Electric spark milling method of micro three-dimensional part

A technology of milling and electric discharge, applied in the field of electric discharge processing of micro-three-dimensional parts, can solve the problems of high-precision quality, high-efficiency processing, difficulty in shape compensation, electrochemical machining pollution and corrosion, etc. The effect of solving the problem of tool electrode shape change, realizing EDM processing, and eliminating the problem of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing.

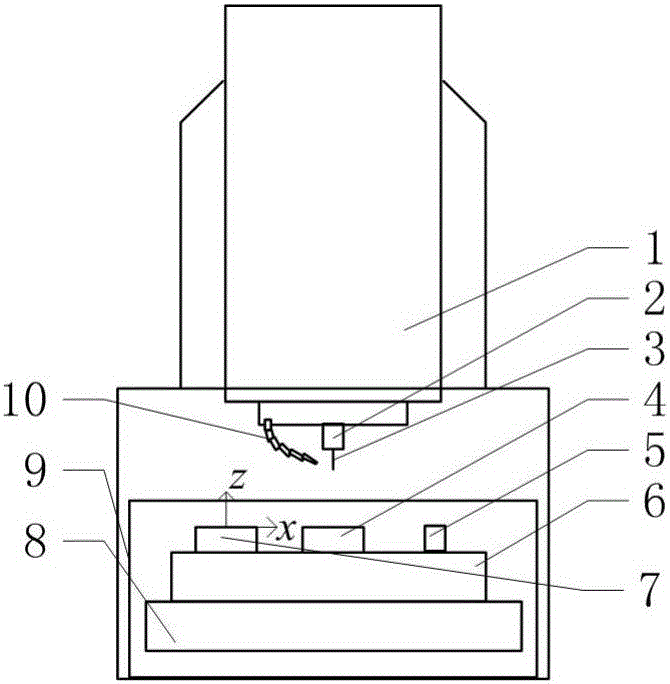

[0049] Such as Figure 1-7 Shown, a kind of electric discharge milling processing method of micro three-dimensional parts, comprises the following steps:

[0050] A. Select the tool electrode 3 suitable for the diameter according to the geometric size of the workpiece 7 to prepare the tool electrode;

[0051] B. Clamp the workpiece 7 and the spare part 4 on the electric discharge forming machine tool 1, and the spare part 4 is made of the same material as the workpiece 7;

[0052] C, if the processed part 7 is a cavity type part 14, then go to step C1; if the processed part 7 is a core type part 21, then go to step C2;

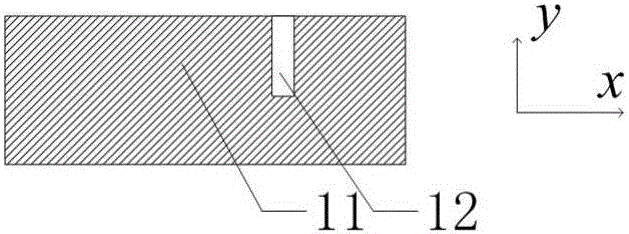

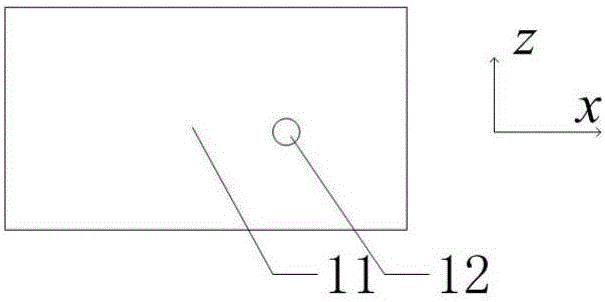

[0053] C1, do pre-processing hole 12 to cavity type parts 14, and use pre-processing hole 12 as the starting point of each layer of processing program, tool electrode 3 enters the bottom of the layer to be processed from the starting point; turn to step D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com