a 3d printer

A 3D printer and print head technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of reduced accuracy of printed items, decreased acceleration and deceleration performance of nozzles, and prone to position deviation, etc., to achieve fast printing and upgrade Printing speed and precision, the effect of high printing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

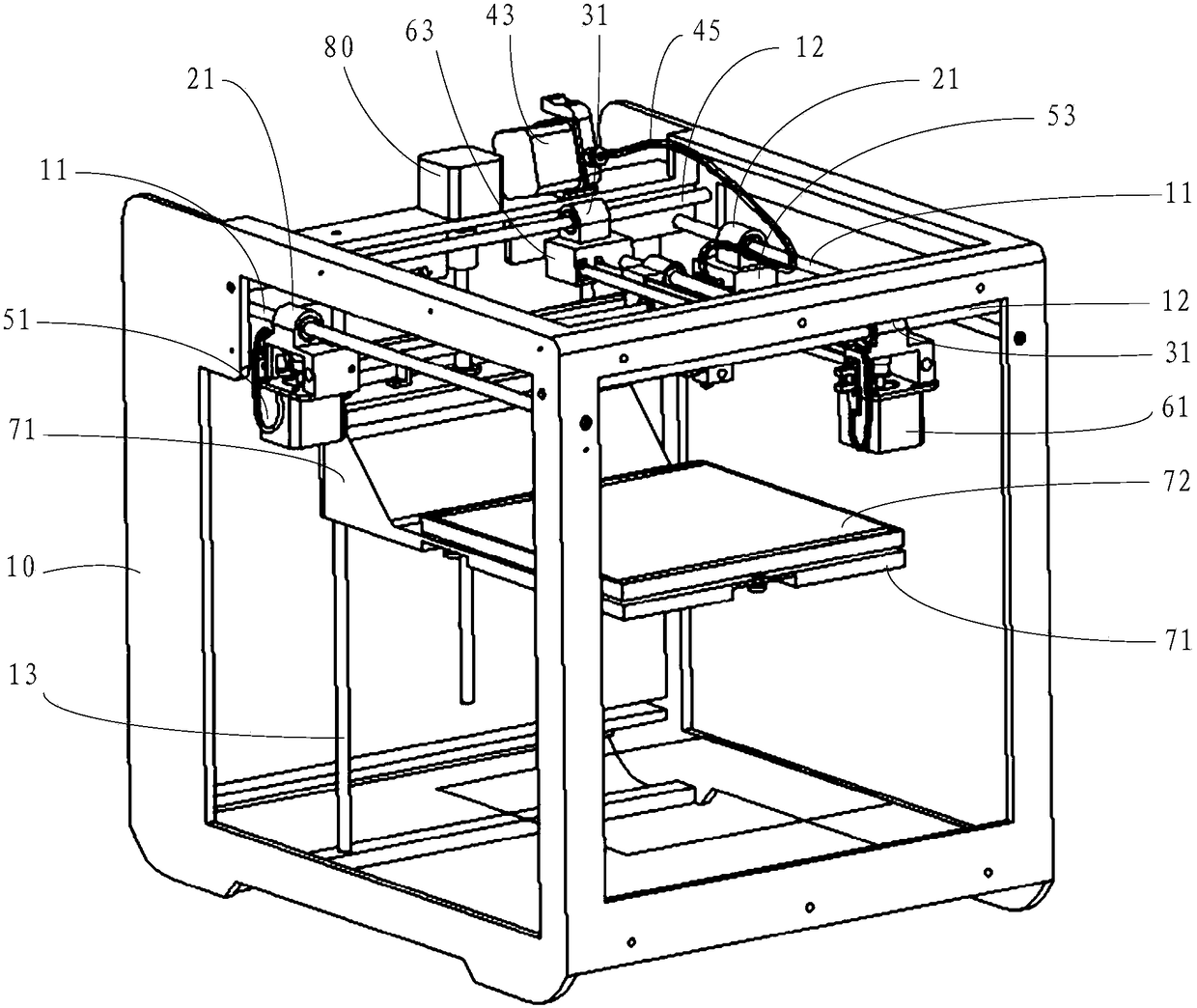

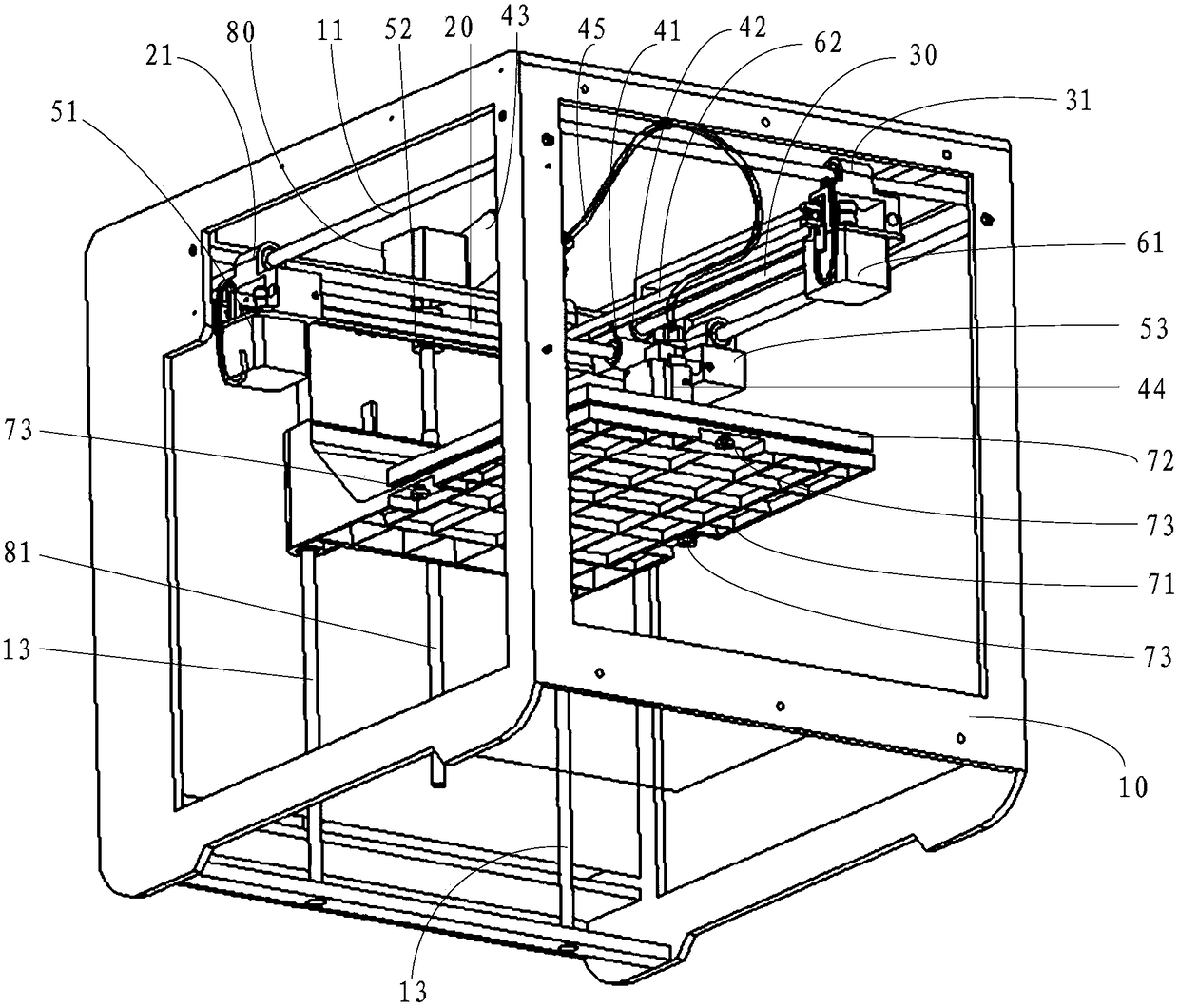

