Automatic metal net filter layer winding machine and metal net filter layer winding method

A metal mesh and winding machine technology, applied in the field of machinery, can solve problems such as manual control error, unstable product performance, poor product consistency, etc., to save trimming procedures, improve work efficiency and work quality, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

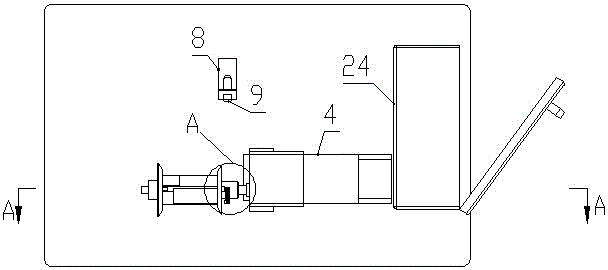

[0031] Such as Figure 1 to Figure 7 As shown, the automatic metal mesh filter layer winding machine of the present invention includes a panel 1, and the panel 1 is provided with four legs downwards, including two front legs 21 and two rear legs 22; between the two front legs 21 Three horizontally arranged tension rods 3 are connected up and down at intervals;

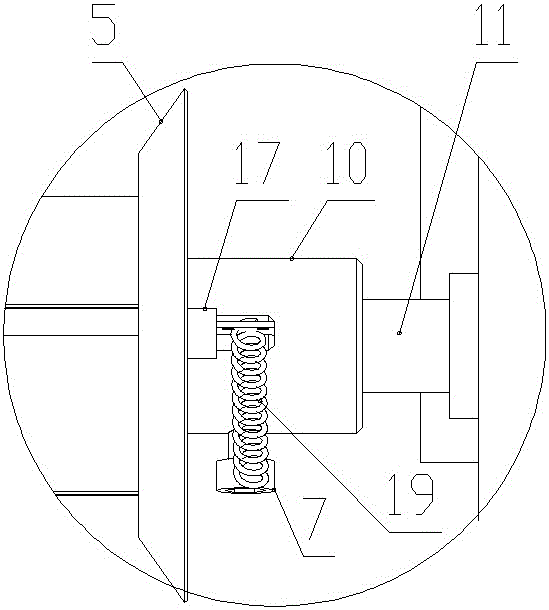

[0032] The frame panel 1 is provided with a winding reduction motor 4, the output shaft of the winding reduction motor 4 is fixedly connected with a compression winding device, and the compression winding device is provided with fixed winding wheels for limiting the winding width of the metal mesh filter layer at an axial interval. 5 and the movable winding wheel 6, a magnetic material block 7 is provided on the compression winding device on the side of the fixed winding wheel 5 away from the movable winding wheel 6;

[0033] The panel 1 behind the pressing and winding device is provided with a sensor bracket 8, and a magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com