Combined type woodworking engraving machine of multi-station dust removing device

A technology of dust removal device and engraving machine, which is applied in decorative arts, painting tools, processing models, etc., can solve the problems of cost increase, reduction of engraving precision, loss, etc., and achieve the effects of improving processing efficiency, easy maintenance and management, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

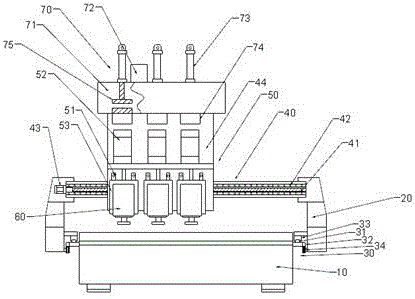

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0015] A woodworking engraving machine with a combined multi-station dust removal device, including a machine platform 10 for carrying objects to be carved and a frame 20 straddling the machine platform 10, and also includes a drive frame 20 along the machine platform 10 The Y-axis traveling mechanism 30 traveling longitudinally, the X-axis traveling mechanism 40 traveling horizontally along the frame 20, and the Z-axis traveling mechanism 50 vertically traveling on the X-axis traveling mechanism 40 also include an aluminum plate 53 and a plurality of engraving machine spindles. 60 is fixed on the aluminum plate 53, each engraving machine main shaft 60 is driven by the Z-axis traveling mechanism 50 to realize independent lifting, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com