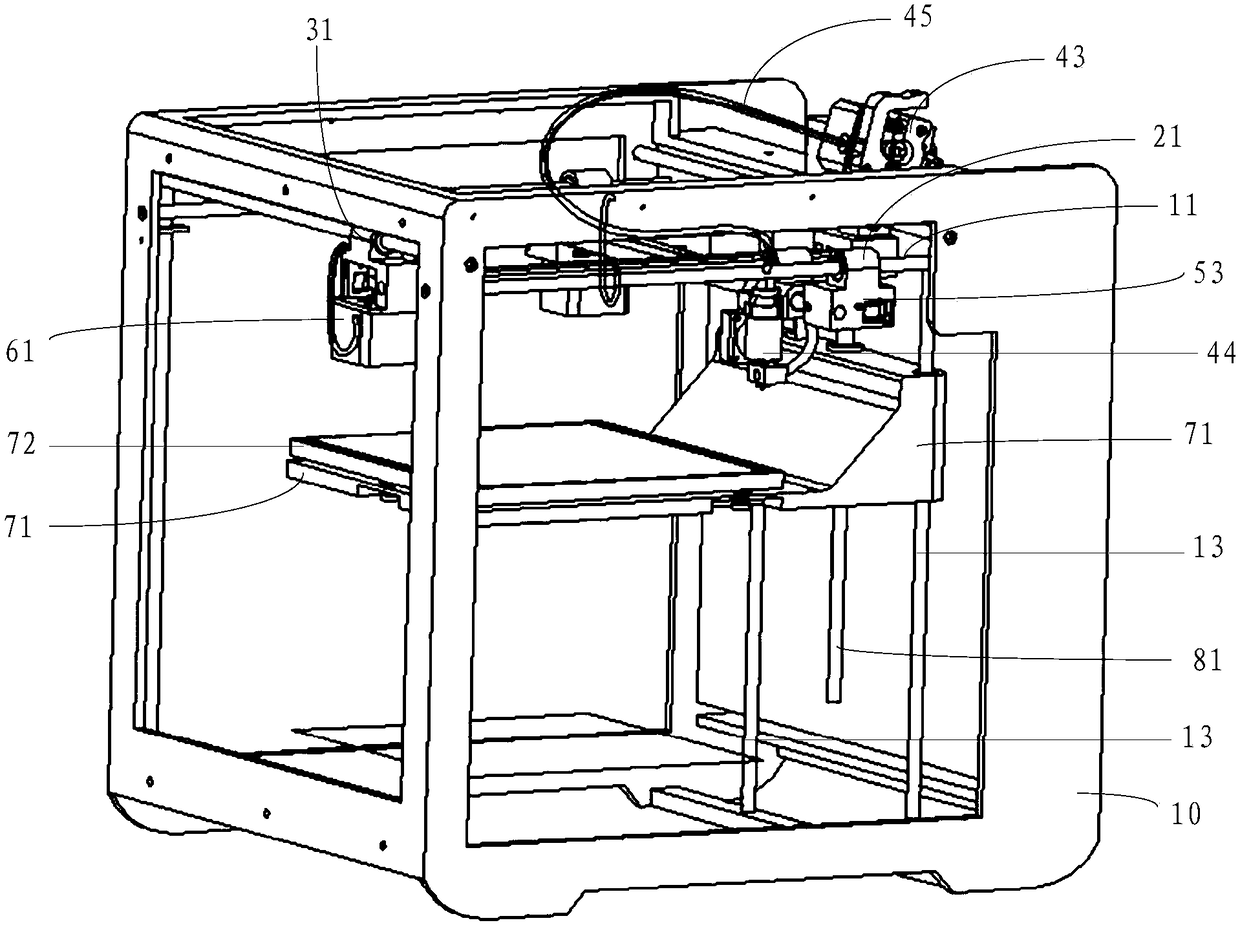

[0032] Such as Figure 1-3 As shown, the 3D printer of the present invention includes a frame 10, a first guide shaft 20, a second guide shaft 30, a printing head, a first driving mechanism and a second driving mechanism.

[0033]There is an included angle between the first guide shaft 20 and the second guide shaft 30 , and in the embodiment of the present invention, the first guide shaft 20 and the second guide shaft 30 are perpendicular to each other. Both ends of the first guide shaft 20 and both ends of the second guide shaft 30 are slidingly fitted with the frame 10 . The sliding fit includes the mutual sliding fit of the shaft sleeve and the shaft, and the mutual sliding fit of the pulley and the slide rail. The print head is connected with the first guide shaft 20 and the second guide shaft 30, and the print head can move along the first guide shaft 20, and the print head can move along the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com