Hydrated calcium borate microsphere and anhydrous calcium borate microsphere, and preparation methods thereof

A calcium borate hydrate, calcium borate technology, applied in borates, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of product particle stability deviation, insufficient pore structure, wide diameter distribution, etc., to achieve mild conditions, Low cost and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of calcium borate hydrate microspheres, comprising the following steps:

[0027] (1) mixing calcium salt, alkali source and water to obtain a mixed slurry;

[0028] (2) mixing the mixed slurry obtained in the step (1) with a surfactant to obtain a mixed solution;

[0029] (3) The mixed solution obtained in the step (2) is mixed with a boron source, and hydrothermally reacted to obtain hydrated calcium borate microspheres.

[0030] The present invention mixes calcium salt, alkali source and water to obtain mixed slurry. In the present invention, there is no special limitation on the mixing operation, and the method for preparing the mixed slurry well known to those skilled in the art can be used. In the present invention, the calcium salt is preferably mixed with water to obtain a calcium salt solution; then the calcium salt solution is mixed with alkali to obtain a mixed slurry. In the present invention, the mixing is prefe...

Embodiment 1

[0046] (1) Add 10 mL of deionized water into a beaker filled with 5 mmol of calcium nitrate solid, and stir magnetically at a speed of 400 rpm / min for 10 min to obtain a mixed solution;

[0047] (2) Dilute 10mL of 1mol·L -1 Add the KOH solution dropwise to the mixed solution at a rate of 3mL / min, and continue to stir at a speed of 400rpm / min for 10min to obtain a mixed slurry;

[0048] (3) Add 0.3125mmol EDTA-2Na solid into the mixed solution obtained in (2), and stir at 400rpm / min for 5min;

[0049] (4) 30mL containing 20mmol of H 3 BO 3 The solution was dripped into the mixed solution obtained in (3) at a rate of 3 mL / min, and continued to stir at a speed of 400 rpm / min for 15 min to obtain a hydrothermal precursor;

[0050] (5) Transfer the hydrothermal precursor to the hydrothermal reaction kettle, raise the temperature to 210°C at a heating rate of 10°C / min, keep the temperature for 1.0h, and then naturally cool to room temperature to obtain the hydrothermal product; ...

Embodiment 2

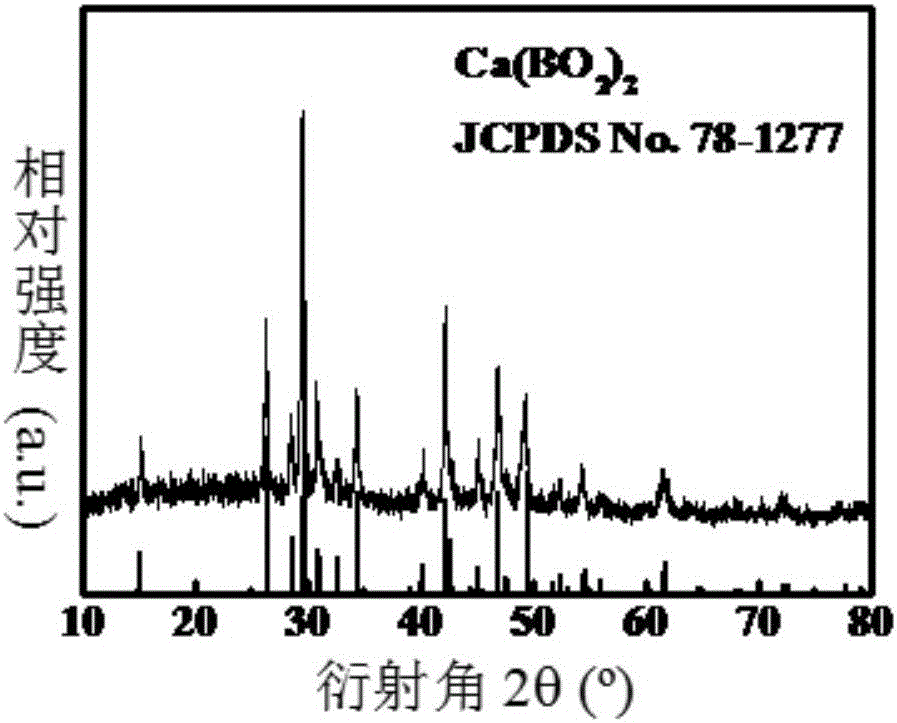

[0055] The hydrated calcium borate (Ca 4 B 10 o 19 ·7H 2 O) The microspheres are placed in a tube furnace, heated to 750°C at a heating rate of 10°C / min, calcined for 1.0h, and then naturally cooled to room temperature to obtain Ca(BO 2 ) 2 Microspheres.

[0056] The Ca(BO) prepared in this embodiment 2 ) 2 Microsphere XRD patterns such as image 3 shown. It can be seen from the figure that Ca(BO 2 ) 2 The XRD patterns of the microspheres match well with the XRD standard card JCPDS No.78-1277, and have very good crystallinity.

[0057] The Ca(BO) prepared in this embodiment 2 ) 2 The microsphere has a multi-level porous structure, the particle size is 9-14 μm, and the particle size distribution is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com