Method for growing manganese dioxide nano wall film on conductive substrate

A conductive substrate, manganese dioxide technology, applied in the direction of nanotechnology, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of cumbersome production steps, easy agglomeration growth, weak adhesion, etc. Chemical properties, simple preparation method, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Select size 2.5×2.5 cm 2 1. The FTO conductive glass with a thickness of 2.2 mm is the conductive substrate. After the surface of the conductive substrate is cleaned with absolute ethanol, it is washed with deionized water ultrasonically and dried.

[0023] (2) Fully dissolve potassium permanganate in deionized water to prepare a potassium permanganate solution with a molar concentration of 0.20 M; under constant stirring, add 4 ml of a hydrochloric acid solution with a molar concentration of 0.01 M drop by drop Add it to 50ml of potassium permanganate solution, and mix the potassium permanganate solution and hydrochloric acid solution evenly to obtain a reaction solution.

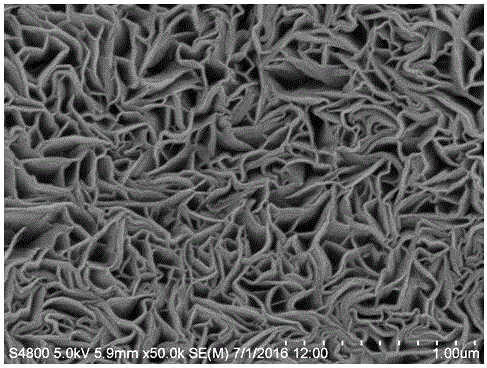

[0024] (3) Immerse the clean conductive substrate obtained in step (1) in the reaction solution prepared in step (2), and react for 72 hours at 40 °C in an electric blast constant temperature drying oven. After the reaction, clean and dry with deionization Ultrasonic vibration washing, and then...

Embodiment 2

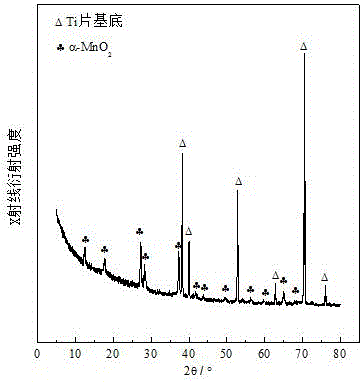

[0027] (1) Select size 2.5×2.5 cm 2 1. A metal titanium sheet with a thickness of 0.1 mm is used as a conductive substrate. After the surface of the conductive substrate is pickled, it is ultrasonically cleaned with deionized water and dried.

[0028] (2) Fully dissolve potassium permanganate in deionized water to prepare a potassium permanganate solution with a molar concentration of 0.15 M; under constant stirring, add 4 ml of a hydrochloric acid solution with a molar concentration of 0.01 M drop by drop Add it to 50 ml of potassium permanganate solution, and mix the potassium permanganate solution and hydrochloric acid solution evenly to obtain a reaction solution.

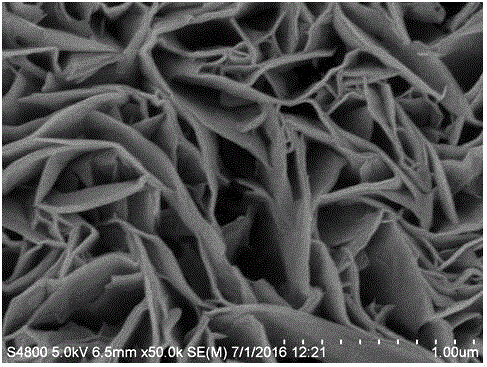

[0029] (3) Immerse the clean conductive substrate obtained in step (1) in the reaction solution prepared in step (2), and react in an electric blast constant temperature drying oven at 60 °C for 48 hours. After the reaction, clean and dry with deionization Ultrasonic vibration washing, and then completely dry ...

Embodiment 3

[0032] (1) Select size 2.5×2.5 cm 2 1. A metal titanium sheet with a thickness of 0.1 mm is used as a conductive substrate. After the surface of the conductive substrate is pickled, it is ultrasonically cleaned with deionized water and dried.

[0033] (2) Fully dissolve potassium permanganate in deionized water to prepare a potassium permanganate solution with a molar concentration of 0.20 M; under constant stirring, add 4 ml of a hydrochloric acid solution with a molar concentration of 0.01 M drop by drop Add it to 50 ml of potassium permanganate solution, and mix the potassium permanganate solution and hydrochloric acid solution evenly to obtain a reaction solution.

[0034] (3) Immerse the clean conductive substrate obtained in step (1) in the reaction solution prepared in step (2), and react for 72 hours at 60 °C in an electric blast constant temperature drying oven. After the reaction, clean and dry with deionization Ultrasonic vibration washing, and then completely dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com