Superacid-coated HZSM-5 molecular sieve catalyst and preparation method and application thereof

A technology of molecular sieve and super acid, which is applied in the direction of molecular sieve catalyst, molecular sieve catalyst, catalyst, etc., can solve the problems of destroying the pore structure of HZSM-5 molecular sieve, the decrease of the utilization rate of acid sites in the pore, and the insignificant suppression of surface carbon, so as to improve the work Stability, easy large-scale preparation, and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

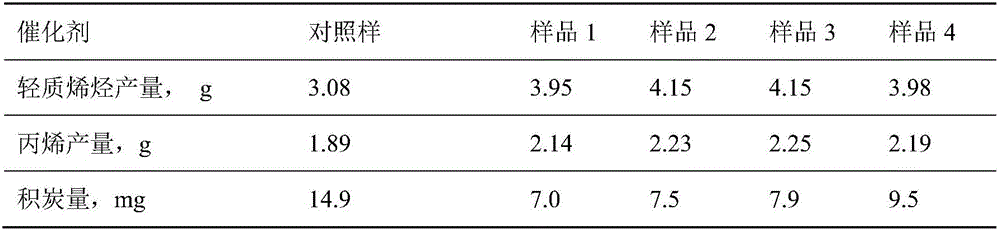

Examples

preparation example Construction

[0022] The preparation method of catalyst of the present invention is as follows:

[0023] In order to prepare the superacid-coated HZSM-5 molecular sieve catalyst, firstly, by adjusting the raw material formula in the chemical liquid phase deposition method, a layer of TiO with controllable quality is deposited on the outer surface of the HZSM-5 molecular sieve grain. 2 or ZrO 2 . Vulcanization is then accomplished in a sulfur-containing solution (sulfuric acid, ammonium sulfate, persulfuric acid, or an aqueous ammonium persulfate solution). By adjusting the concentration of sulfur-containing solution and the time of vulcanization, the TiO 2 and ZrO 2 Different degrees of super-acidification, and then on the outer surface of the HZSM-5 molecular sieve, a layer of adjustable super-acid shell is formed to realize the improvement of the catalytic activity of the HZSM-5 molecular sieve and inhibit the formation of carbon on the surface.

[0024] As mentioned above, the presen...

Embodiment 1

[0026] Example 1: TiO 2 ·H 2 SO 4 Preparation of wrapped HZSM-5

[0027] Dissolve 0.15 g of tetrabutyl titanate in 125 mL of absolute ethanol, add 5 g of commercial HZSM-5 molecular sieves into the solution, and heat and stir for about 1 hour. Next, the solution was filtered, dried, and calcined at 550° C. for 3 hours. Take 100 mL of 10 wt % ammonium sulfate aqueous solution, and add the calcined sample into the solution, and then stir at room temperature for about 8 hours. Next, the solution was filtered, dried, and calcined at 550°C for 3 hours to obtain TiO 2 ·H 2 SO 4 Wrap HZSM-5 catalyst (sample 1).

Embodiment 2

[0028] Example 2: ZrO 2 ·H 2 SO 4Preparation of wrapped HZSM-5

[0029] Under the condition of protective gas, the air was isolated, 0.30 g of zirconium butoxide was dissolved in 125 mL of absolute ethanol, 5 g of commercial HZSM-5 molecular sieves were added to the solution, and stirred for about 1 hour. Next, the solution was filtered, dried, and calcined at 550° C. for 3 hours. Take 100 mL of 2 wt% sulfuric acid aqueous solution, and add the calcined sample into the solution, and then stir at room temperature for about 1 hour. Next, filter, dry the solution, and then calcinate at 550°C for 3 hours to obtain ZrO 2 ·H 2 SO 4 Wrap HZSM-5 catalyst (sample 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com