Recovery system of gypsum board sticky and wet waste

A recycling system, gypsum board technology, applied in the direction of solid waste removal, grain processing, etc., can solve the problems of production interruption, environmental pollution, industrial waste occupying storage space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

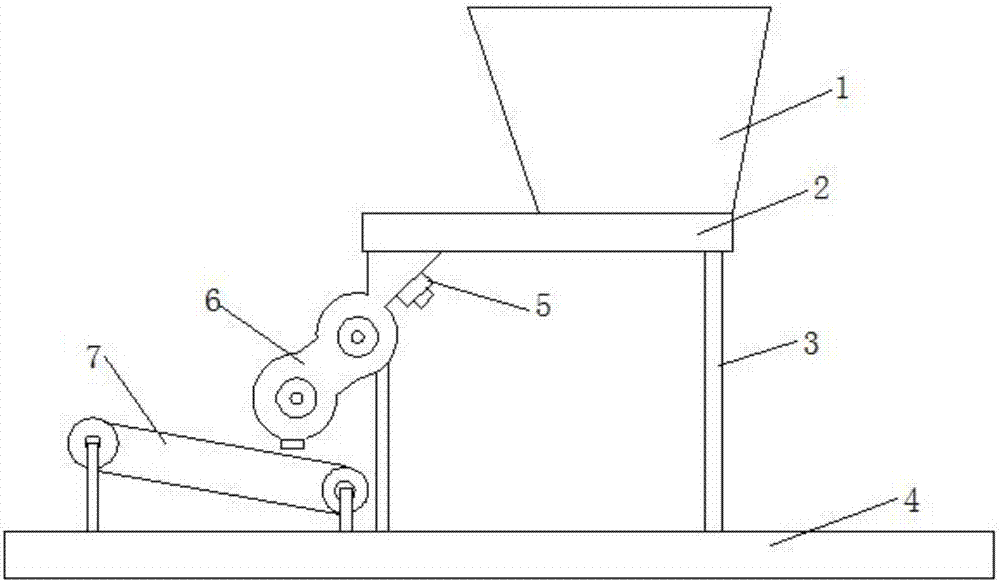

[0017] Example 1: Reference figure 1 , the gypsum board viscous and wet waste recovery system of the present invention includes a material injection funnel 1, the lower end of the material injection funnel 1 is connected with a U-shaped screw conveyor 2, and the U-shaped screw conveyor 2 transports the waste to the two-stage crushing unit 6, and the two-stage crushing A vibrating device 5 is installed at the feeding port of the unit 6, and the double-stage crushing unit 6 discharges the crushed materials on the belt conveyor 7, and the belt conveyor 7 transports the crushed materials to the raw material bin to enter the calcination process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com