Feeding disc for small hardware

A technology for small hardware parts and feeding trays is applied in the field of hardware parts preparation to achieve the effects of high feeding accuracy, fast processing, and improved effective speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

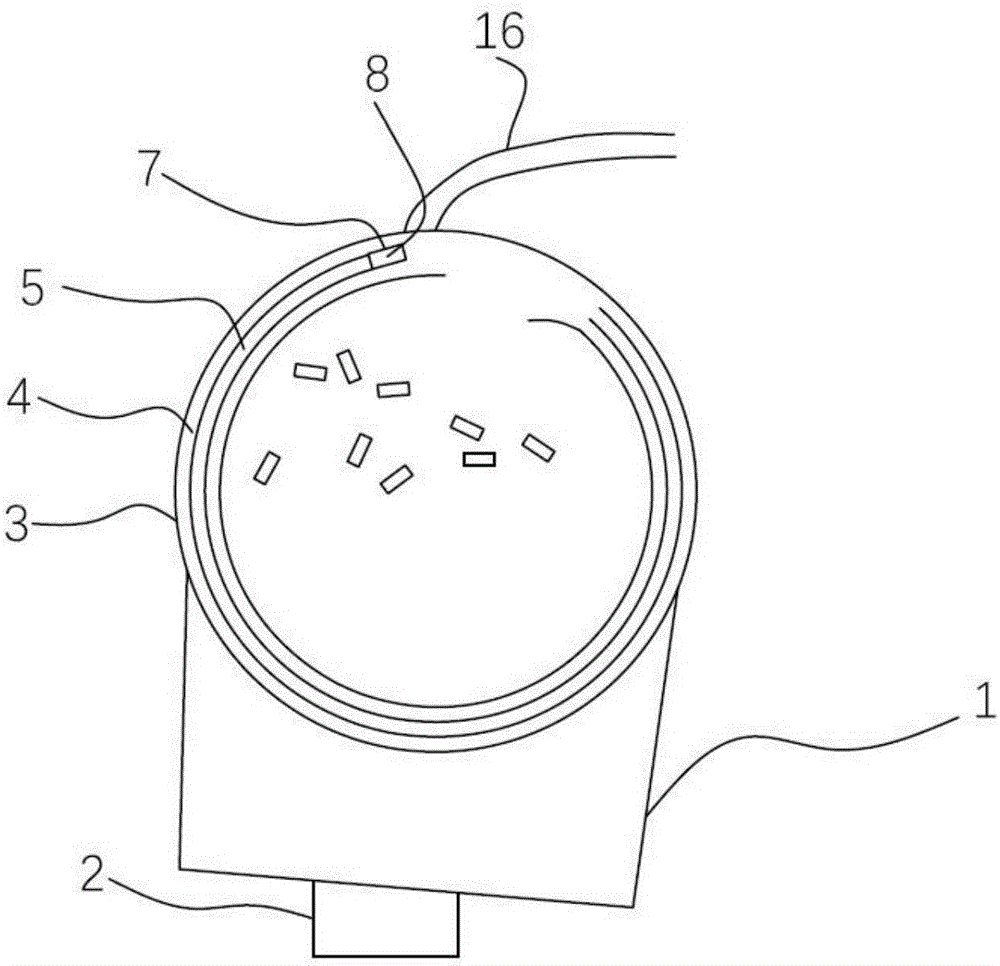

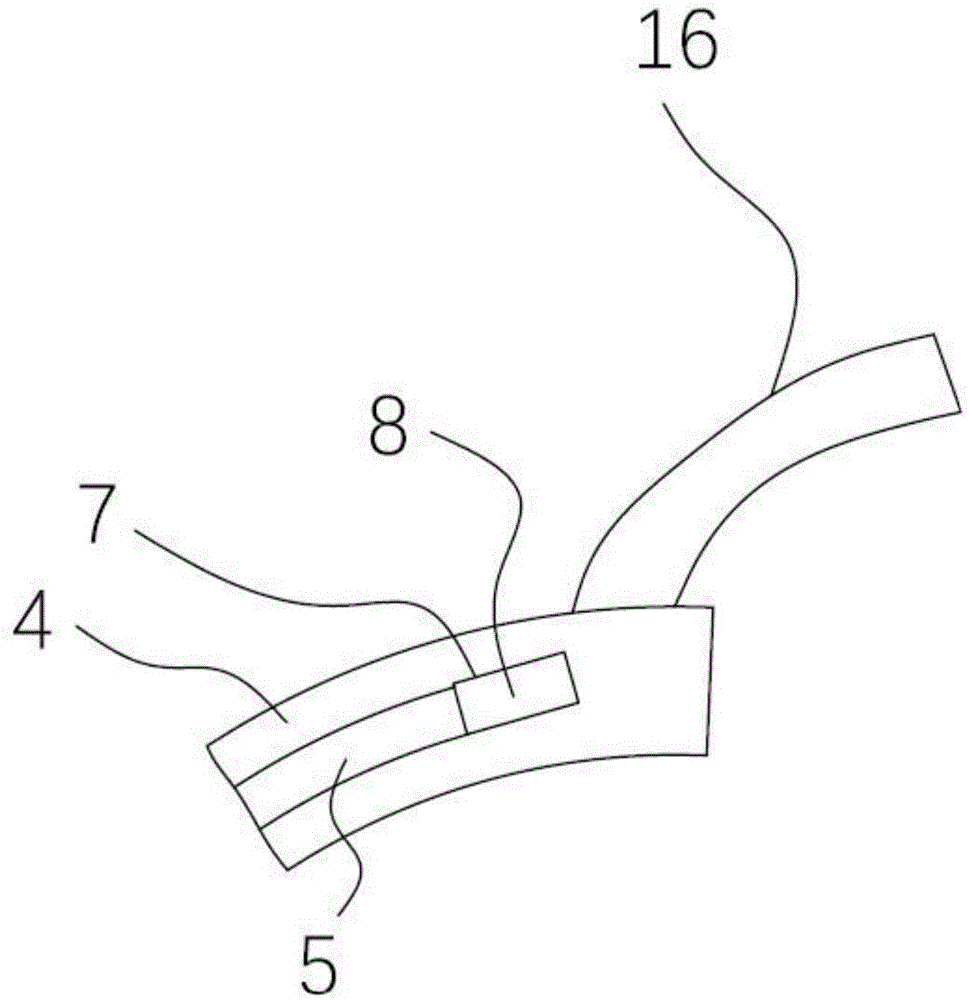

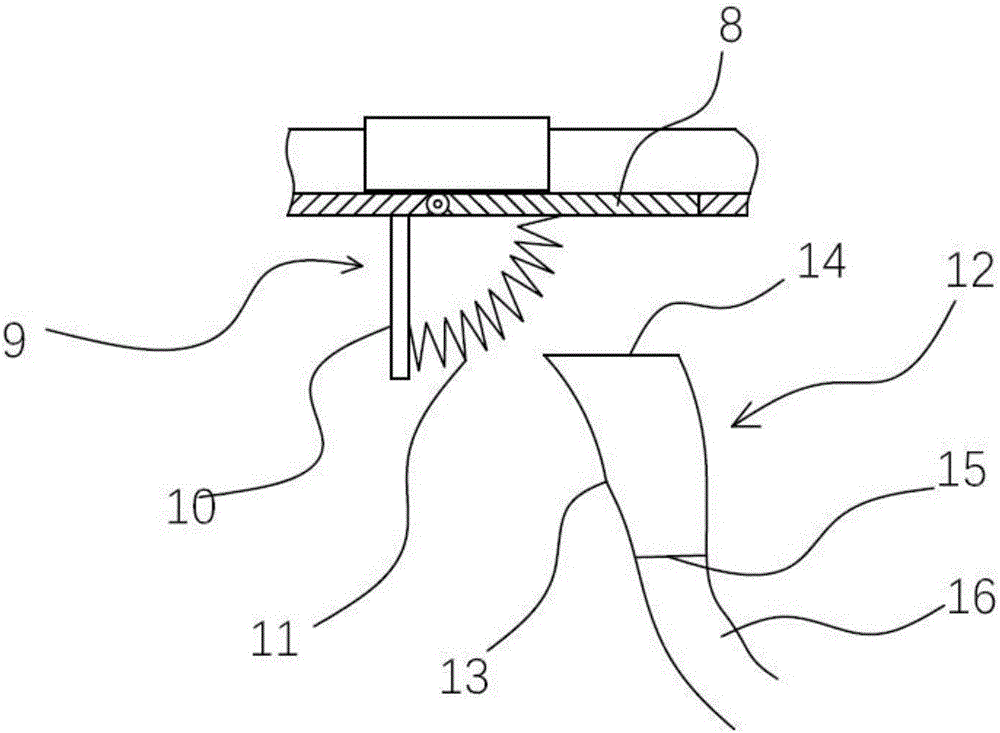

[0029] A feeding tray for small hardware, such as figure 1 As shown, it includes a base 1 on which a vibrator 2 is set, a feeding hopper 3 is arranged on the base 1, and a spirally rising feeding channel 4 is arranged on the inner wall of the feeding hopper 3, and a feeding channel 5 is provided on the feeding channel 4 along its rising direction, and the feeding channel 5 is Arc-shaped groove, the width of feeding groove 5 matches the width of small hardware, such as Figure 4 , 5 , 6, the bottom of the feeding trough 5 is provided with some parallel stripes 6, as Figure 4 As shown, the stripes 6 are arranged laterally along the rising feeding chute 5, as Figure 5 As shown, the stripes 6 are longitudinally arranged along the rising feeding trough 5; as Figure 6 shown in Figure 4 On the basis of , divide several stripes 6 into one group, and arrange them at intervals in the form of groups. In order to reduce friction, (not marked in the figure), the bottom of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com