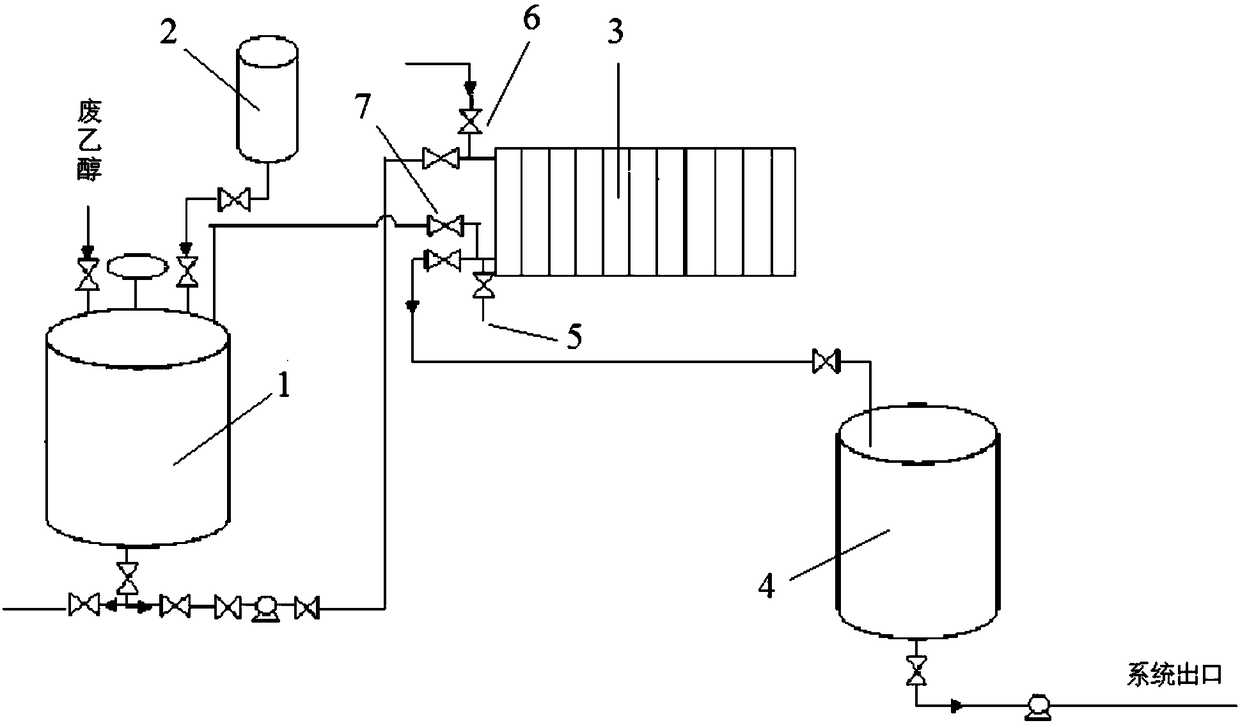

[0031] Such as figure 1 , 2 As shown, the ethanol recovery automatic control system includes an ethanol waste liquid pretreatment system and an ethanol recovery system, and the outlet of the ethanol waste liquid pretreatment system is connected to the inlet of the ethanol recovery system.

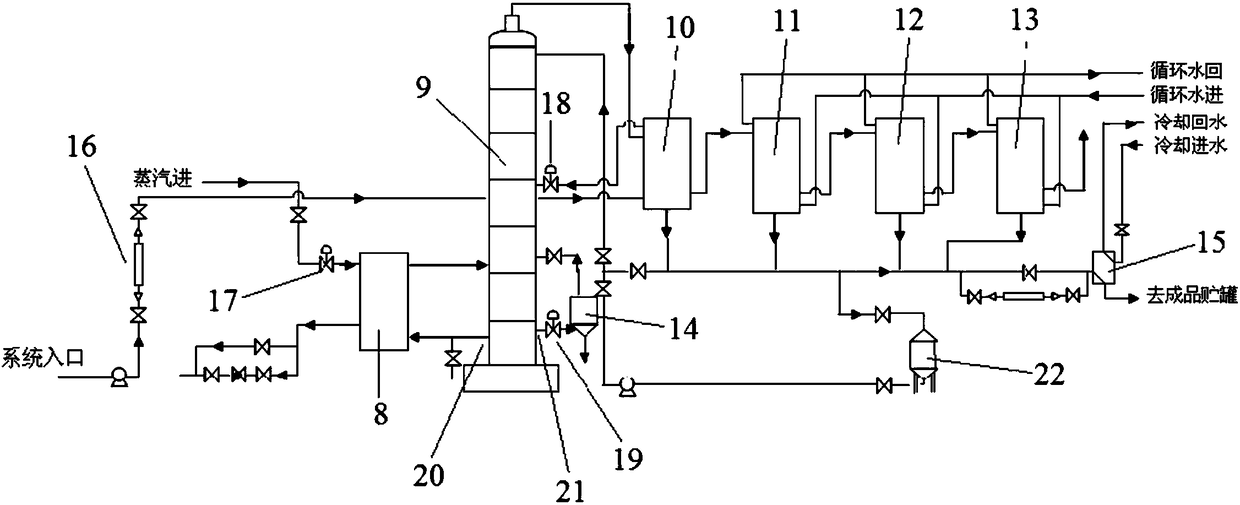

[0032] The ethanol recovery system includes a reboiler 8, an ethanol distillation tower 9, a preheater 10, a vapor-liquid separator 14, a condensation system, and a finished product cooler 15; the liquid outlet of the preheater 10 passes through the liquid inlet of the pipeline and the ethanol distillation tower 9 The steam outlet of the ethanol distillation tower 9 is connected with the steam inlet of the preheater 10, the steam outlet of the preheater 10 is connected with the steam inlet of the condensing system, and the condensate outlet of the preheater 10 and the condensing system is connected with the finished product cooler 15 The inlet of the ethanol distillation tower 9 is provide...

Embodiment 2

[0042] Embodiment 1 is further described in this implementation, the ethanol recovery system also includes a reflux tank 22, the liquid outlet of the preheater 10 and the first condenser 11 is connected to the inlet of the reflux tank 22, and the outlet of the reflux tank 22 passes through a pipeline and ethanol distillation The ethanol reflux port of tower 9 is connected.

Embodiment 3

[0044] The method of automatic control of ethanol recovery: the waste ethanol is pretreated in the pretreatment system before entering the ethanol recovery distillation system for distillation. The pretreatment is to neutralize the waste ethanol coarse crystal mother liquor, and then filter the sediment through the filter plate frame; The pH of the mixed waste liquid is 6.7-7.2.

[0045] The distillation process is as follows: the steam enters the ethanol distillation tower through the reboiler to preheat the tower body, and at the same time control the steam pressure, the steam pressure is controlled at 0.04 ~ 0.05Mpa, after the tower body is preheated, the condensation system is turned on, and the pretreated The waste ethanol liquid is preheated by the preheater and enters the ethanol distillation tower for distillation. At the same time, the liquid flow is controlled. The waste ethanol flow is controlled at 3.5-5.0m 3 / h, and adjust and control the temperature of the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com