A kind of environmentally friendly reinforced concrete rust inhibitor and its application

A reinforced concrete, environment-friendly technology, applied in the field of rust inhibitors, can solve the problems of lack of strong evidence for corrosion inhibitors, decrease in concrete compressive strength, short action time of corrosion inhibitors, etc., to reduce the rate, improve service life, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

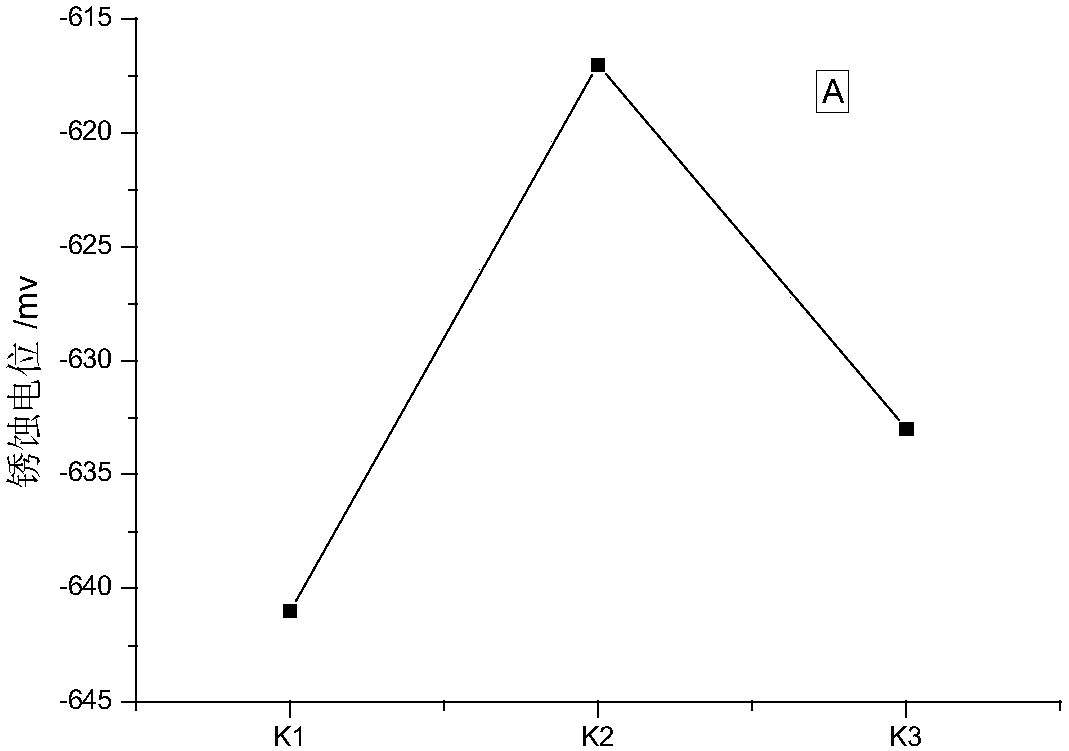

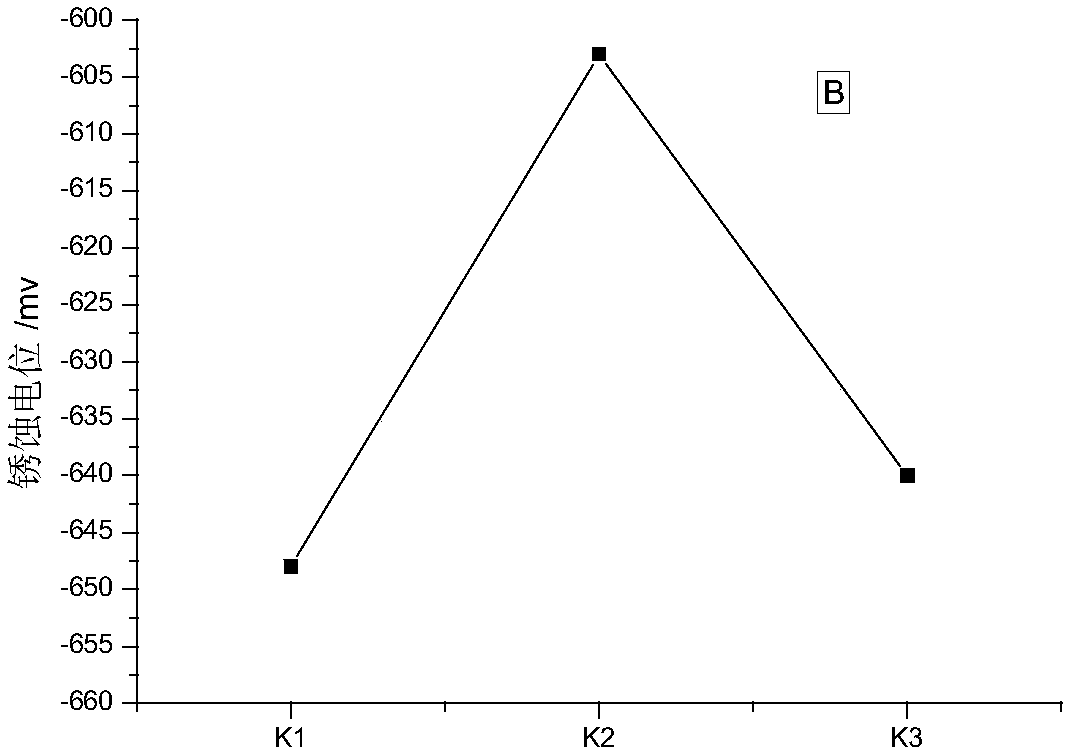

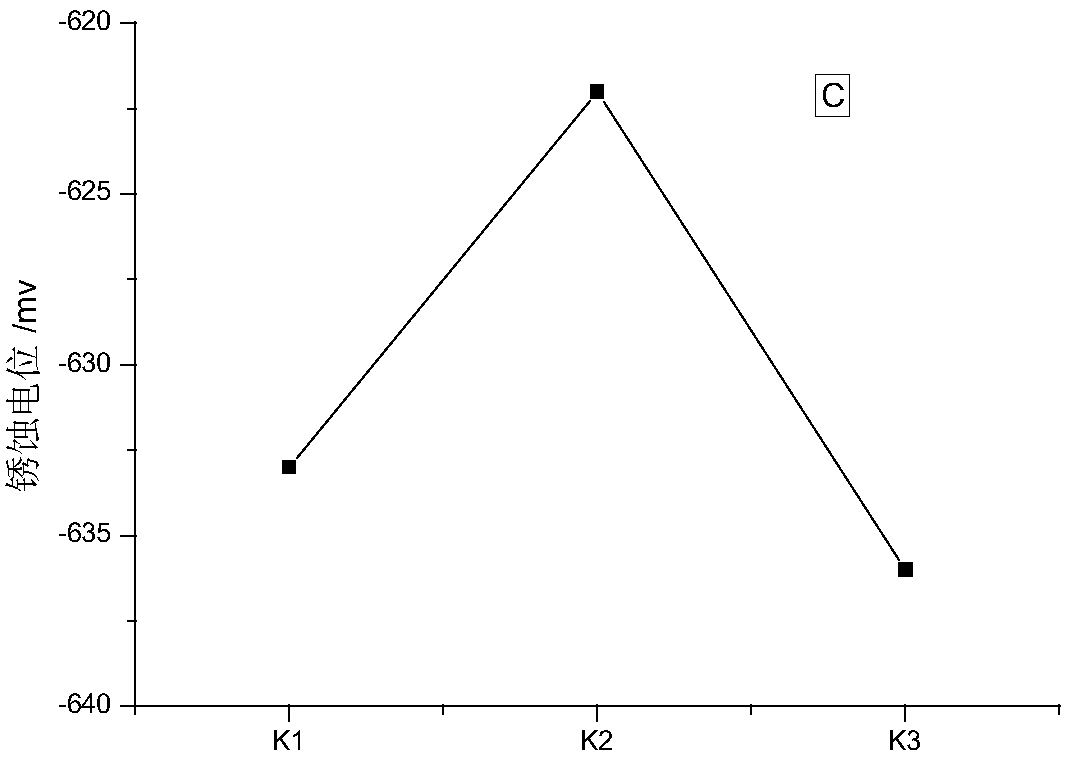

[0025] Example 1: Rust inhibitor of the present invention

[0026] The formulation of the rust inhibitor is: by mass percentage, 0.5% of sodium molybdate, 0.3% of zinc sulfate, 1.0% of triethanolamine, and the rest is water. The rust inhibitor of the present invention was prepared by mixing various components, and the slow release effect of the rust inhibitor formulated in this example and its influence on concrete properties were evaluated respectively by the above-mentioned method. The results are shown in Table 1.

Embodiment 2

[0027] Example 2: Rust inhibitor of the present invention

[0028] The formulation of the rust inhibitor is: by mass percentage, 0.8% of sodium molybdate, 0.5% of zinc sulfate, 0.5% of triethanolamine, and the rest is water. The rust inhibitor of the present invention was prepared by mixing various components, and the slow release effect of the rust inhibitor formulated in this example and its influence on concrete properties were evaluated respectively by the above-mentioned method. The results are shown in Table 1.

Embodiment 3

[0029] Example 3: Rust inhibitor of the present invention

[0030] The formulation of the rust inhibitor adopts: by mass percentage, 0.3% of sodium molybdate, 0.8% of zinc sulfate, 1.2% of triethanolamine, and the rest is water. The rust inhibitor of the present invention was prepared by mixing various components, and the slow release effect of the rust inhibitor formulated in this example and its influence on concrete properties were evaluated respectively by the above-mentioned method. The results are shown in Table 1.

[0031] Table 1 List of rust inhibitor test results

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com