Mixture containing slow-release saline compound, composite phase-change material and asphalt and preparation method of mixture

A technology of composite phase change material and asphalt mixture, which is applied in the field of pavement materials, can solve the problems of high cost of materials, poor deicing and snow removal effect, and difficult construction, and achieves low cost of materials, reduction of snow removal times, and low construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

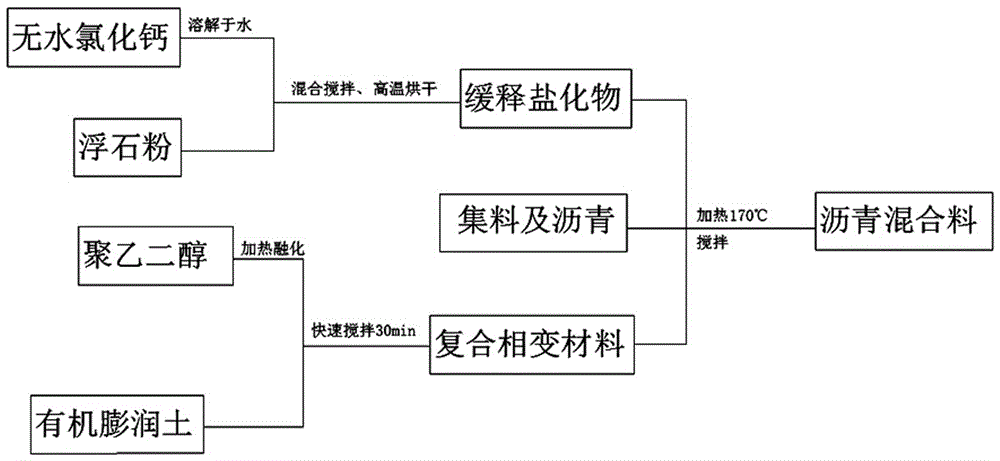

Method used

Image

Examples

Embodiment 1

[0030] This slow-release salt composite phase change material asphalt mixture includes the following components by weight:

[0031] Slow release salt: 2 parts, composite phase change material: 0.75 parts, asphalt: 5 parts, auxiliary materials: 102 parts.

[0032] The fineness of the slow-release salt compound is 200 mesh.

[0033] In this embodiment, the chlorine salt in the slow-release salt compound is anhydrous calcium chloride, the pumice powder is volcanic rock powder, and the mass ratio of anhydrous calcium chloride to volcanic rock powder is 4:1.

[0034] Certainly in other embodiments, the chloride salt may be potassium chloride or sodium chloride or the like.

[0035] In this embodiment, the composite phase change material is composed of polyethylene glycol and organic bentonite, wherein the organic bentonite accounts for 5% of the weight of polyethylene glycol.

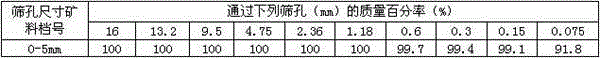

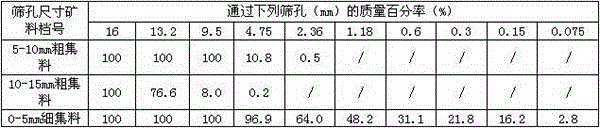

[0036] The auxiliary materials include the following components by weight: 52 parts of coarse aggregate...

Embodiment 2

[0042] This slow-release salt composite phase change material asphalt mixture includes the following components by weight:

[0043] Slow release salt: 3 parts, composite phase change material: 0.9 parts, asphalt: 6 parts, auxiliary materials: 104.2 parts.

[0044] The fineness of the slow-release salt compound is 200 mesh.

[0045] In other embodiments, the fineness of the slow-release salt compound can also be any one of 150-300 mesh.

[0046] In this embodiment, the chlorine salt in the slow-release salt compound is anhydrous calcium chloride, the pumice powder is volcanic rock powder, and the mass ratio of anhydrous calcium chloride to volcanic rock powder is 6:1.

[0047] In other embodiments, the chloride salt may be potassium chloride or sodium chloride, etc.

[0048] In this embodiment, the composite phase change material is composed of polyethylene glycol and organic bentonite, wherein the organic bentonite accounts for 9% by weight of polyethylene glycol.

[0049] Th...

Embodiment 3

[0056] In this example, slow-release salt: 2.5 parts, composite phase change material: 0.8 parts, asphalt: 5.1 parts, auxiliary materials: 103.1 parts.

[0057] The fineness of the slow-release salt compound is 200 mesh.

[0058] In other embodiments, the fineness of the slow-release salt compound can also be any one of 150-300 mesh.

[0059] In the present embodiment, the auxiliary materials include the following components by weight: 52 parts of coarse aggregate, 49 parts of fine aggregate, and 2.1 parts of mineral powder.

[0060] In this embodiment, the raw materials used for the slow-release salt compound and the composite phase change material are as follows.

[0061] Chloride, adopts the anhydrous calcium chloride that Beijing Compu Huiwei Technology Co., Ltd. produces; The number of shares is 65 parts.

[0062] The pumice powder is pumice powder produced by Shangyi County Wanjing Pumice Technology Co., Ltd., the specification is volcanic stone powder (red), and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com