A movable aluminum chip suction machine capable of multi-stage processing

A technology of aluminum chips and blower, which is applied in the direction of cleaning method using gas flow, solid separation, filtering, etc., can solve the problems of high maintenance cost of aluminum chip collection device, time-consuming and laborious manpower recovery, complicated operation, etc., and achieve maintenance cost Inexpensive, highly mobile, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

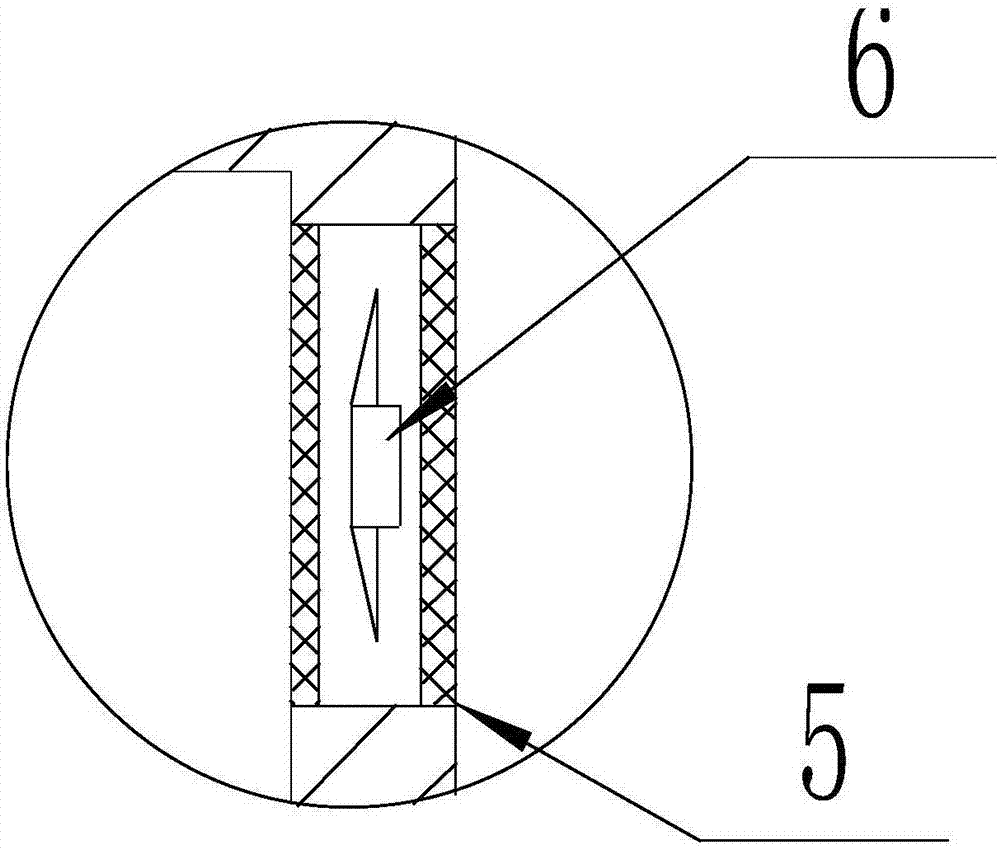

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a movable aluminum chip suction machine capable of multi-stage processing includes a base (1), the upper surface of the base (1) is provided with a circular box (2), and the circular box (2 ), the upper surface of the circular box (2) is processed with a feed port (3), the feed port (3) is provided with a curved tube (4), and the curved tube (4) is processed There is a circular opening (5), a fan (6) is provided in the circular opening (5), a conduit (7) is provided on the curved pipe (4), and a circular box (2) There is a curved barrel (8) on the side, and a circular groove (9) is processed on the inner surface of one end of the curved barrel (8). The circular groove (9) is provided with a rotating end for horizontal rotation The motor (10), the rotating end of the rotating motor (10) is provided with a fan blade (11), the circular groove (9) is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com